Modern Solutions Driving Change in Heat Exchanger Catalogues

Smart Technologies in Heat Exchanger Catalogue

Smart technologies have transformed the way engineers and decision-makers interact with a heat exchanger catalogue. These advancements help users make faster, more accurate choices. They also improve the overall experience by providing instant access to critical information.

Online Selection Tools

Online selection tools now play a vital role in the modern heat exchanger catalogue. These digital platforms guide users through the process of choosing the right product for their needs. Users enter specific parameters such as flow rate, temperature, and pressure. The tool then generates a list of suitable heat exchangers.

·Engineers save time by avoiding manual calculations.

·The risk of human error decreases.

·Companies can compare multiple models side by side.

Interactive Product Configurators

Interactive product configurators allow users to customize heat exchangers directly within the catalogue. These tools let users adjust dimensions, materials, and connection types. The configurator updates the product model in real time, showing how each change affects performance and compatibility.

·Users can visualize their custom design before placing an order.

·The configurator ensures that all selected options meet industry standards.

·Companies reduce the time spent on back-and-forth communication.

A typical interactive configurator might include:

| Feature | Benefit |

|---|---|

| 3D Visualization | Clear view of product changes |

| Instant Specification | Accurate technical details |

| Export Options | Easy sharing with teams |

Real-Time Performance Data

Access to real-time performance data sets modern heat exchanger catalogues apart from traditional paper-based versions. Users can monitor how a specific model performs under different conditions. This data helps engineers predict how the heat exchanger will behave in their unique application.

·Real-time data supports better decision-making.

·Users can identify potential issues before installation.

·Companies optimize system efficiency and reliability.

Mobile Accessibility

Mobile accessibility has become a defining feature in modern engineering tools. Today’s professionals expect to access technical resources from any location. Mobile-friendly heat exchanger catalogues deliver this flexibility. Engineers can review product data, compare specifications, and even initiate orders directly from smartphones or tablets.

Many companies now offer dedicated mobile apps or responsive web platforms. These solutions ensure that users experience seamless navigation and fast load times on any device. Mobile accessibility supports field engineers who need instant answers while on-site. It also helps project managers who must approve selections during travel.

Key benefits of mobile accessibility include:

·Immediate Access: Users retrieve critical information without returning to their desks.

·Enhanced Collaboration: Teams share product links and data in real time, improving communication.

·Faster Decision-Making: Quick access to catalogues speeds up the selection and approval process.

·Error Reduction: On-the-go access to up-to-date specifications reduces the risk of outdated or incorrect choices.

A mobile-accessible catalogue empowers professionals to stay productive and informed, regardless of their environment. Companies that invest in mobile solutions demonstrate a commitment to efficiency and modern work practices.

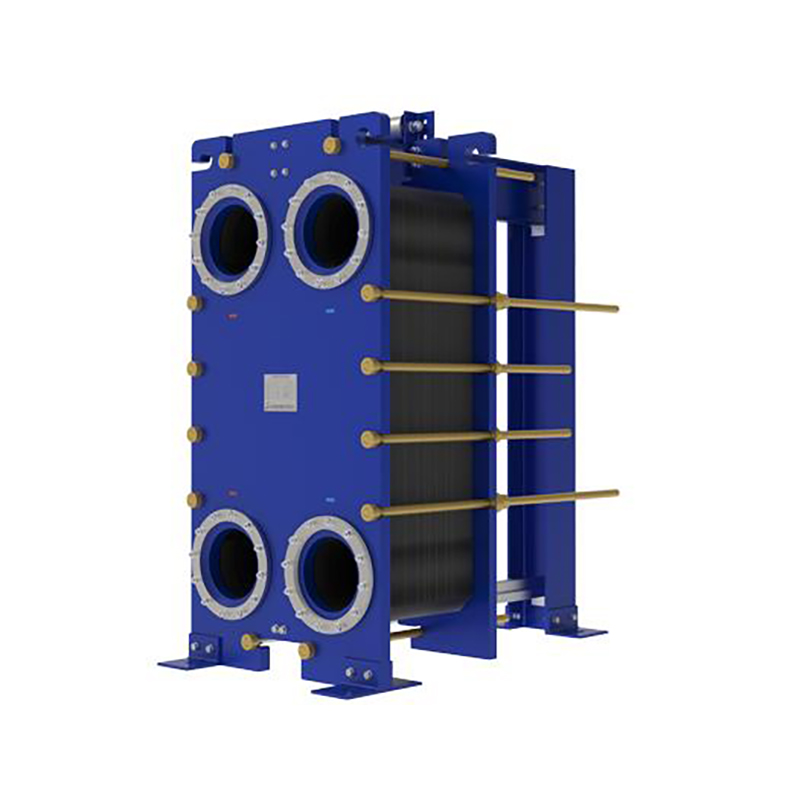

Advanced Materials and Design in Heat Exchanger Catalogue

Modern heat exchangers rely on advanced materials and innovative designs to meet the demands of today’s industries. These improvements help companies achieve higher efficiency, longer service life, and greater flexibility. The latest heat exchanger catalogue highlights these advancements, making it easier for engineers to select the right solution for their projects.

High-Efficiency Alloys

Engineers now use high-efficiency alloys to boost the performance of heat exchangers. These alloys transfer heat more effectively than traditional metals. They also withstand higher temperatures and pressures. Stainless steel, copper-nickel, and titanium alloys have become popular choices.

·Stainless steel resists corrosion and handles extreme conditions.

·Copper-nickel alloys offer excellent thermal conductivity.

·Titanium alloys provide strength and resist chemical attack.

A table below compares some common alloys:

| Alloy Type | Key Benefit | Typical Application |

|---|---|---|

| Stainless Steel | Corrosion resistance | Food processing, HVAC |

| Copper-Nickel | High thermal conductivity | Marine, desalination |

| Titanium | Chemical resistance | Chemical, pharmaceutical |

Corrosion-Resistant Coatings

Corrosion remains a major challenge for heat exchangers, especially in harsh environments. Manufacturers now apply advanced coatings to protect metal surfaces. These coatings extend the lifespan of equipment and reduce maintenance needs.

·Epoxy coatings shield against moisture and chemicals.

·Ceramic coatings resist abrasion and high temperatures.

·Polymer-based coatings provide a lightweight barrier.

Engineers select coatings based on the specific fluids and conditions in each application. The right coating can prevent leaks, reduce downtime, and ensure reliable operation.

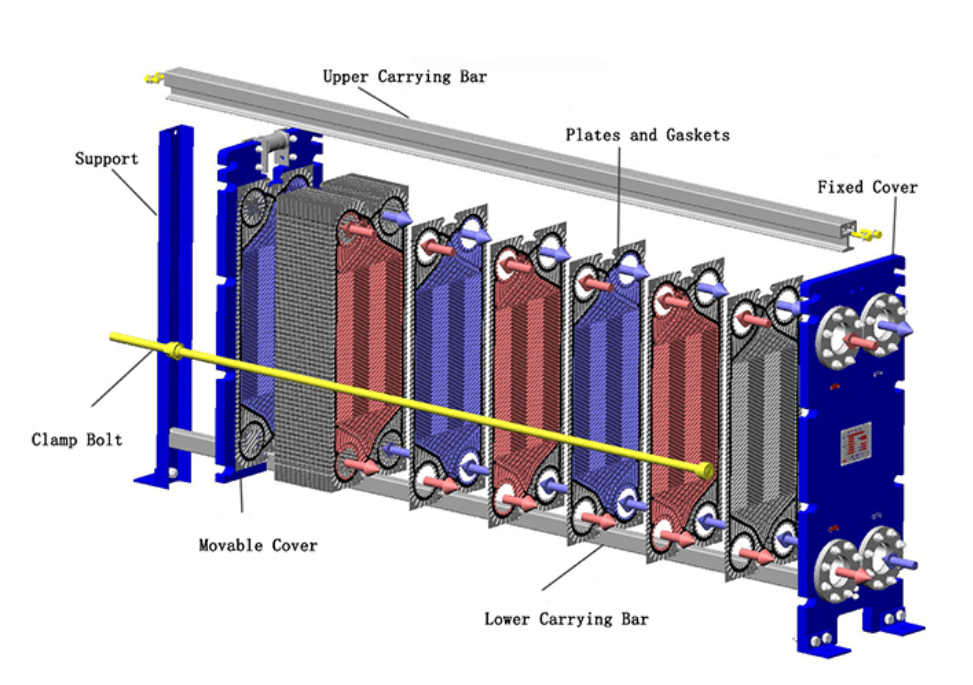

Compact and Modular Designs

Space constraints drive the need for compact and modular heat exchanger designs. Modern units use innovative layouts to fit into tight spaces without sacrificing performance. Modular systems allow companies to scale capacity up or down as needed.

Key features of compact and modular designs include:

·Smaller footprint for easy installation in crowded facilities

·Lightweight construction for easier handling and transport

·Interchangeable modules for quick upgrades or repairs

Engineers appreciate the flexibility these designs offer. They can add or remove modules to match changing process requirements. This adaptability helps companies respond quickly to new challenges.

Lightweight Composites

Engineers now turn to lightweight composites to improve heat exchanger performance. These materials combine strength with reduced weight. They often use carbon fiber, fiberglass, or advanced polymers. Lightweight composites help companies lower shipping costs and simplify installation.

·Carbon fiber composites resist corrosion and handle high temperatures.

·Fiberglass composites offer good thermal insulation.

·Polymer-based composites provide flexibility and durability.

A lighter heat exchanger means easier handling for workers. It also reduces the load on supporting structures. Many industries, such as aerospace and automotive, benefit from these materials. They need equipment that performs well without adding extra weight.

Lightweight composites can extend the service life of heat exchangers in harsh environments. They resist rust and chemical attack better than many metals.

Designers often find more options in the latest heat exchanger catalogue. They can select composite models that match their project needs.

Additive Manufacturing and 3D Printing

Additive manufacturing, also known as 3D printing, changes how companies design and build heat exchangers. This technology allows engineers to create complex shapes that traditional methods cannot produce. They can optimize internal channels for better heat transfer.

·3D printing reduces material waste.

·Engineers can prototype new designs quickly.

·Customization becomes easier and more affordable.

A table below shows some advantages of additive manufacturing:

| Benefit | Impact on Heat Exchangers |

|---|---|

| Complex geometries | Improved efficiency |

| Rapid prototyping | Faster development cycles |

| On-demand production | Lower inventory requirements |

Many manufacturers now use 3D printing to produce small batches or custom units. They can respond to unique customer requests without long lead times. This approach supports innovation and helps companies stay competitive.

Microchannel and Nano Heat Exchangers

Microchannel and nano heat exchangers represent the next step in thermal management. These devices use very small channels to move fluids. The small size increases the surface area for heat transfer. As a result, they deliver higher efficiency in a compact package.

·Microchannel designs work well in electronics cooling and HVAC systems.

·Nano-scale exchangers support advanced medical and scientific equipment.

·Both types reduce energy use and improve system performance.

Engineers find these options in modern heat exchanger catalogues. They can select models that fit tight spaces or demanding applications. Microchannel and nano heat exchangers also help companies meet strict environmental standards.

Renewable Energy Integration in Heat Exchanger Catalogue

Solar Thermal Compatibility

Many industries now seek ways to harness solar energy for heating applications. Modern heat exchangers support solar thermal systems by transferring heat from solar collectors to water or other fluids. Engineers can find models in the heat exchanger catalogue that work with both flat-plate and evacuated tube solar collectors. These units often feature materials that resist scaling and corrosion, which helps maintain efficiency over time.

Key features of solar-compatible heat exchangers include:

·High thermal conductivity for rapid heat transfer

·Durable construction for outdoor environments

·Easy integration with existing solar panels

Geothermal Applications

Geothermal energy uses the earth’s natural heat for sustainable heating and cooling. Heat exchangers play a vital role in these systems by moving heat between the ground and building systems. The latest heat exchanger catalogue offers specialized models for geothermal loops, including both open-loop and closed-loop designs.

Engineers select geothermal heat exchangers based on:

·Fluid compatibility (water, glycol, or refrigerant)

·Resistance to soil minerals and underground conditions

·Compact size for easy installation

A table below highlights common geothermal heat exchanger types:

| Type | Application | Benefit |

|---|---|---|

| Coaxial | Closed-loop | High efficiency |

| Plate | Open-loop | Easy maintenance |

| Shell & Tube | Hybrid systems | Versatile performance |

Waste Heat Recovery Solutions

Waste heat recovery captures excess heat from industrial processes and reuses it for other operations. This approach improves energy efficiency and reduces emissions. Many companies now look for heat exchangers designed specifically for waste heat recovery in the heat exchanger catalogue.

Engineers benefit from:

·Customizable designs for different waste heat sources

·High-temperature materials for demanding environments

·Modular systems for easy expansion

AI and Data Analytics in Heat Exchanger Catalogue

Artificial intelligence and data analytics now play a crucial role in the evolution of the heat exchanger catalogue. These technologies help engineers make smarter decisions, improve equipment reliability, and boost system performance.

Predictive Maintenance Tools

Predictive maintenance tools use AI to monitor heat exchanger health. Sensors collect data on temperature, pressure, and flow. The system analyzes this information to detect early signs of wear or failure. Maintenance teams receive alerts before problems cause downtime.

·Reduces unexpected breakdowns

·Extends equipment lifespan

·Lowers maintenance costs

Automated Sizing and Selection

Automated sizing and selection tools use data analytics to match the right heat exchanger to each application. Engineers enter process details, such as fluid type and operating conditions. The system reviews thousands of options in seconds.

A comparison table highlights the benefits:

| Feature | Traditional Method | Automated Tool |

|---|---|---|

| Speed | Slow | Fast |

| Accuracy | Variable | High |

| Human Error | Possible | Minimal |

These tools save time and reduce mistakes. Engineers can trust the results and focus on other project tasks.

Performance Optimization Algorithms

Performance optimization algorithms use real-time data to fine-tune heat exchanger operation. The system adjusts settings to maximize efficiency and minimize energy use. Engineers see instant feedback and can make changes as needed.

·Improves energy savings

·Increases process reliability

·Supports sustainability goals

Industry-Specific Adaptability in Heat Exchanger Catalogue

Custom Solutions for HVAC

Engineers in the HVAC industry require heat exchangers that deliver reliable temperature control and energy efficiency. Manufacturers design custom solutions to meet the unique demands of commercial buildings, hospitals, and schools. These solutions often include compact units, noise reduction features, and easy maintenance access.

·Variable flow designs help regulate indoor climates.

·Antimicrobial coatings support healthy air quality.

·Modular components allow quick upgrades.

A table below highlights common HVAC requirements and matching features:

| HVAC Need | Heat Exchanger Feature |

|---|---|

| Quiet operation | Sound-dampening materials |

| Space constraints | Slim, modular designs |

| Air quality | Antimicrobial surfaces |

Innovations for Chemical Processing

Chemical processing plants face harsh operating conditions. They need heat exchangers that resist corrosion and handle aggressive fluids. Manufacturers respond by offering specialized alloys and advanced coatings. Engineers select units with precise temperature control and high-pressure tolerance.

·Titanium and Hastelloy alloys withstand corrosive chemicals.

·Double-wall designs prevent cross-contamination.

·Automated cleaning systems reduce downtime.

Innovations in this sector improve plant safety and process reliability. Engineers can choose from a wide range of configurations to match specific chemical reactions.

Adaptations for Food and Beverage Industry

Food and beverage manufacturers demand heat exchangers that meet strict hygiene standards. Companies design units with smooth surfaces and easy-to-clean components. Stainless steel remains the preferred material due to its durability and resistance to contamination.

·Sanitary connections prevent bacterial growth.

·Quick-disassembly features support regular cleaning.

·Low-pressure drop designs protect delicate ingredients.

A checklist for food industry heat exchangers includes:

·✅ FDA-approved materials

·✅ CIP (Clean-In-Place) compatibility

·✅ Leak-proof seals

Sustainability and Environmental Impact in Heat Exchanger Catalogue

Energy-Saving Features

Manufacturers now design heat exchangers with energy-saving features that help companies reduce power consumption. These features include advanced fin designs, optimized flow paths, and high-efficiency surfaces. Engineers select models that minimize heat loss and maximize transfer rates. Many units use variable speed pumps and smart controls to adjust performance based on demand.

A table below highlights common energy-saving features and their benefits:

| Feature | Benefit |

|---|---|

| Optimized fins | Improved heat transfer |

| Variable speed pumps | Lower energy use |

| Smart controls | Adaptive performance |

Eco-Friendly Manufacturing Processes

Companies now prioritize eco-friendly manufacturing processes when producing heat exchangers. They use recycled materials and reduce waste during fabrication. Many factories implement water-saving techniques and energy-efficient machinery. Some manufacturers choose non-toxic coatings and avoid hazardous chemicals.

·Recycled metals lower environmental impact.

·Water-based paints reduce air pollution.

·Efficient production methods save resources.

Engineers look for certifications that verify sustainable practices. These certifications assure buyers that products meet strict environmental standards.

Lifecycle Assessment Tools

Lifecycle assessment tools help engineers evaluate the total environmental impact of a heat exchanger. These tools analyze raw material sourcing, manufacturing, operation, and end-of-life disposal. Users compare models in the heat exchanger catalogue to find options with the lowest carbon footprint.

Key benefits of lifecycle assessment tools include:

·Clear understanding of long-term sustainability

·Data-driven decision making

·Support for corporate environmental policies

Industry professionals see modern solutions in the heat exchanger catalogue driving new standards for efficiency and sustainability. Smart technologies, advanced materials, and AI-powered analytics help teams make better choices and improve operations.

·Companies adapt quickly to changing demands.

·Engineers reach performance and environmental goals with greater confidence.

These innovations shape the future of thermal management across industries.

FAQ

What advantages do digital heat exchanger catalogues offer over printed versions?

Digital catalogues provide instant updates, interactive tools, and mobile access. Engineers find products faster and compare specifications easily. Companies reduce errors and improve collaboration.

Digital platforms support real-time data and remote access, making selection and analysis more efficient.

How do AI-powered tools improve heat exchanger selection?

AI-powered tools analyze process requirements and recommend optimal models. They minimize human error and speed up decision-making.

·Engineers receive accurate sizing and performance predictions.

·Companies benefit from automated selection and reduced downtime.

Which industries benefit most from advanced heat exchanger materials?

Industries such as chemical processing, food and beverage, and HVAC gain the most.

| Industry | Benefit |

|---|---|

| Chemical | Corrosion resistance |

| Food & Beverage | Hygiene and durability |

| HVAC | Energy efficiency |

Can engineers customize heat exchangers for unique applications?

Engineers use interactive configurators to adjust dimensions, materials, and connections.

Customization ensures compatibility with specific systems and process requirements.

Companies achieve better performance and meet industry standards with tailored solutions.