Printed Circuit Heat Exchanger Powers Up The Future Of Clean Energy

Printed circuit heat exchangers save space and boost energy efficiency, making energy systems cleaner and more compact. They reduce material use and waste, lowering costs and environmental impact through smart design and recycling.

Sustainability Advantages of PCHE

Enhanced Energy Efficiency

You gain a significant boost in energy efficiency when you choose a printed circuit heat exchanger. These devices use advanced microchannel designs that maximize heat transfer while minimizing energy loss. Recent studies show that PCHEs with zigzag flow channels can increase heat transfer effectiveness by up to 90% compared to straight or serpentine channels. This improvement comes with a manageable increase in pressure drop, making the technology suitable for high-performance applications like waste heat recovery and advanced power cycles.

Wide application of SHPHE’s Printed Circuit Heat Exchanger

In large-scale tests, compact welded plate heat exchangers delivered reliable heat exchange at a wide range of pressures and temperatures, with strong correlations between predicted and measured performance. These results demonstrate that you can rely on printed circuit heat exchangers for consistent, high-efficiency operation in demanding environments.

Reduced Material Usage and Waste

You benefit from reduced material usage and waste when implement a printed circuit Compact Heat Exchanger. The compact, lightweight design uses less raw material than traditional heat exchangers. This efficiency not only saves resources but also lowers manufacturing costs. Life cycle assessment data from related industries show that recycling integrated circuits and using recyclable substrates can cut the environmental footprint by over 50%. These practices reduce carbon emissions and resource consumption, making PCHE manufacturing more sustainable.

· PCHE use fewer metals and less energy during production.

· Generate less waste, thanks to optimized manufacturing processes.

The design flexibility of printed circuit heat exchangers allows you to tailor each unit to specific applications, reducing excess material and waste even further.

Lower Carbon Footprint

Adopting printed circuit heat exchangers in energy systems help lower the carbon footprint. Their high thermal efficiency means you need less energy to achieve the same level of heat transfer, which directly reduces greenhouse gas emissions.

As a result, industries across Europe and other regions are turning to PCHEs to meet ambitious climate targets.

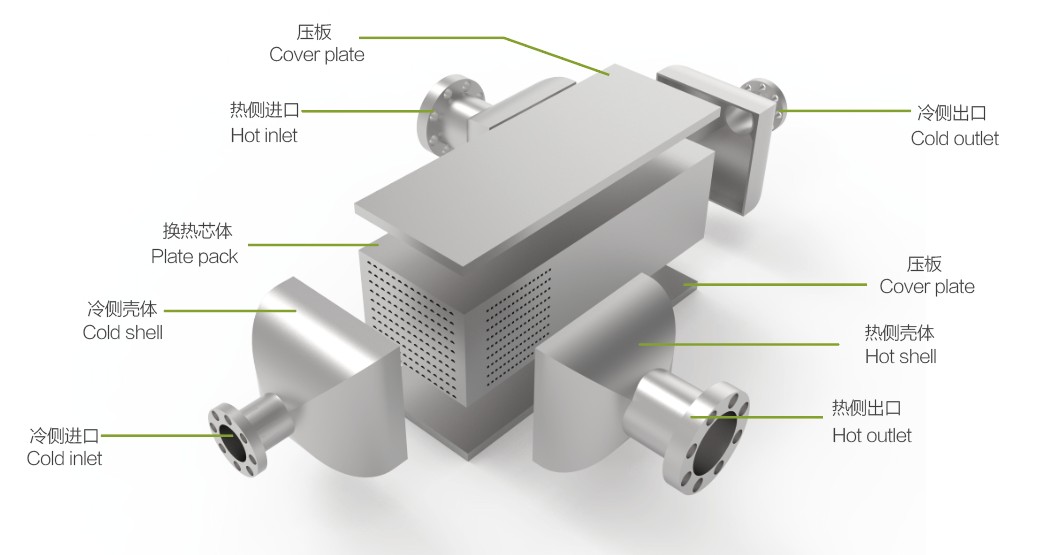

Structure of SHPHE’s Printed Circuit Heat Exchanger

Aspect | Printed Circuit Heat Exchangers (PCHEs) | Traditional Heat Exchangers |

Heat Transfer Efficiency | High; can be improved by ~23% through optimization | Lower; affected by axial heat conduction losses |

Pressure Drop | Low overall; optimized designs increase effectiveness | Generally higher due to less compact design |

Compactness | Very compact, microchannel design | Larger footprint, less suitable for tight spaces |

Application Suitability | Nuclear, aerospace, waste heat recovery | General use, less efficient in compact systems |

This table shows that you achieve higher efficiency and lower emissions with a printed circuit heat exchanger, making it a smart choice for sustainable operations.

SHPHE’s Mission in Sustainable Development

Through continuous technological innovation, SHPHE aims to lead the industry forward, working alongside top companies both in China and internationally. The goal is to become a premier system integrator, delivering high-quality, energy-efficient solutions that are “nationally leading and globally top-tier.”

At the same heat exchange capacity, SHPHE’s removable plate heat exchangers are designed to use the least amount of energy. From research and development to design, simulation, and precision manufacturing, we ensure optimal product performance. SHPHE offers over 10 series of top-tier energy-efficient products, including models with over 350 corner holes at the highest efficiency level. Compared to 3rd-level energy-efficient plate heat exchangers, our E45 model, processing 2000m³/h, can save approximately 22 tons of standard coal annually and reduce CO2 emissions by around 60 tons.

Printed circuit heat exchanger in Clean Energy Applications

Renewable Energy Systems

You can transform renewable energy systems by adopting a printed circuit heat exchanger. These devices deliver superior heat transfer, pressure resistance, and compactness, making them ideal for solar, wind, and biomass applications. Field studies show that you achieve a 61.3% improvement in economic sustainability and a 33% boost in environmental sustainability when you use PCHEs. In a biomass-powered multi-generation plant, you can produce electricity, heating, cooling, hydrogen, and freshwater more efficiently. Optimization methods like Response Surface Methodology help you fine-tune performance, while advanced modeling ensures reliable operation in supercritical CO2 cycles.

· Achieve up to 30% higher thermal efficiency compared to conventional exchangers

· Reduce system size and weight by up to 85%

· Operate reliably under extreme pressures and temperatures

Industrial Decarbonization

By integrating printed circuit heat exchangers into power cycles and process systems, you can increase energy efficiency from 36.91% to 41.22% and exergy efficiency from 60.58% to 66.91% in combined supercritical CO2 and Organic Rankine cycles. These improvements lower fuel consumption and emissions, supporting your sustainability goals.

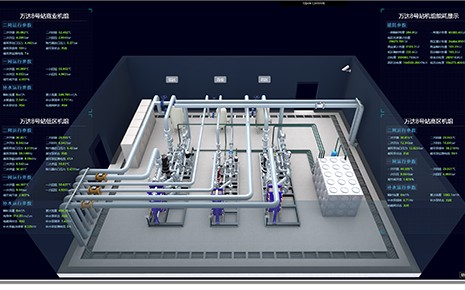

Smart heating system by shphe

PCHEs support hydrogen production, carbon capture, and energy storage across Europe, North America, and Asia-Pacific, as shown in industry trend tables.

Integration with Emerging Technologies

We strongly recommend using printed circuit heat exchangers in advanced nuclear reactors, hydrogen refueling stations, and LNG systems. Their microchannel design and robust construction allow you to handle high pressures and temperatures, making them essential for supercritical CO2 power cycles and compact energy storage. Empirical studies confirm their critical role in improving efficiency and reducing the footprint of next-generation clean energy systems.

FAQ

What makes a printed circuit heat exchanger different from a traditional heat exchanger?

You get a compact, lightweight design with higher heat transfer efficiency. PCHEs use microchannels, which allow you to save space and improve performance.

Can you use printed circuit heat exchangers in high-pressure or high-temperature systems?

Yes. You can rely on PCHEs for extreme conditions. Their robust construction and advanced materials handle high pressures and temperatures with ease.

How do printed circuit heat exchangers support clean energy goals?

You reduce emissions and energy waste. PCHEs help you achieve higher efficiency and lower your carbon footprint in renewable and industrial applications.

If you need further consultation and discussion, please feel free to contact us.

Email: info@shphe.com

WhatsApp /Cell: +86 15201818405