Gasketed Plate Heat Exchangers Transforming Industrial Efficiency

Gasketed plate heat exchangers boost industrial ef...

More

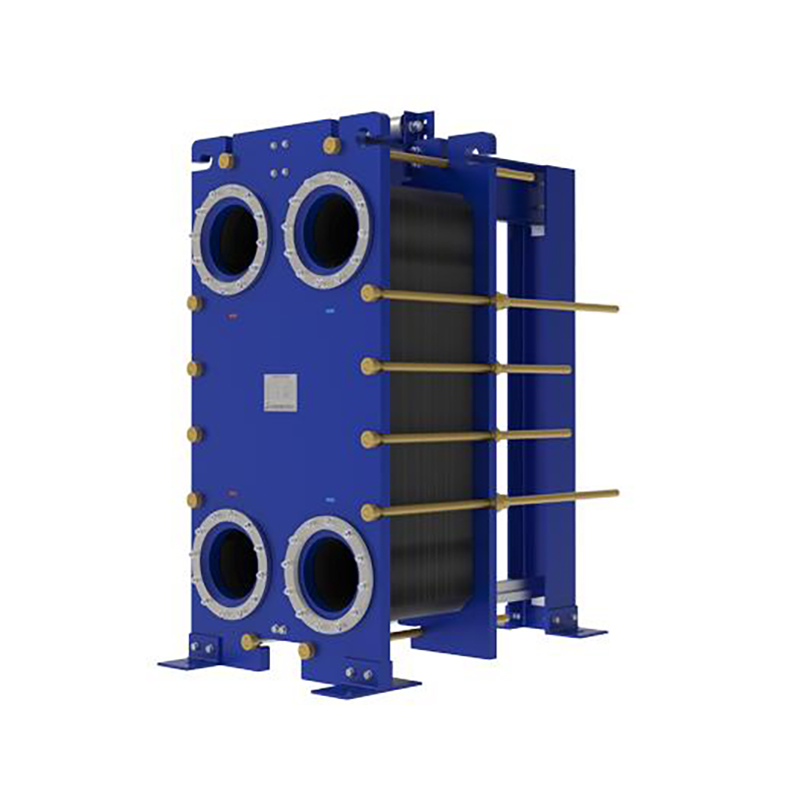

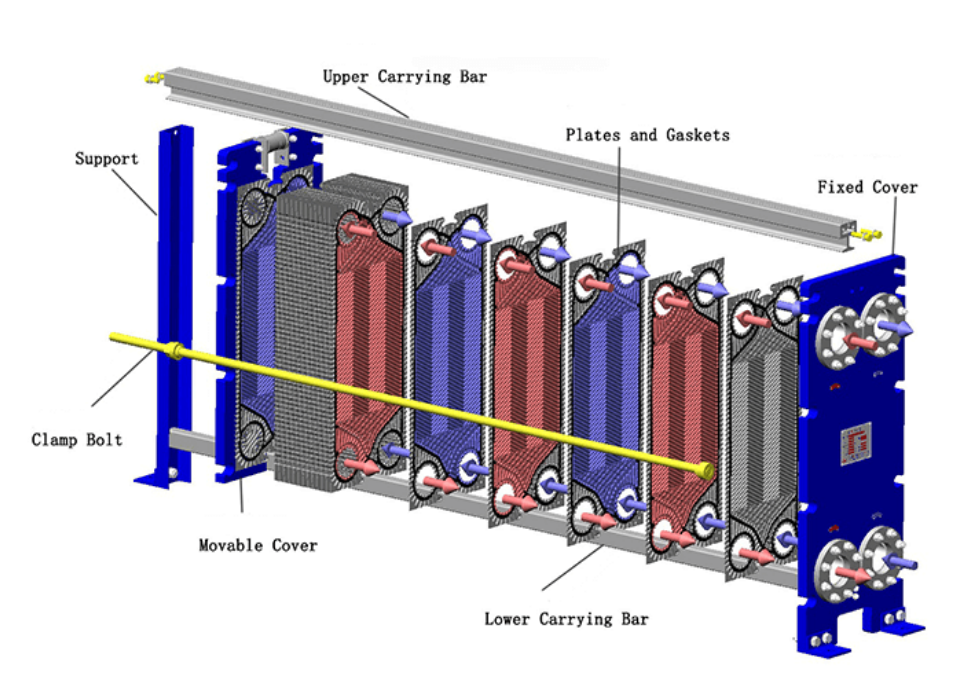

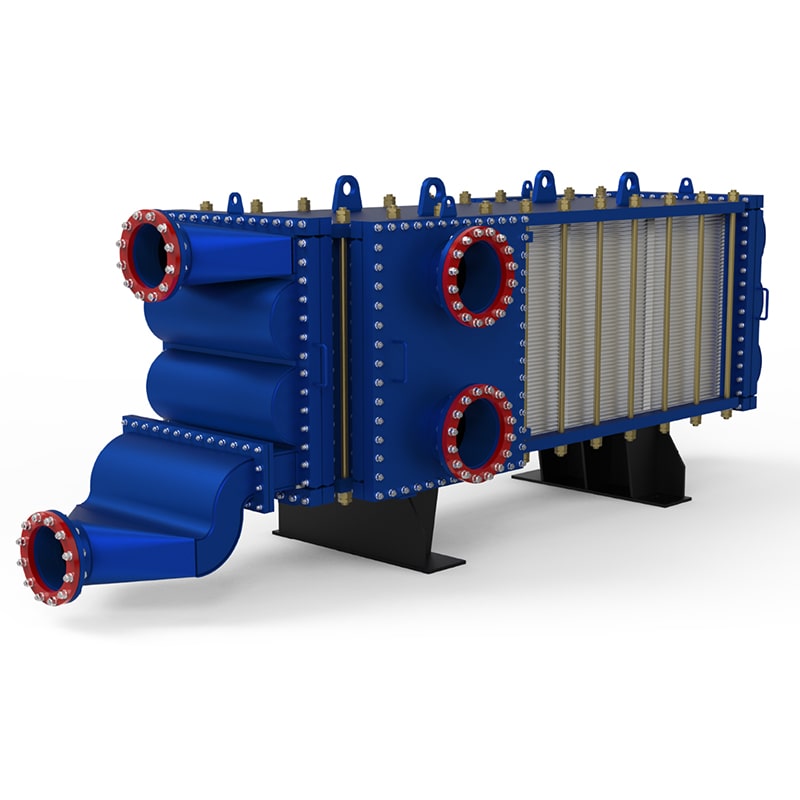

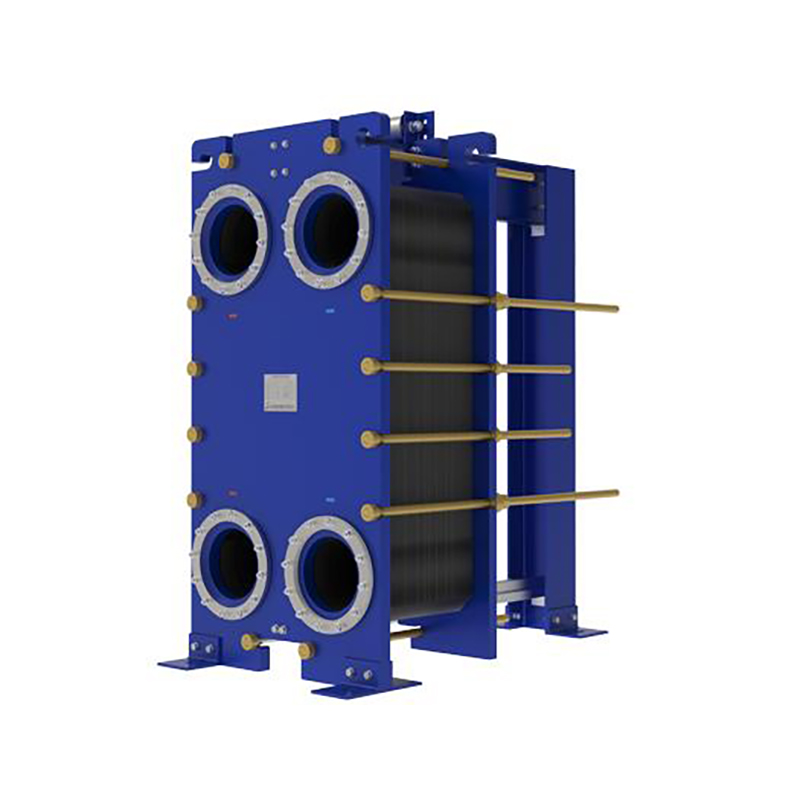

A PHE (Plate Heat Exchanger) condenser is a compact, high-efficiency heat exchange device designed to transfer thermal energy between fluids in industrial processes. Unlike traditional shell-and-tube condensers, PHE condensers utilize a series of corrugated metal plates to maximize surface area and turbulence, enhancing heat transfer rates. These systems are widely used in refrigeration, chemical processing, power plants, and HVAC applications due to their modular design, scalability, and superior thermal performance.

PHE condensers operate by channeling hot and cold fluids through alternating plate channels, separated by thin gaskets or welded seams. The corrugated plate design creates intense turbulence, reducing fouling and improving energy efficiency by up to 90% compared to conventional systems. Key components include stainless steel or titanium plates, nitrile or EPDM gaskets, and precision-engineered frames. Leading manufacturers like Alfa Laval, SWEP, and Danfoss offer PHE condensers with capacities ranging from 5 kW to 50 MW, catering to diverse industrial demands. Their compact footprint (up to 80% smaller than shell-and-tube units) and lightweight construction make them ideal for space-constrained installations.

PHE condensers outperform traditional heat exchangers in energy efficiency, maintenance costs, and operational flexibility. Industry data shows they reduce energy consumption by 30–50% due to optimized heat transfer coefficients (3,000–7,000 W/m²K vs. 500–1,500 W/m²K in shell-and-tube models). Their modular design allows easy capacity expansion by adding or removing plates, avoiding costly system replacements.

Real-world applications demonstrate their reliability: in food processing, PHE condensers maintain precise temperature control with ΔT as low as 1°C, minimizing product degradation. Chemical plants report 40% lower maintenance costs thanks to accessible plate cleaning and gasket replacement. Google search trends reveal a 120% YoY increase in queries for "PHE condenser retrofit," reflecting growing adoption. Environmental benefits include 20–30% lower refrigerant charges and compliance with EPA/F-Gas regulations. With lifespans exceeding 15 years and ROI periods under 3 years, PHE condensers are a proven investment for sustainable industrial cooling.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Gasketed plate heat exchangers boost industrial ef...

More

Plate heat exchangers cut industrial energy use, l...

More

Plate heat exchangers boost industrial energy effi...

More

A gasket free heat exchanger uses welded plates fo...

More

A heat exchanger plate is vital for industrial eff...

More

A gasketed plate and frame heat exchanger improves...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe PHE condenser is incredibly efficient and has significantly improved our cooling system's performance. Highly recommended!

Emily Johnson

Process TechnicianGreat product! The PHE condenser is compact yet powerful, perfect for our industrial applications. Minor improvements in durability would make it perfect.

Michael Brown

Facility ManagerThis PHE condenser exceeded our expectations. Easy to install and maintain, with excellent heat transfer efficiency. A game-changer for our facility.

Sarah Davis

Research ScientistThe PHE condenser works flawlessly in our lab setup. It's reliable and energy-efficient, though a bit pricey. Still worth the investment.