How to Choose the Right OEM Pillow Plate Supplier for Your Project

Choosing a supplier without these qualities can le...

More

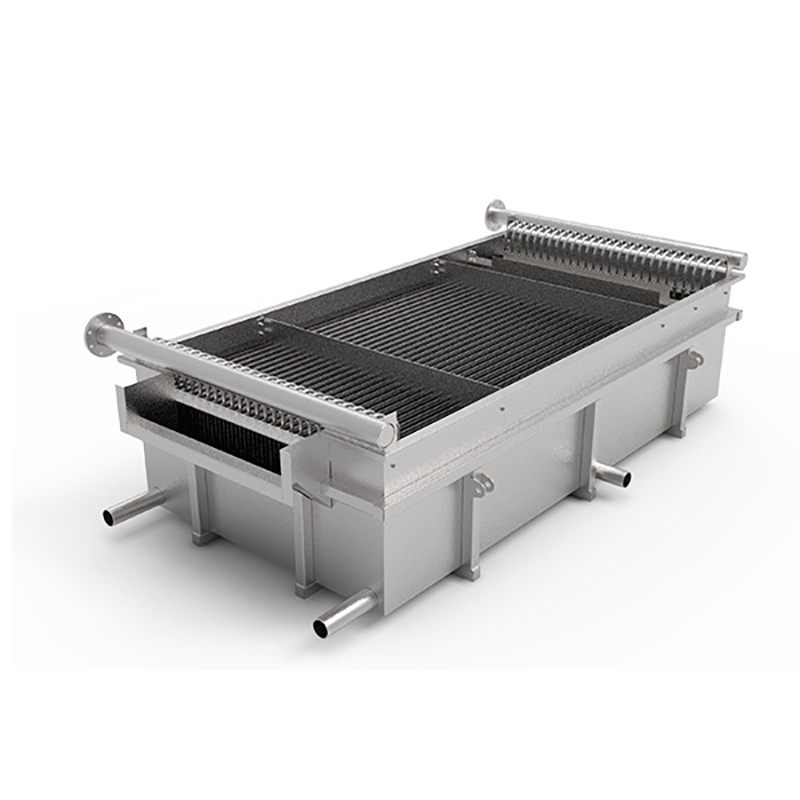

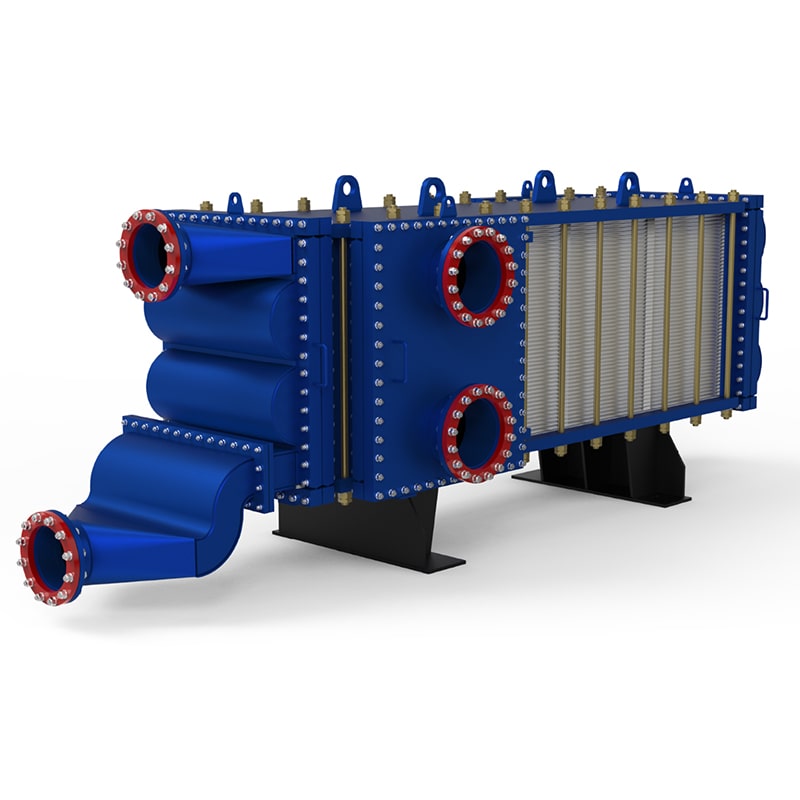

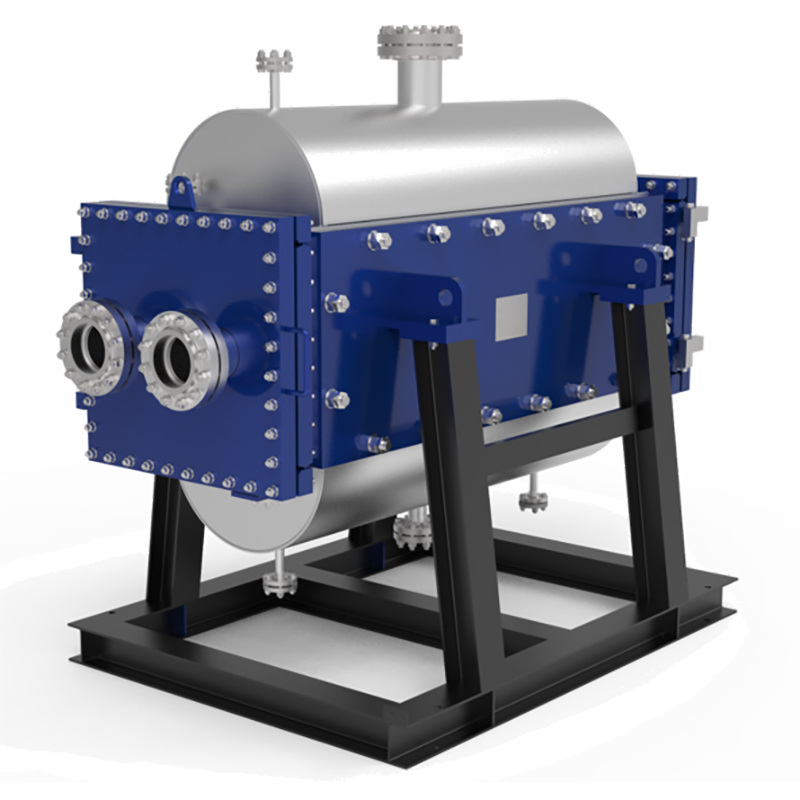

A PHE (Plate Heat Exchanger) Water Chiller is an advanced industrial cooling system designed to regulate temperatures in large-scale operations with precision and energy efficiency. Unlike traditional chillers, PHE models utilize compact plate heat exchangers to maximize heat transfer while minimizing energy consumption. These systems are widely used in manufacturing, data centers, food processing, and HVAC applications, offering superior thermal performance and scalability.

PHE Water Chillers stand out for their modular design, which allows for easy maintenance and customization. The plate heat exchanger technology ensures rapid cooling by creating a large surface area for heat dissipation, reducing operational costs by up to 30% compared to conventional shell-and-tube chillers. With a focus on sustainability, modern PHE chillers often integrate eco-friendly refrigerants and smart controls to optimize performance. Industries relying on consistent temperature control, such as pharmaceuticals or plastics molding, benefit from their reliability and compliance with stringent environmental regulations.

Selecting a PHE Water Chiller ensures long-term cost savings, operational efficiency, and environmental compliance. These systems are engineered to handle high-capacity cooling demands while maintaining minimal energy usage, making them ideal for facilities prioritizing sustainability. Real-world data shows that PHE chillers can reduce energy consumption by 20-40% compared to older models, directly lowering utility expenses. Their compact footprint also saves valuable floor space, a critical advantage for urban industrial setups.

Beyond efficiency, PHE chillers offer unmatched durability and low maintenance requirements. The corrosion-resistant plates and gaskets extend the system’s lifespan, while automated diagnostics reduce downtime. Leading manufacturers like Alfa Laval and SWEP report that PHE chillers maintain 95%+ thermal efficiency even after years of operation. For industries facing strict carbon regulations, these chillers support compliance with standards like ISO 14001 and LEED certification. Investing in a PHE Water Chiller translates to scalable, future-proof cooling that aligns with global green initiatives.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Choosing a supplier without these qualities can le...

More

Compare spiral, shell-and-tube, and plate slurry h...

More

Gas to gas plate heat exchangers transfer heat usi...

More

A plate heat exchanger (PHE) is a device engineere...

More

A heat exchanger plate is a core component that tr...

More

What the carrying bar does in a PHE—support, align...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Emily Johnson

Laboratory TechnicianThe PHE water chiller has been a game-changer for our lab! It maintains precise temperatures effortlessly, and the energy efficiency is impressive.

Michael Chen

HVAC EngineerGreat performance and reliability. The PHE water chiller integrates seamlessly with our systems, though installation could be slightly more straightforward.

Sarah Williams

Production ManagerOutstanding durability and cooling capacity. This chiller has significantly reduced downtime in our manufacturing process. Highly recommend!

David Rodriguez

Facility SupervisorThe PHE water chiller is quiet and efficient, perfect for our hospital's cooling needs. Minor improvements in user interface would make it flawless.