Products

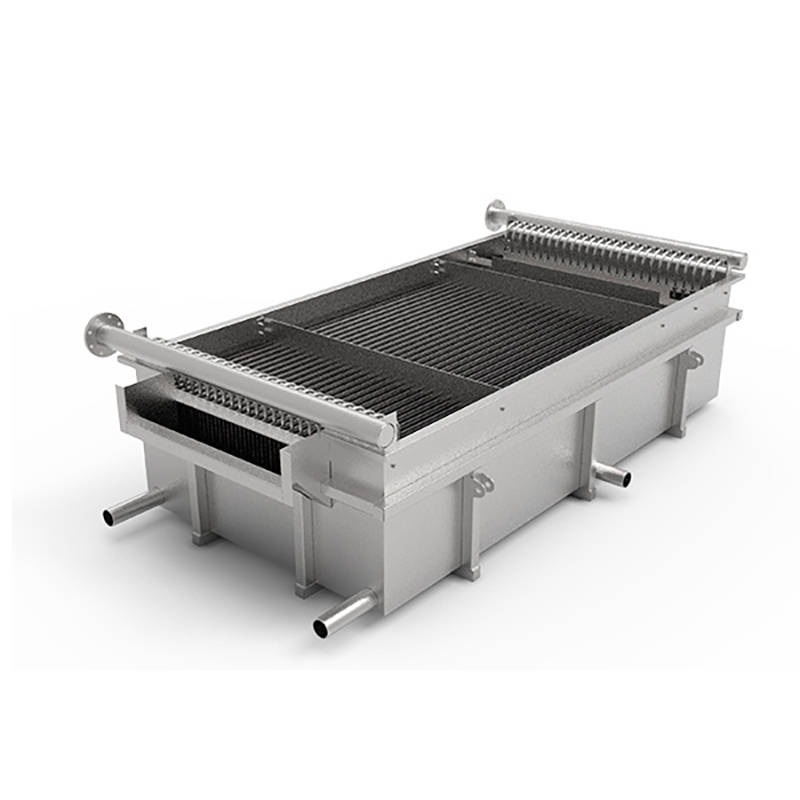

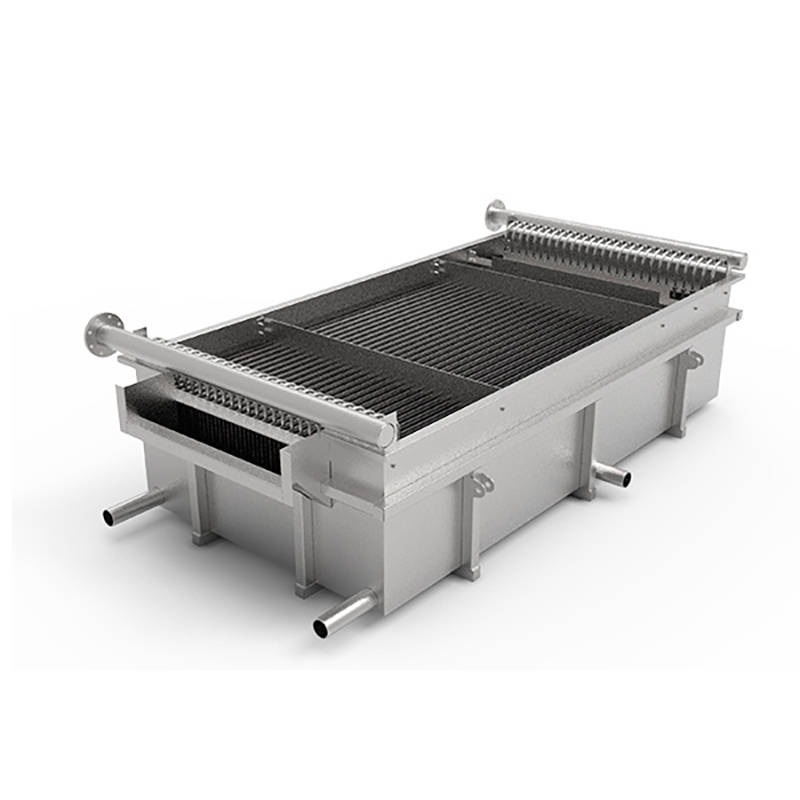

Pillow Plate

Certificates: ASME, NB, CE, BV, SGS etc.

Pillow Plate, also known as a dimple plate or embossed plate, originated in the mid-20th century as industries sought more efficient heat exchange and lightweight structural materials. Traditional flat plates had limitations in thermal efficiency and mechanical strength, while the Pillow Plate's unique design addressed these issues by incorporating internal cavities. Over time, advancements in manufacturing technologies have further optimized its materials, production processes, and application scope.

The Pillow Plate's adaptability, coupled with its ability to optimize processes and reduce operational costs, has cemented its role as a transformative technology in modern industrial applications. Its continued evolution and integration into cutting-edge solutions underscore its importance in driving innovation and efficiency across global industries.

In search of expert advice? Our experienced engineers stand ready to assist you. Discover more about our heat exchangers and compl-ementary services, all designed to precisely align with your needs.

contact us

Product Details

-

Principle of Pillow Plate

The core principle of the Pillow Plate lies in its internal cavity structure. The plate is formed by welding or stamping to create enclosed cavities, which can be filled with fluids (such as water, oil, or gas) to facilitate efficient heat exchange. The cavity structure also enhances the plate's mechanical strength, allowing it to withstand higher pressures and loads. During operation, the fluid flows through the cavities, exchanging heat with the external environment through the plate's surface, enabling cooling, heating, or insulation functions. -

Widely Used in Modern Industrial Applications

Pillow Plate, with its innovative design and multifaceted advantages, has emerged as a cornerstone in modern industrial applications, revolutionizing industries that demand efficient heat exchange, structural integrity, and lightweight solutions. Its unique cavity-based structure not only enhances thermal performance but also provides exceptional mechanical strength, making it a versatile and indispensable material across diverse sectors.

Product Advantage

-

High Thermal Efficiency

The large surface area and internal cavity structure enhance heat transfer, making them ideal for applications requiring efficient cooling or heating.Lightweight Design

The cavity structure reduces material usage while maintaining strength, resulting in a lightweight yet durable solution. -

Mechanical Strength

The design provides excellent resistance to pressure and deformation, ensuring reliability in demanding environments.Versatility

Suitable for various fluids (liquids, gases) and operating conditions, making them adaptable to diverse industrial applications. -

Hygienic Properties

Smooth surfaces and easy cleaning make them ideal for industries like food and pharmaceuticals, where cleanliness is critical.Cost-Effectiveness

Reduced material consumption and improved efficiency lower operational and manufacturing costs, offering long-term economic benefits.

Product Parameters

| Parameter Item | Parameter |

|---|---|

| Max. Area Each Plate | 24㎡ |

| Plate Thickness | 0.8 – 4mm |

| Design Temperature | -20 ~ 300℃ |

| Max. Design Pressure | 63 Bar |

| Plate material | 304, 316L, 2205, 904L, ST13, C-276, Titanium etc, |

How to design and manufacture

Pillow plate

Define Requirements

- Purpose: Determine the application (e.g., heat exchangers, tanks, or structural components).

- Dimensions: Specify length, width, and thickness based on the intended use.

- Performance Criteria: Define parameters like pressure tolerance, thermal efficiency, and load-bearing capacity.

Structural Design

- Shape and Pattern: Design the pillow-like structure with raised and recessed areas to enhance strength and heat transfer efficiency.

- Internal Channels: Plan the internal flow paths for fluids or gases, ensuring uniform distribution and minimal pressure drop.

Material Selection

- Base Material: Choose materials like stainless steel, aluminum, or carbon steel, considering factors such as corrosion resistance, strength, and thermal conductivity.

- Surface Finish: Decide on surface treatments (e.g., polished, brushed, or coated) based on the application environment.

Welding and Assembly

- Seam Welding: Weld the edges of the pillow plate to ensure structural integrity and leak-proof performance.

- Assembly: Integrate the pillow plate into larger systems (e.g., heat exchangers or tanks) using welding or bolting techniques.

Applications of Pillow Plate

Pillow Plate's innovative design, combined with its numerous advantages, has made it used in modern industrial applications.

-

Heat Exchange Solutions for Environmental Protection IndustryEnvironmental Protection industry focuses on reducing pollution, conserving resources, and promoting sustainable development. Its importance lies in addressing climate change, protecting ecosystems, and ensuring public health. The primary goal is to achieve "zero emissions" by minimizing waste and transitioning to renewable energy. This is achieved through advanced technologies, waste recycling, and energy-efficient systems. Plate heat exchangers (PHEs) play a crucial role by enhancing energy efficiency in industrial processes, reducing energy consumption, and enabling heat recovery. Their compact design and high heat transfer efficiency support sustainable practices, making them essential in achieving emission reduction targets and fostering a greener future.

Heat Exchange Solutions for Environmental Protection IndustryEnvironmental Protection industry focuses on reducing pollution, conserving resources, and promoting sustainable development. Its importance lies in addressing climate change, protecting ecosystems, and ensuring public health. The primary goal is to achieve "zero emissions" by minimizing waste and transitioning to renewable energy. This is achieved through advanced technologies, waste recycling, and energy-efficient systems. Plate heat exchangers (PHEs) play a crucial role by enhancing energy efficiency in industrial processes, reducing energy consumption, and enabling heat recovery. Their compact design and high heat transfer efficiency support sustainable practices, making them essential in achieving emission reduction targets and fostering a greener future. -

Heat Exchange Solutions for Food IndustryFood industry encompasses production, processing, packaging, and distribution of consumables, prioritizing safety, efficiency, and sustainability. Key sectors include dairy, beverages, canned goods, and prepared foods. Plate heat exchangers (PHEs) play a vital role in thermal processes such as pasteurization, heating, cooling, and concentration. Their compact design, high heat transfer efficiency, and hygienic surfaces ensure rapid temperature control while minimizing energy waste. PHEs also reduce cross-contamination risks and support heat recovery systems, aligning with industry demands for cost-effectiveness and eco-friendly practices. Applications span milk sterilization, juice processing, and waste heat reuse, enhancing productivity and compliance with stringent food safety standards.

Heat Exchange Solutions for Food IndustryFood industry encompasses production, processing, packaging, and distribution of consumables, prioritizing safety, efficiency, and sustainability. Key sectors include dairy, beverages, canned goods, and prepared foods. Plate heat exchangers (PHEs) play a vital role in thermal processes such as pasteurization, heating, cooling, and concentration. Their compact design, high heat transfer efficiency, and hygienic surfaces ensure rapid temperature control while minimizing energy waste. PHEs also reduce cross-contamination risks and support heat recovery systems, aligning with industry demands for cost-effectiveness and eco-friendly practices. Applications span milk sterilization, juice processing, and waste heat reuse, enhancing productivity and compliance with stringent food safety standards. -

Heat Exchange Solutions for Chemical IndustryChemical industry is a highly technical sector, combining specialized design, precision manufacturing, and stringent quality control to meet diverse process demands. Plate heat exchangers are essential in this field, providing efficient heat transfer for heating, cooling, condensation, and evaporation. Their compact design, high thermal efficiency, and adaptability to harsh conditions ensure smooth operations, reduce energy consumption, and support sustainability goals.

Heat Exchange Solutions for Chemical IndustryChemical industry is a highly technical sector, combining specialized design, precision manufacturing, and stringent quality control to meet diverse process demands. Plate heat exchangers are essential in this field, providing efficient heat transfer for heating, cooling, condensation, and evaporation. Their compact design, high thermal efficiency, and adaptability to harsh conditions ensure smooth operations, reduce energy consumption, and support sustainability goals.

Related articles

Read More

To Provide You with Better Service

Honor Our Common Journey,Develop Authentic Alliances,Create Collective Success.

Leave Your Message

* Full Name

* Country/Region

* Email

* Company name

* Telephone Number

* Enter your needs

SHPHE has complete quality assurance system from design, manufacturing, inspection and delivery. It is certified with ISO9001, ISO14001, OHSAS18001 and hold ASME U Certificate.