Comparing welded block and gasketed plate heat exchangers

You can see clear differences between welded block...

More

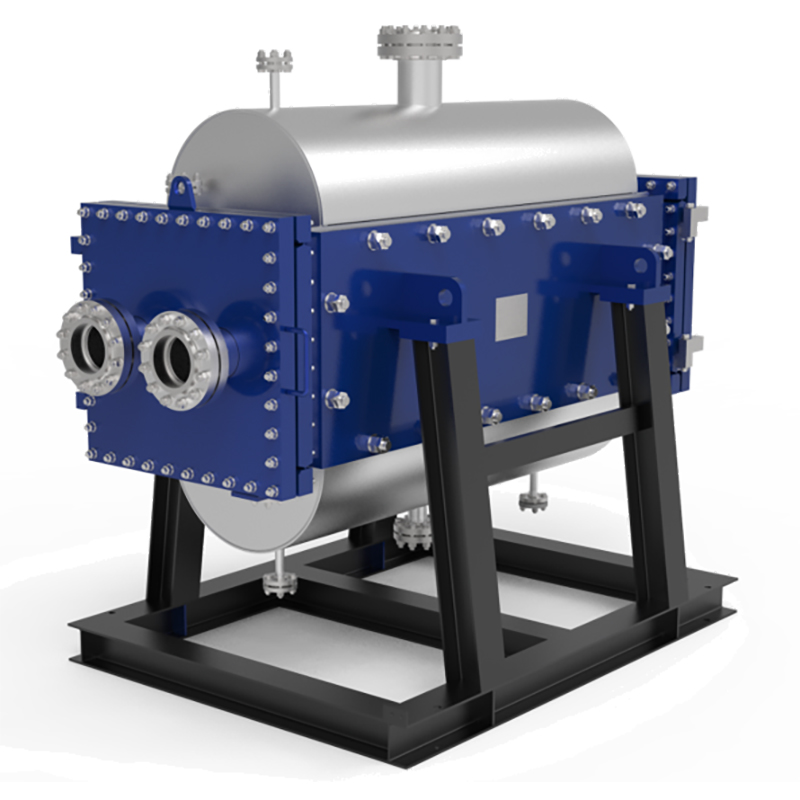

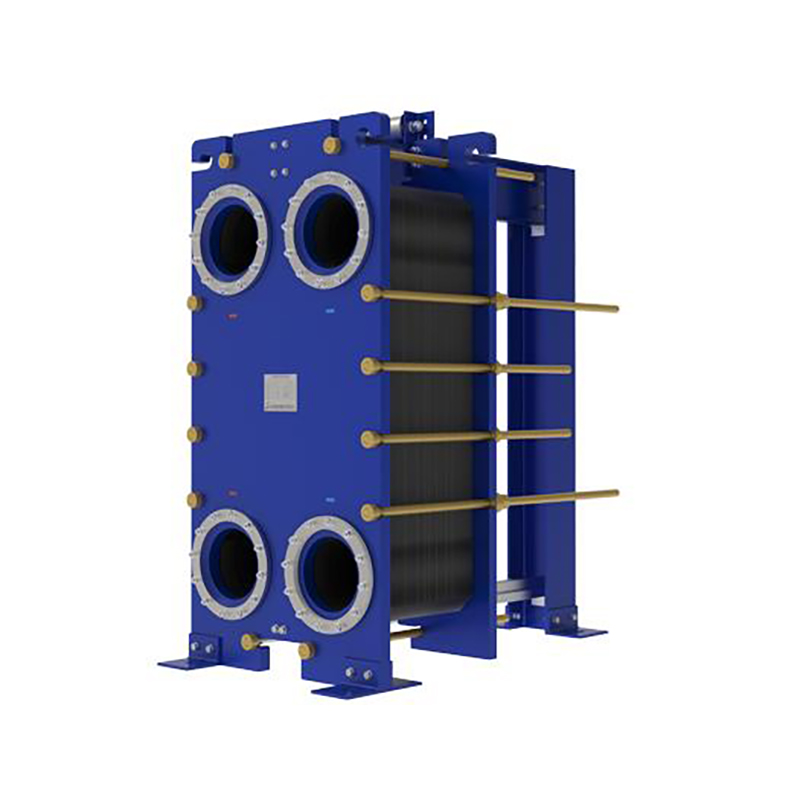

A plate and frame condenser is a compact and efficient heat exchanger designed for condensing vapors into liquids across various industrial processes. It consists of a series of corrugated metal plates clamped together in a frame, creating alternating channels for hot and cold fluids. The design maximizes surface area for heat transfer while minimizing space requirements, making it ideal for applications in refrigeration, chemical processing, power plants, and HVAC systems. Unlike shell-and-tube condensers, plate and frame models offer superior thermal performance due to their turbulent flow patterns and thin plate construction.

Plate and frame condensers are widely used in industries requiring precise temperature control and energy efficiency. Their modular design allows for easy expansion or maintenance by adding or removing plates. Common materials include stainless steel, titanium, and nickel alloys, chosen for corrosion resistance and durability. These condensers handle high-pressure and high-temperature conditions while maintaining low fouling rates. With global demand rising, manufacturers like Alfa Laval, SWEP, and Danfoss dominate the market, offering customized solutions for sectors such as food processing, pharmaceuticals, and oil refineries.

The plate and frame condenser outperforms traditional heat exchangers in multiple ways. Its high heat transfer efficiency reduces energy consumption by up to 30% compared to shell-and-tube models, as confirmed by ASHRAE studies. The compact footprint saves up to 50% space, critical for facilities with spatial constraints. Additionally, the design allows for full drainage, minimizing freezing risks in refrigeration applications. The gasket-sealed plates enable easy disassembly for cleaning or inspection, cutting maintenance downtime by 40% according to industry reports.

Further benefits include scalability—capacity can be adjusted by adding plates without replacing the entire unit. Leak detection is simplified through visible gasket channels, preventing cross-contamination. These condensers also excel in handling viscous fluids and aggressive chemicals due to material versatility. Market data from Grand View Research projects a 6.2% CAGR for plate heat exchangers (including condensers) through 2030, driven by their adoption in renewable energy systems like geothermal and biomass plants. Leading models achieve NTU (Number of Transfer Units) values above 10, ensuring optimal performance in demanding environments.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

You can see clear differences between welded block...

More

The dimple plate heat exchanger, also known as the...

More

Compare steam plate heat exchanger vs shell and tu...

More

Plate heat exchanger gaskets perform 5 key roles: ...

More

Plate and frame heat exchangers offer higher effic...

More

API 662 defines standards for plate heat exchanger...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe plate and frame condenser is incredibly efficient and easy to maintain. It has significantly improved our cooling process.

Emily Johnson

Process TechnicianGreat product! The plate and frame condenser works perfectly for our needs. Installation was straightforward.

Michael Brown

HVAC SpecialistThis condenser is top-notch. It's durable and performs exceptionally well in our HVAC systems.

Sarah Davis

Plant ManagerThe plate and frame condenser has been a reliable addition to our facility. It's energy-efficient and cost-effective.