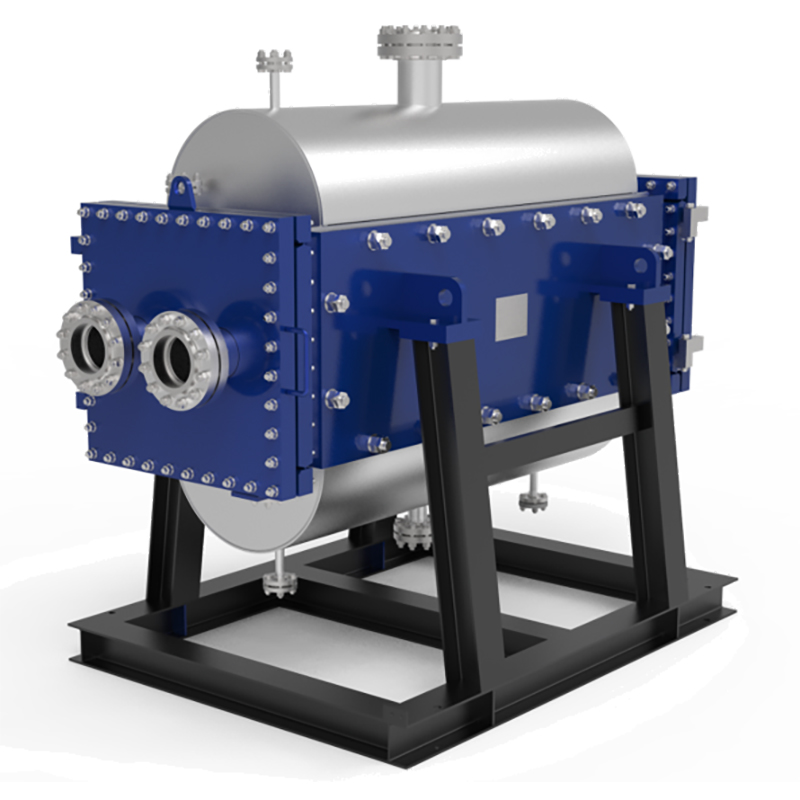

Comparing welded block and gasketed plate heat exchangers

You can see clear differences between welded block...

More

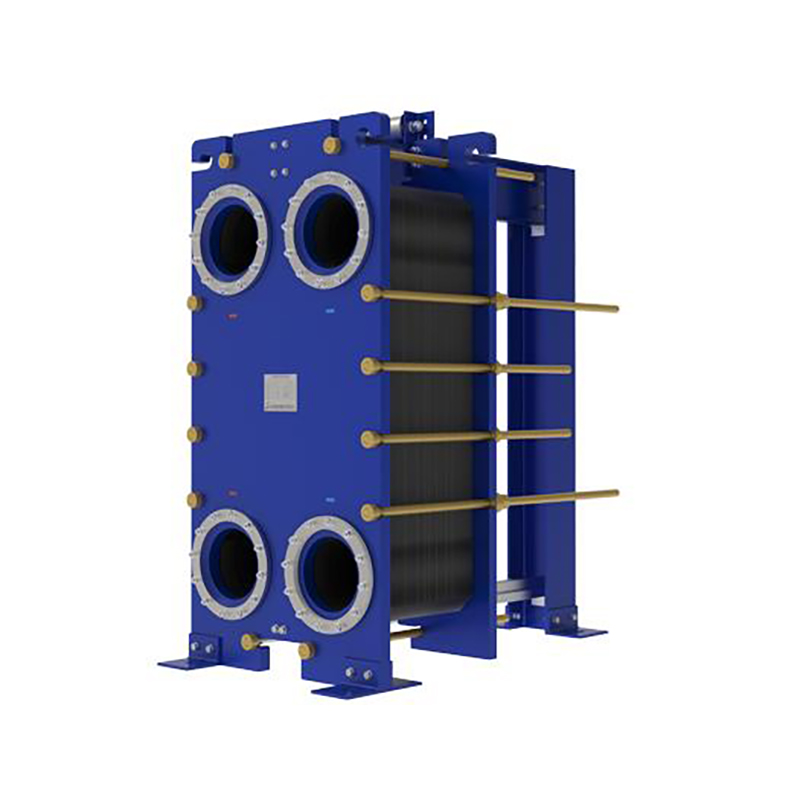

A plate and frame cooler is a highly efficient heat exchanger designed for industrial and commercial applications. It consists of a series of corrugated metal plates clamped together in a frame, creating alternating channels for hot and cold fluids to flow through. The large surface area of the plates facilitates rapid heat transfer, making it ideal for cooling or heating liquids in processes such as HVAC, food and beverage production, chemical processing, and power generation. Plate and frame coolers are compact, modular, and easy to maintain, offering superior thermal performance compared to traditional shell-and-tube heat exchangers.

Plate and frame coolers are widely used due to their adaptability and high efficiency. The design allows for easy expansion or reduction of capacity by adding or removing plates, making them suitable for varying operational demands. The turbulent flow created by the corrugated plates minimizes fouling and ensures consistent performance over time. Common materials include stainless steel, titanium, and other alloys, chosen for their corrosion resistance and durability in harsh environments. Industries such as oil and gas, marine, and manufacturing rely on these coolers for their reliability and energy-saving benefits. With a typical heat transfer efficiency of 90% or higher, plate and frame coolers significantly reduce energy consumption and operational costs.

Plate and frame coolers offer numerous advantages over alternative heat exchange systems. Their compact design saves valuable space, while their modular construction allows for easy customization to meet specific process requirements. The high thermal efficiency reduces energy usage, lowering operational expenses and environmental impact. Additionally, the ability to disassemble and clean individual plates ensures minimal downtime and maintenance costs, a critical factor for industries with continuous production cycles.

Data from industry studies show that plate and frame coolers can achieve up to 50% higher heat transfer rates compared to shell-and-tube models. Their lightweight construction reduces installation costs, and their scalability makes them future-proof for growing operations. Real-world applications in sectors like dairy processing and chemical manufacturing demonstrate their ability to handle high-viscosity fluids and extreme temperatures. With a lifespan exceeding 20 years in well-maintained systems, these coolers provide long-term value. Leading manufacturers like Alfa Laval, SWEP, and GEA report consistent demand due to their proven performance and compliance with global industry standards. Choosing a plate and frame cooler ensures reliability, efficiency, and cost-effectiveness for any heat exchange application.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

You can see clear differences between welded block...

More

The dimple plate heat exchanger, also known as the...

More

Compare steam plate heat exchanger vs shell and tu...

More

Plate heat exchanger gaskets perform 5 key roles: ...

More

Plate and frame heat exchangers offer higher effic...

More

API 662 defines standards for plate heat exchanger...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe plate and frame cooler is incredibly efficient and easy to maintain. It has significantly improved our cooling process.

Emily Johnson

Process TechnicianGreat product! The plate and frame cooler works perfectly for our needs. Installation was straightforward.

Michael Brown

Maintenance SupervisorThis cooler has been a game-changer for our facility. Durable, reliable, and cost-effective.

Sarah Davis

Operations ManagerThe plate and frame cooler performs exceptionally well under high pressure. Highly recommend it for industrial applications.