5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

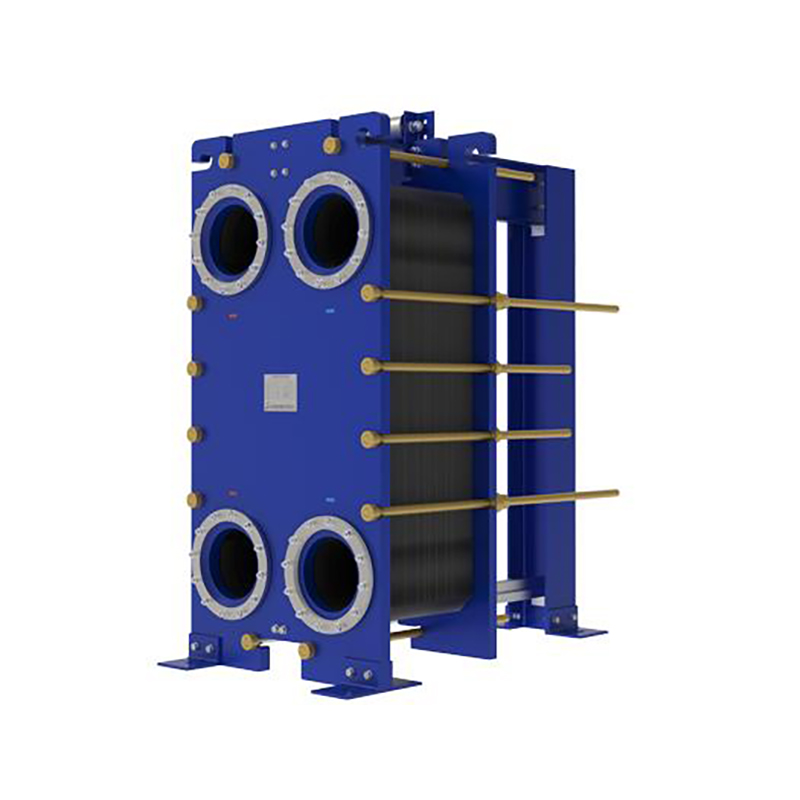

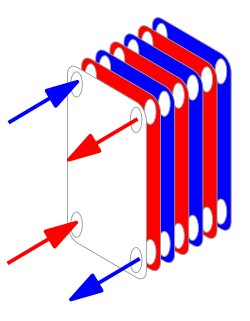

A Plate and Shell Heat Exchanger (PSHE) is a hybrid heat transfer system that ingeniously combines the compact, efficient plate design of a Plate Heat Exchanger (PHEX) with the robust, high-pressure shell design of a Shell and Tube Heat Exchanger (STHE). This configuration consists of a bundle of corrugated metal plates, typically laser-welded together in a circular pattern to form a core. This plate pack is then encased within a cylindrical pressure shell, creating two separate flow paths. One fluid, often the service or utility fluid, flows through the gaps between the plates within the shell (the plate side), while the other fluid flows through the remaining space inside the shell surrounding the plate pack (the shell side). The corrugated plates induce intense turbulence in the fluids, which is the key to its high thermal efficiency. This design is engineered to handle challenging applications involving high temperatures, high pressures, significant temperature crosses, and fluids containing particulates or fibers that would clog traditional plate-and-frame exchangers. They are not gasketed, making them suitable for a wider range of media compared to their gasketed counterparts.

The operational principle of the Plate and Shell Heat Exchanger leverages the best attributes of its parent designs. The corrugated plates provide a massive surface area for heat transfer within a remarkably small footprint, a characteristic inherited from plate-type exchangers. Studies and manufacturer data, such as from Alfa Laval's Packinox or Vahterus's PSHE units, indicate that PSHEs can achieve heat transfer coefficients that are 3 to 5 times higher than those of traditional shell and tube exchangers. This directly translates to requiring less surface area for the same duty, leading to material savings and a more compact unit. The fully welded plate pack is housed inside a strong shell, which provides the structural integrity to withstand high pressures, often cited in operational ranges up to 100 bar (1450 psi) and temperatures exceeding 500°C (932°F). This makes them exceptionally versatile. They are extensively used in critical industrial processes including oil and gas refining (e.g., crude oil cooling, gas compression cooling), chemical processing, power generation (for intercooling and aftercooling), and as evaporators or condensers in large HVAC and refrigeration systems. Their ability to manage a temperature cross, where the outlet temperature of one fluid falls below the outlet temperature of the other, is a significant advantage in energy recovery applications, maximizing heat recuperation.

The primary advantages of the Plate and Shell Heat Exchanger stem from its hybrid design, offering a unique combination of performance, reliability, and operational flexibility that is difficult to match with other exchanger types. The most prominent benefits include superior thermal efficiency, exceptional durability under extreme conditions, remarkable compactness, and reduced lifecycle costs. These exchangers are specifically engineered to solve the limitations of both shell and tube and traditional plate heat exchangers, providing a robust solution for the most demanding heat transfer challenges. They excel in applications involving high-fouling streams, large temperature and pressure differentials, and aggressive media, making them a preferred choice for engineers looking to optimize process efficiency and plant safety while minimizing the physical footprint of equipment.

The superior heat transfer efficiency is quantified by high K-values, often between 3000-7000 W/m²°C for water-to-water duties, drastically reducing the required heat transfer surface area by up to 80% compared to a shell and tube unit for the same duty, as per performance data from manufacturers like Tranter and APV. This compactness leads to direct savings on space, weight, and initial infrastructure costs. The robust construction, with a fully welded plate pack and a carbon or stainless steel shell, ensures high pressure and temperature resistance, eliminating the risk of gasket failure and minimizing maintenance downtime. This durability is crucial in industries like oil and gas, where safety and reliability are paramount. Furthermore, the high turbulence created by the plate corrugations minimizes fouling, and the design often allows for mechanical cleaning of the shell side, ensuring long-term performance stability and reducing cleaning costs. The ability to handle temperature crosses and close temperature approaches (as low as 1-2°C in some cases) maximizes heat recovery, leading to substantial energy savings and a lower carbon footprint for the plant. This combination of low operational costs, minimal maintenance, and high energy efficiency results in a significantly lower total cost of ownership over the exchanger's lifespan, making it a highly economical investment for heavy industries.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

You can see clear differences between welded block...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

Industries in 2025 achieve higher efficiency by ad...

More

Understand the frame plate—the fixed head of a pla...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Maintenance EngineerThis plate and shell heat exchanger has been incredibly reliable in our chemical processing plant. The compact design saves significant space and its efficiency has reduced our energy costs. The build quality is outstanding, showing no signs of corrosion after 18 months of continuous operation with aggressive media.

Sarah Chen

HVAC Project ManagerWe installed these units for a large district heating project and the performance is exceptional. The thermal efficiency is higher than promised, which greatly improves our overall system COP. The gasketed design makes maintenance a breeze. Highly recommended for any large-scale HVAC application.

David Wilson

Chief EngineerAs a chief engineer on marine vessels, I appreciate equipment that can handle tough conditions. This heat exchanger performs flawlessly in high-vibration marine environments and handles large temperature differentials without issues. We've standardized on this model across our fleet for its durability and ease of service.

Jennifer Park

Process Design EngineerThe precision engineering of this plate and shell exchanger is impressive. In our pharmaceutical manufacturing processes where temperature control is critical, this unit maintains ±0.5°C accuracy consistently. The sanitary design meets all our clean-in-place requirements perfectly. A vital component in our production line.