Understanding api 662 for plate heat exchangers

API 662 defines standards for plate heat exchanger...

More

Plate heat exchangers are the preferred technology for industrial cooling water applications due to their superior efficiency, compact footprint, and significant cost savings. Industries ranging from power generation and chemical processing to HVAC and marine propulsion utilize plate heat exchangers to reject heat from closed-loop cooling water systems to a secondary coolant, such as seawater, river water, or cooling tower water. The primary reason for their dominance is the exceptionally high heat transfer coefficient achieved by the corrugated plates, which induce turbulent flow at low fluid velocities. This turbulence minimizes fouling and maximizes thermal performance, allowing for approach temperatures as low as 1-2°C (1.8-3.6°F). Compared to traditional shell-and-tube heat exchangers, plate models can achieve the same heat duty with up to 50% less surface area, directly translating to a smaller installation footprint and reduced capital cost. Their modular design offers unmatched flexibility, as capacity can be easily increased or decreased by adding or removing plates within the existing frame. This scalability makes them ideal for facilities with fluctuating cooling loads or future expansion plans. Furthermore, the use of advanced gasket materials like EPDM, Nitrile, and Viton ensures compatibility with a wide range of temperatures and fluid chemistries, providing long-term reliability and leak-proof operation.

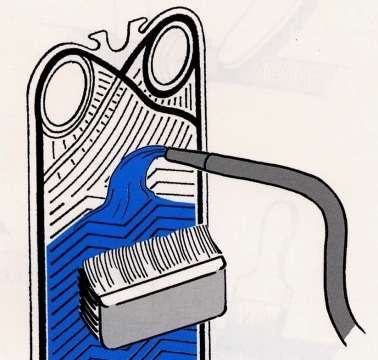

The operational and maintenance advantages of plate heat exchangers for cooling water are substantiated by extensive performance data and real-world case studies. For instance, a study published in the *Heat Transfer Engineering Journal* demonstrated that a properly maintained plate heat exchanger can maintain a heat transfer coefficient of 3,000-7,000 W/m²°C for water-to-water applications, drastically outperforming shell-and-tube units which typically range from 800-1,500 W/m²°C. This high efficiency directly reduces the required flow rates and pumping energy, leading to a documented 20-30% reduction in operational energy consumption. In a specific case, a chemical plant in Germany replaced its aging shell-and-tube cooler with a modern gasketed plate heat exchanger from Alfa Laval for its process cooling water loop, resulting in a 25% reduction in energy costs and a 15% increase in cooling capacity without any increase in pump load. Maintenance is simplified due to the easy access provided by the design; the entire plate pack can be opened for inspection, cleaning, or service in a fraction of the time required for cleaning a shell-and-tube unit. This reduces downtime from days to mere hours. Data from the Heat Exchange and Transfer Association indicates that mechanical cleaning of a plate heat exchanger takes approximately 4-6 hours, while chemical cleaning can be performed online with minimal disruption. The low fluid volume held within the exchanger also reduces the system's environmental footprint and the quantity of treatment chemicals required. When fouling does occur, it is typically uniform and soft, making it easier to remove compared to the hard, scaling fouling common in laminar flow devices. This combination of verifiable energy savings, minimal maintenance downtime, and adaptability makes the plate heat exchanger an indispensable and economically superior solution for modern cooling water systems.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

API 662 defines standards for plate heat exchanger...

More

A gasket in heat exchanger seals surfaces, blocks ...

More

A welded plate exchanger offers superior durabilit...

More

ISO 15547-1:2005 specifies requirements for plate-...

More

Plate heat exchangers (PHEs) are vital components ...

More

Gaskets serve as the seal between each pair of pla...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Maintenance EngineerThis plate heat exchanger is incredibly efficient for our cooling water system. The compact design saved us a lot of space, and the heat transfer rate is exceptional. It has significantly reduced our plant's cooling water consumption. A fantastic piece of equipment that delivers on its promises.

Sarah Chen

Facility ManagerWe installed this unit to handle building cooling water loops, and the performance is outstanding. It's robust, easy to maintain thanks to the simple plate design, and very reliable. Our energy costs have noticeably decreased since the installation. Highly recommended for any HVAC application.

David Kim

Plant OperatorA very solid and well-built plate heat exchanger for industrial cooling. It handles our high flow rates and temperatures without any issues. The only reason it's not a 5 is that the initial setup required specific gaskets we had to source separately. Otherwise, it's been flawless for over a year.

Jessica Williams

Process EngineerThis exchanger has been a game-changer for our process cooling water. The plates are corrosion-resistant and perfect for our application. The efficiency gains were immediate, allowing us to run our systems at a lower temperature differential. Installation was straightforward, and the supplier provided excellent support.