Plate Heat Exchanger Solution For Metallurgy Industry

Advanced heat exchanger technology drives progress in the metallurgy industry. SHPHE’s Wide Gap Welded Plate Heat Exchanger delivers high-pressure resistance, corrosion protection, and energy efficiency. With patented design and global certifications, SHPHE supports industrial projects in over 20 countries, meeting rigorous heat transfer demands in metallurgy applications.

Metallurgy Industry Challenges

High Temperatures and Corrosive Media

Metallurgy processes expose equipment to extreme conditions. Operators often encounter high temperatures and aggressive chemical environments that threaten the integrity of every heat exchanger in the plant. Common corrosion types include:

Oxidation, where metals react with oxygen and form unstable oxides

Sulfidation, which results from sulfur-containing gases attacking metal surfaces

Carburization, caused by carbon-rich gases leading to embrittlement

Metal dusting, a severe form of carburization that creates pitting

Ash or salt deposit corrosion, where deposits break down protective layers

Halogen corrosion, involving halogen gases forming volatile compounds

Molten metal and molten salt corrosion, which attack at elevated temperatures

Nitridation, where nitrogen gases degrade metal

These corrosive conditions appear in many industrial settings, including steel and aluminum production. The following table highlights typical environments:

Temperature Range (°C) | Corrosive Media | Corrosion Behavior and Notes |

30 | Chloride ions (Cl−) | Limited pitting; oxide film mostly intact |

30–45 | Chloride ions (Cl−) | Pitting and crevice corrosion expand; passivation film destroyed |

40–45 | Chloride ions (Cl−) | Rapid formation of corrosion products |

50 | Chloride ions (Cl−) | Corrosion rate varies with environment |

Conventional heat exchanger designs struggle under these conditions. Gasket materials degrade above 150°C, and stainless steel plates deform, leading to leaks and frequent maintenance. Only advanced materials and robust designs can ensure reliable heat transfer in such harsh industrial environments.

Energy Efficiency Needs

Energy efficiency remains a top priority for metallurgy facilities. Operators seek to maximize heat transfer rates while minimizing losses. Key drivers include:

Increasing the temperature difference between process streams

Selecting materials with high thermal conductivity

Enhancing convective heat transfer through improved fluid flow

Optimizing system geometry to reduce energy waste

Innovative heat exchanger designs, such as microchannel and spiral types, boost efficiency by increasing surface area and turbulence. Real-time monitoring and digital control further optimize performance. These strategies help industrial plants lower operational costs and reduce environmental impact.

Space and Integration Constraints

Space limitations challenge every metallurgy facility. Traditional shell-and-tube heat exchangers require large footprints and extra room for maintenance. Plate heat exchangers offer a compact, modular alternative, fitting into tight spaces without sacrificing performance. The table below compares space considerations:

Heat Exchanger Type | Space Considerations | Additional Notes |

Shell-and-tube | Large footprint | Difficult to clean; requires extra maintenance space |

Plate-and-frame | Compact design | Modular; easier maintenance and integration |

Integration constraints also influence technology selection. Engineers must consider piping layouts, industry standards, and compatibility with existing infrastructure. The right heat exchanger design balances thermal efficiency, reliability, and seamless integration within the industrial plant.

Plate Heat Exchanger Solutions

Product Features

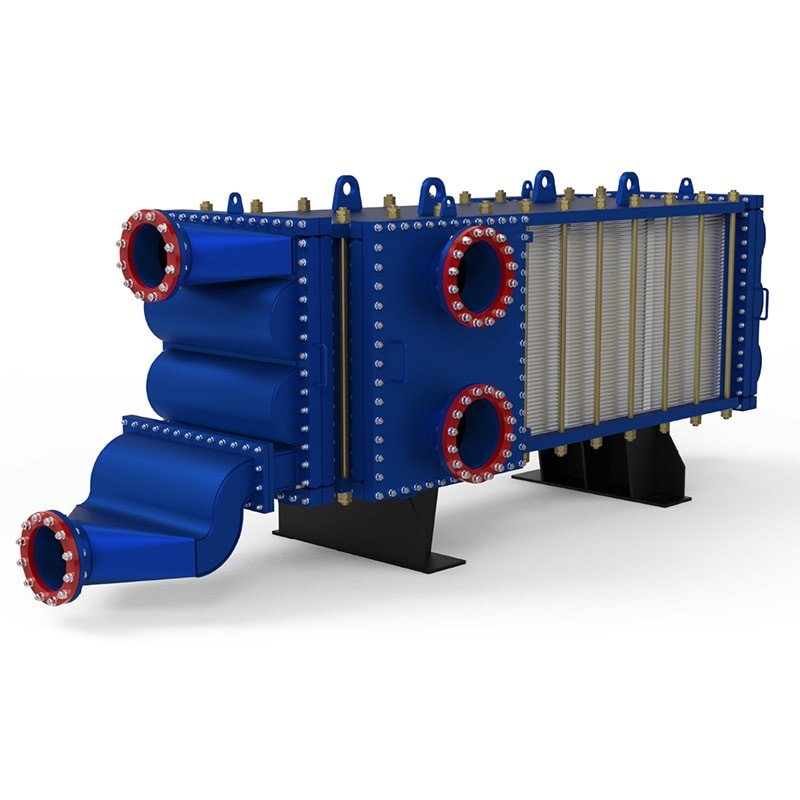

SHPHE’s Wide Gap Welded Plate Heat Exchanger stands out as a high-performance solution for metallurgy applications. The fully welded exchanger construction ensures durability and safety under extreme operating conditions. Engineers designed this plate heat exchanger to handle high pressures and temperatures, making it suitable for the most demanding industrial environments.

The use of advanced materials such as 316L, Duplex SS, 254SMO and C-276 provides exceptional corrosion resistance. These materials withstand aggressive chemicals and high-stress conditions found in metallurgy plants. The design temperature range extends from -46°C to 350°C, and the pressure range covers vacuum up to 3.0 MPa. This versatility allows the plate heat exchanger to operate reliably in a wide variety of processes.

Welded Plate Heat Exchanger features optimized media distribution and cross-corrugated plates. This design increases heat transfer efficiency by up to 15% compared to traditional shell-and-tube exchangers. Self-cleaning effect reduces fouling by up to 40%. Perpendicular corner guiding ensures perfect plate alignment, which simplifies maintenance and reduces service time.

Note: The compact design of plate heat exchangers allows for easy integration into existing systems, even where space is limited. This feature is especially valuable in metallurgy facilities with tight layouts.

Performance Metric | SHPHE Welded Plate Heat Exchanger Advantage | Comparison to Shell-and-Tube Exchangers |

Heat Transfer Efficiency | Up to 15% higher due to optimized design | Lower efficiency |

Self-Cleaning Capability | Up to 40% improvement, less fouling | Higher fouling risk |

Pressure Handling | Enhanced with thinner, welded plates | Lower pressure limits |

Maintenance | Fast service, perfect alignment | Longer service times |

Special Plate Types | Studded type, corrugated type | Less flexible for aggressive fluids |

Applications in Metallurgy

Metallurgy plate heat exchangers play a critical role in steel, aluminum, and non-ferrous metal processing. Metallurgy plants rely on these heat exchangers for smelting, refining, and waste heat recovery. In steel manufacturing, plate heat exchangers improve energy efficiency and help reduce CO2 emissions. They support electric arc furnaces and basic oxygen furnaces by recovering waste heat and preheating process streams.

In aluminum production, plate heat exchangers optimize energy-intensive steps such as digestion, evaporation, and heating of alumina liquor. These systems also contribute to sustainable operations by enabling post-combustion carbon capture and recovering waste heat from off-gases. Regenerative stoves in blast furnaces use plate heat exchangers to preheat blast air, which enhances fuel efficiency.

Metallurgy facilities select plate heat exchangers for their ability to handle aggressive fluids and high temperatures. The use of stainless steel, duplex alloys, and specialty nickel alloys ensures durability and resistance to corrosion. These materials provide the necessary thermal conductivity and mechanical strength for reliable operation.

Plate heat exchangers support smelting, refining, and waste heat recovery in steel plants.

They optimize digestion, evaporation, and heating processes in aluminum production.

Facilities use them for post-combustion carbon capture and energy recovery.

Regenerative stoves in blast furnaces rely on plate heat exchangers to preheat air and improve fuel efficiency.

The selection of advanced materials ensures long service life and minimal maintenance.

SHPHE’s global certifications, including ISO9001, ISO14001, OHSAS18001, and the ASME U Certificate, demonstrate a commitment to quality and safety. The company’s service network spans over 20 countries, providing reliable support for metallurgy clients worldwide.

Digital Monitoring and Maintenance

The Smart Eye digital monitoring system transforms the way metallurgy plants manage plate heat exchangers. This system uses military-grade sensors to monitor temperature, pressure, vibration, and flow rate in real time. Microsecond-level sampling detects subtle operational changes, enabling early identification of potential issues.

Artificial intelligence and advanced thermal models analyze data with high accuracy. The system predicts tube corrosion up to 30 days in advance and diagnoses over 150 fault modes. Automatic maintenance plan generation shifts maintenance from reactive to proactive, reducing unplanned downtime and lowering maintenance costs by more than 20% each year.

A 3D dashboard provides thermal maps, energy efficiency charts, and lifespan predictions. The system automatically generates spare parts lists, maintenance schedules, and cost-benefit reports. Integration with SCADA and MES platforms allows for remote monitoring and early warnings through IoT technology.

Tip: Predictive maintenance, enabled by digital monitoring, optimizes preventive tasks and eliminates unnecessary work. Accurate asset data and historical records support reliability analysis, helping facilities adjust maintenance frequency and scope for safer, more reliable operation.

The Smart Eye system also improves operational efficiency. Plants can achieve up to 12% energy savings and a 23% increase in equipment efficiency. The accumulation of full lifecycle data supports continuous process improvement and digital transformation.

Plate Heat Exchangers: Best Practices

Selection and Sizing

Selecting the right plate heat exchanger for metallurgy operations requires careful consideration of several factors. Engineers evaluate material compatibility, corrosion resistance, and mechanical strength. Common choices include stainless steel for moderate corrosion, duplex alloys for higher resistance, and titanium or nickel alloys for extreme environments. Cleanability and durability remain essential, as metallurgy processes often involve aggressive fluids and frequent cleaning cycles.

Key sizing steps include:

1. Calculate the required heat transfer duty for the specific application.

2. Assess fluid flow rates and temperature differences to determine the necessary surface area.

3. Select the optimal number of plates and flow arrangement for efficient heat transfer.

4. Verify that pressure drops remain within acceptable limits to maintain system integrity.

Proper sizing ensures uniform fluid distribution, reduces localized corrosion, and extends the lifespan of the heat exchanger.

Maintenance Strategies

Effective maintenance strategies keep plate heat exchangers operating reliably in harsh metallurgy environments. Facilities use corrosion-resistant materials and protective coatings to minimize risk. Regular cleaning—both chemical and mechanical—removes deposits and prevents fouling. Operators monitor performance with digital systems, enabling early detection of issues and proactive maintenance planning.

Maintenance Method | Description |

Chemical Cleaning | Removes scale and fouling from plates |

Digital Monitoring | Tracks temperature, pressure, and flow in real time |

Protective Coatings | Enhances corrosion resistance |

Operator Training | Ensures safe and effective maintenance |

Performance Optimization

Optimizing plate heat exchangers involves adjusting operational parameters such as flow rates and temperature differentials. Engineers select plate geometries that enhance turbulence and heat transfer.

Digital monitoring systems, like SHPHE’s Smart Eye, provide real-time data for predictive maintenance and process adjustments. Regular inspections and timely cleaning prevent fouling, ensuring consistent performance and energy efficiency.

SHPHE’s Welded Plate Heat Exchanger delivers reliable heat exchanger performance, supporting sustainability goals in metallurgy. Advanced design and materials reduce energy use and emissions. Facilities benefit from:

Efficient heat exchanger operation and waste heat recovery

Lower maintenance costs and extended equipment life

Structured evaluation for heat exchanger system upgrades

Evaluate current heat exchanger systems and consult SHPHE for tailored heat transfer solutions.

FAQ

What materials does SHPHE use for the Welded Plate Heat Exchanger?

SHPHE uses 316L, Duplex SS, 254SMO, and C-276. These materials provide excellent corrosion resistance and durability in metallurgy environments.

How does the Smart Eye system benefit metallurgy operations?

The Smart Eye system enables real-time monitoring.

It predicts faults, reduces downtime, and supports proactive maintenance for reliable heat exchanger performance.

If you need further consultation and discussion, please feel free to contact us.

Email: info@shphe.com

WhatsApp /Cell: +86 15201818405