Printed Circuit Heat Exchanger Innovations Driving Sustainability

Printed circuit heat exchanger innovations are reshaping sustainability in industrial sectors. The market shows strong growth, driven by regulatory shifts and rising demand for compact, energy-efficient solutions. Shanghai Plate Heat Exchanger leads with advanced technology, meeting industry needs for high-performance equipment. Rapid trends in automation and smart monitoring reflect ongoing innovation.

Sustainability Impact of Printed Circuit Heat Exchangers

Energy Efficiency and Emissions

Printed circuit heat exchangers play a vital role in advancing energy-efficient systems across the industry. Their compact design and innovative channel architecture maximize heat transfer efficiency while minimizing the required footprint. This technology stands out in the market for its ability to deliver unmatched thermal conductivity and reduce fluid volume needs. The result is lower energy consumption and reduced operational costs.

Shanghai Plate Heat Exchanger offers printed circuit heat exchangers engineered for high-demand environments. These products help facilities meet strict emissions regulations and support environmental sustainability goals. The integration of printed circuit heat exchangers into industrial processes leads to significant reductions in greenhouse gas emissions. Lower energy consumption directly translates to fewer emissions, making these exchangers essential for sustainable energy applications.

Note: Facilities using printed circuit heat exchangers often report improved compliance with emission targets and enhanced overall efficiency.

The following table summarizes the measurable impacts of printed circuit heat exchangers on energy efficiency in industrial applications:

Attribute | Description |

|---|---|

Compact Design | PCHEs utilize intricate channel architectures that maximize heat transfer efficiency in a small footprint. |

High Efficiency | They provide unmatched thermal conductivity and minimal fluid volume requirements. |

Adaptability | PCHEs are designed to operate under extreme conditions, enhancing their applicability in various sectors. |

Reduced Operational Costs | Their efficiency leads to lower energy consumption and operational expenses. |

Compliance with Emission Targets | Integration of PCHEs helps industries meet stringent emissions regulations. |

Printed circuit heat exchangers facilitate high heat transfer coefficients and reduced pressure drops. They are essential in renewable energy power cycles and industrial process heat recovery. Innovative channel geometries and fin configurations optimize flow uniformity and structural integrity. Continuous refinement of designs enhances thermal-hydraulic performance, contributing to energy efficiency and supporting environmental sustainability.

Resource and Space Optimization

Resource and space optimization is a key advantage of printed circuit heat exchangers. Their compact structure allows for installation in areas where space is limited, which is common in modern industrial facilities. The small footprint of these exchangers enables companies to maximize production capacity without expanding physical infrastructure.

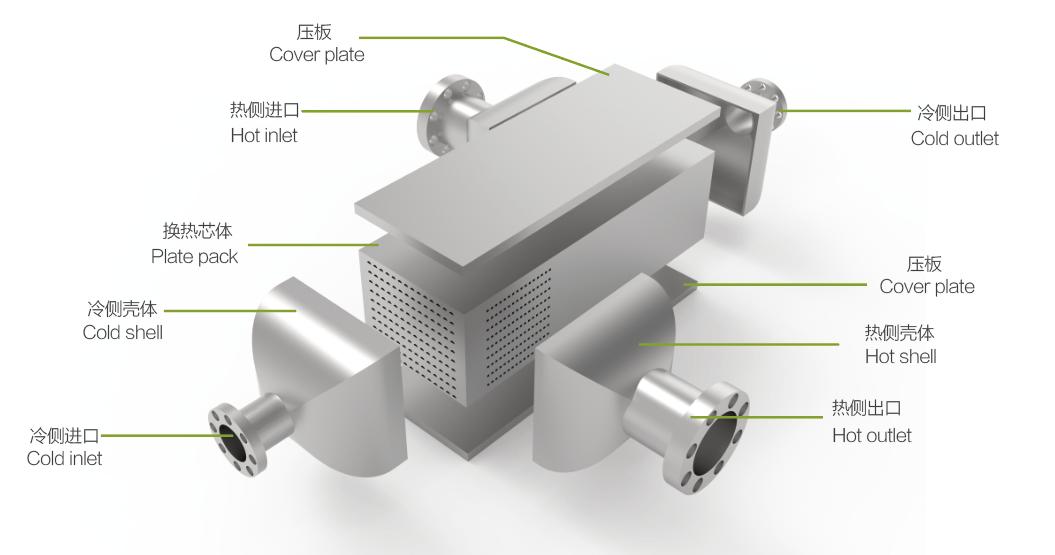

Shanghai Plate Heat Exchanger’s printed circuit heat exchangers are constructed from thin metal plates using advanced chemical etching and diffusion bonding techniques. This process creates robust, leak-proof units that withstand high pressures and temperatures. The efficient use of materials reduces waste and supports sustainable energy practices.

Printed circuit heat exchangers require less raw material compared to traditional heat exchanger technology.

Their design enables flexible customization for specific process requirements, optimizing resource allocation.

The reduced size and weight simplify transportation and installation, lowering logistical costs.

By choosing printed circuit heat exchangers, companies can achieve higher efficiency, minimize resource consumption, and contribute to environmental sustainability. These benefits position Shanghai Plate Heat Exchanger as a leader in the market, offering solutions that drive sustainable growth and operational excellence.

Printed Circuit Heat Exchanger Fundamentals

Design and Technology Overview

Printed circuit heat exchangers stand out in the market for their compact systems and advanced engineering. Shanghai Plate Heat Exchanger uses stainless steel printed circuit heat exchangers that feature chemically etched microchannels and diffusion-bonded plates. This process creates a robust, leak-proof structure that operates reliably under extreme temperatures and pressures. The technology supports applications in nuclear power, LNG, and renewable energy, where durability and high thermal performance are essential.

Key technical features include:

Microchannel architecture for superior heat transfer efficiency

Diffusion bonding for exceptional mechanical strength

Customizable plate patterns to match specific process needs

The use of stainless steel and nickel alloys ensures corrosion resistance and long service life. These advanced printed circuit heat exchangers deliver a heat transfer rate much higher than traditional designs, making them ideal for demanding industrial environments.

Why PCHEs Matter for Sustainability

Printed circuit heat exchangers directly support sustainability goals by maximizing efficiency and minimizing resource use. Their compact design reduces material waste and lowers installation costs. Real-time digital monitoring enables operators to optimize performance and reduce downtime. Customization options allow each unit to meet unique operational requirements, further improving efficiency and reducing environmental impact.

Choosing Shanghai Plate Heat Exchanger means investing in technology that drives both operational excellence and environmental responsibility.

These features position printed circuit heat exchangers as a cornerstone of modern heat exchanger technology, supporting sustainable growth across the industry.

Market Trends and Innovations in Heat Exchanger Technology

Advanced Materials and Microchannel Design

Recent market trends show a strong shift toward advanced materials and microchannel designs in printed circuit heat exchangers. Manufacturers now use stainless steel, nickel alloys, and titanium to improve durability and performance. These advanced materials allow heat exchangers to operate in extreme environments. Microchannel technology brings miniaturization, high efficiency, and lightweight construction. Dimpled tubes and tube inserts further boost heat transfer, increasing capacity by up to 50% and reducing energy costs. Computational tools and artificial intelligence now optimize designs, driving technological innovation and efficiency. Shanghai Plate Heat Exchanger leads these advancements, offering products that meet the global demand for sustainable and efficient solutions.

Digital Integration and Smart Monitoring

Digital integration is transforming heat exchanger technology. IoT sensors and real-time monitoring systems now track performance and predict maintenance needs. This reduces downtime and extends equipment lifespan. Smart control systems make dynamic adjustments, improving energy efficiency. These technological advancements help operators maintain peak performance and lower operational costs. Shanghai Plate Heat Exchanger incorporates these features, ensuring their printed circuit heat exchangers remain at the forefront of innovation.

Hydrogen and Renewable Applications

Printed circuit heat exchangers play a vital role in hydrogen and renewable energy sectors. The table below highlights key applications:

Application Area | Description |

|---|---|

Hydrogen Refueling Stations | Precools hydrogen, improving safety and refueling efficiency. |

Renewable Energy | Supports high-temperature storage and carbon capture processes. |

High-Pressure Systems | Handles pressures up to 1,250 bar, suitable for advanced energy applications. |

As renewable energy deployment accelerates, growth trends indicate rising demand for advanced heat exchangers. Shanghai Plate Heat Exchanger continues to drive innovation, supporting the transition to a sustainable energy future.

Industry Applications of Printed Circuit Heat Exchangers

Power Generation and Renewables

Printed circuit heat exchangers have become essential in power generation and renewable energy projects. Their compact design and high energy efficiency make them ideal for advanced applications. The following table highlights key areas where these exchangers deliver value:

Application Area | Description |

|---|---|

Solid Oxide Fuel Cells (SOFC) | Enhances energy efficiency in clean energy production. |

Supercritical Carbon Dioxide (SCO2) | Facilitates efficient power generation systems. |

Nuclear Power Plants | Improves energy efficiency and safety in nuclear energy production. |

Hydrogen Energy | Supports production, storage, and transportation of hydrogen for clean energy. |

Shanghai Plate Heat Exchanger offers solutions that meet the demands of these sectors, supporting sustainable energy and reliable operation.

Hydrogen and LNG Sectors

Printed circuit heat exchangers play a critical role in hydrogen integration and LNG processing. Their ability to operate at high pressures and cryogenic temperatures ensures efficient and safe operations. Key applications include:

Gas processing and liquefaction in LNG plants, where they recover heat in pre-cooling, condensation, and boil-off gas circuits.

Hydrogen production and refining, where they handle high-pressure hydrogen services for processes like steam methane reforming and electrolysis.

These exchangers are integral to hydrogen liquefaction and storage systems.

They enable efficient thermal exchange in carbon capture and waste heat recovery, supporting greener operations.

Studies show that a channel bending angle of 15° in these exchangers optimizes convective heat transfer, while airfoil fins further enhance thermal and hydraulic efficiency.

Industrial Process Optimization

Industrial facilities rely on printed circuit heat exchangers for process optimization. Their compact, all-welded, gasket-free construction ensures durability and minimizes failure points. The table below summarizes their main benefits:

Benefit | Description |

|---|---|

Compact Design | Saves space in industrial applications. |

High Thermal Efficiency | Contributes to energy conservation. |

Durability | Withstands extreme temperatures and pressures, reducing system failures. |

Modular Nature | Allows tailored solutions for complex industrial settings. |

These advanced heat exchangers reduce equipment size, lower capital expenditures, and support efficient, reliable operations. Shanghai Plate Heat Exchanger provides customizable solutions for diverse industry needs, driving market growth and operational excellence.

Challenges and Future Trends in Heat Exchanger Technology

Technical and Market Barriers

Printed circuit heat exchangers have transformed many industry applications, yet several barriers limit wider adoption. Manufacturers face high initial costs and complex manufacturing processes. Longer lead times often result from intricate design requirements. The absence of standardized testing and certification procedures creates uncertainty for buyers. Additional challenges include fluctuations in raw material prices and supply chain disruptions. Many customers need education on the benefits of advanced heat exchanger technology.

High initial costs compared to traditional heat exchangers

Complexity in design and manufacturing processes

Need for customer education on the benefits of PCHEs

Fluctuations in raw material prices

Supply chain disruptions

Shanghai Plate Heat Exchanger addresses these challenges by investing in technological advancements and customer support, ensuring reliable solutions for demanding market needs.

Opportunities for Sustainable Growth

The market for heat exchanger technology continues to expand, driven by trends in energy efficiency and sustainability. Companies seek solutions that reduce environmental impact and improve operational performance. Advancements in manufacturing enable more complex and efficient designs. Emerging markets, especially in Asia-Pacific, offer significant growth potential due to rapid industrialization. Strategic partnerships and collaborations enhance research and development efforts. Integration of digital technologies and IoT capabilities improves operational efficiency and monitoring.

Innovation Type | Description |

|---|---|

Digital Technologies | Smart heat exchangers with sensors for real-time monitoring and predictive maintenance. |

Energy-efficient Designs | Waste heat recovery, variable flow controls, and smart monitoring for improved efficiency. |

Advanced Materials | Bio-based composites and nanomaterials for better thermal performance and reduced footprints. |

Shanghai Plate Heat Exchanger leads the industry by offering innovative products that support sustainable growth and meet evolving market demands.

Printed circuit heat exchanger innovations are shaping a sustainable future for industry. Key trends include:

Additive manufacturing enables complex designs that boost thermal efficiency.

Advanced nickel and stainless steel blends improve durability and lower lifecycle costs.

Regulatory changes drive adoption of high-performance, energy-efficient systems.

Shanghai Plate Heat Exchanger leads the market with solutions that deliver 400% higher heat transfer efficiency and significant CO₂ reductions. Their advanced modular designs support industries in achieving sustainability goals. Companies should consider adopting these technologies and investing in further research to unlock new opportunities for sustainable growth.

FAQ

What makes printed circuit heat exchangers different from traditional designs?

Printed circuit heat exchangers offer higher efficiency, smaller size, and greater durability. Shanghai Plate Heat Exchanger provides advanced models for demanding industrial applications.

Can printed circuit heat exchangers handle extreme operating conditions?

Yes. Shanghai Plate Heat Exchanger’s printed circuit heat exchangers operate at temperatures up to 900°C and pressures up to 1,000 bar, ensuring reliable performance in harsh environments.

Are printed circuit heat exchangers customizable for specific processes?

Absolutely. Shanghai Plate Heat Exchanger customizes printed circuit heat exchangers to match unique flow rates, pressure drops, and thermal loads for optimal process efficiency.