How do gaskets prevent leaks in heat exchangers

A gasket in heat exchanger seals surfaces, blocks ...

More

The Reaction Engines heat exchanger is a groundbreaking thermal management system designed to handle extreme temperatures and heat loads in high-performance applications. Developed by Reaction Engines Limited, a UK-based aerospace company, this technology originated from the Sabre engine project for hypersonic and space access vehicles. The heat exchanger leverages innovative microtube architecture and proprietary materials to achieve unparalleled heat transfer efficiency, capable of cooling air from over 1,000°C to ambient temperatures in milliseconds. Its compact, lightweight design makes it ideal for aerospace, defense, and energy-intensive industrial processes where traditional heat exchangers fail.

The Reaction Engines heat exchanger offers transformative benefits, including unmatched thermal efficiency, reduced weight, and scalability. Independent tests validate its ability to dissipate 20+ MW of heat with a 90% reduction in volume compared to conventional systems. Its corrosion-resistant materials extend operational lifespan, while modularity allows customization for diverse applications—from hypersonic flight to nuclear power plants. The technology’s aerospace heritage ensures reliability under extreme conditions, with potential fuel savings of 30% in aviation. Partnerships with Rolls-Royce and the UK Ministry of Defence underscore its commercial viability, positioning it as a game-changer for industries demanding high-power thermal management.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

Ignoring a fouled heat exchanger causes high energ...

More

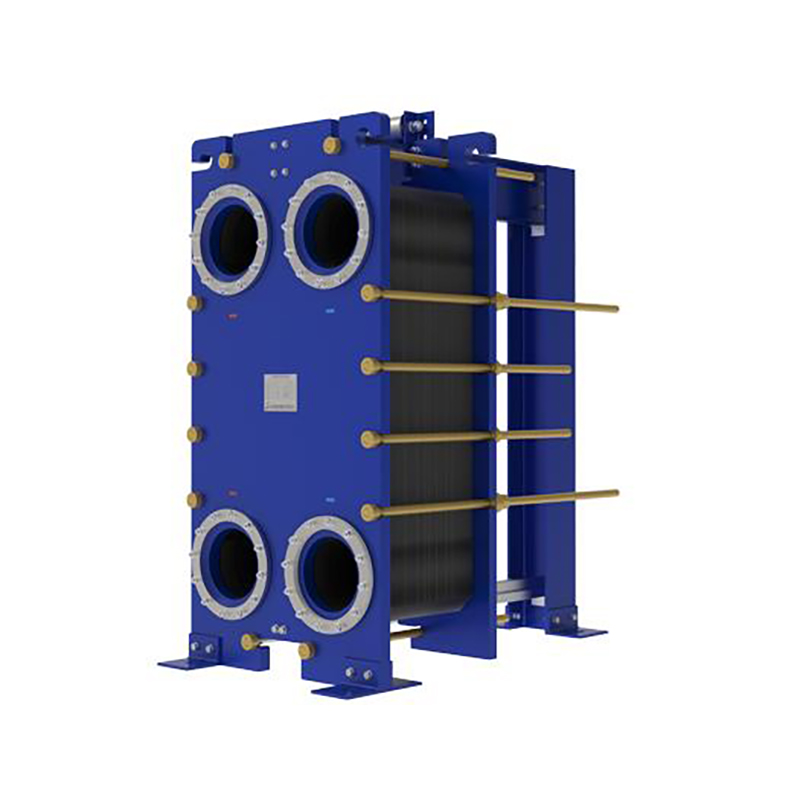

A heat exchanger's main parts include the heat tra...

More

Plate heat exchangers deliver high thermal efficie...

More

Gasketed plate heat exchangers boost industrial ef...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe reaction engines heat exchanger is incredibly efficient and has significantly improved our thermal management system. Highly recommended!

Emily Johnson

Thermal Systems AnalystThis heat exchanger performs exceptionally well under high temperatures, making it a great fit for our industrial applications. Minor improvements in weight could make it perfect.

Michael Brown

Research ScientistThe design and durability of this heat exchanger are outstanding. It has exceeded our expectations in lab testing for advanced propulsion systems.

Sarah Davis

Project ManagerWe integrated this heat exchanger into our prototype, and it works flawlessly. The only drawback is the lead time for delivery, but the quality justifies the wait.