Why a Welded Plate Beats Bolts Every Single Time

A welded plate creates a single, monolithic piece ...

More

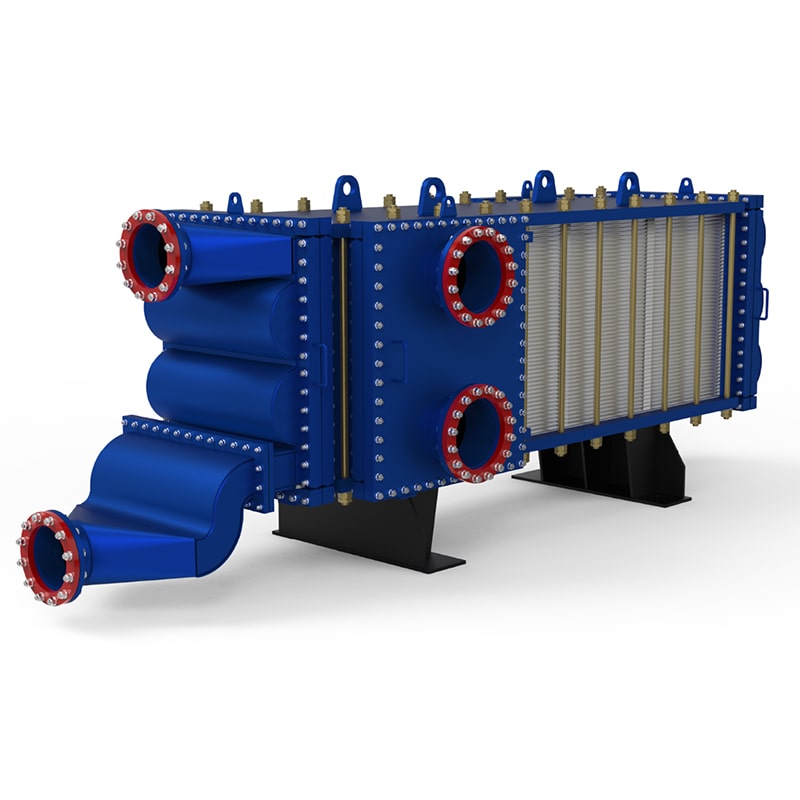

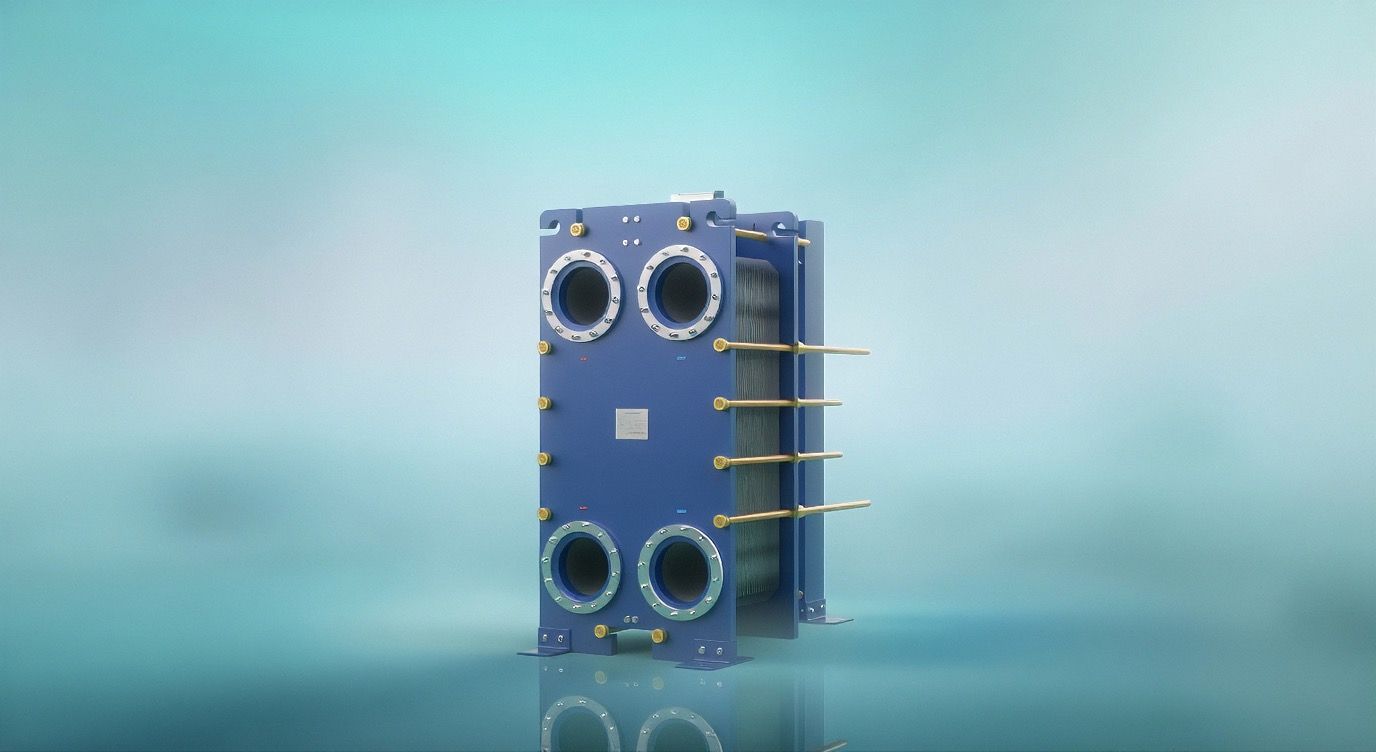

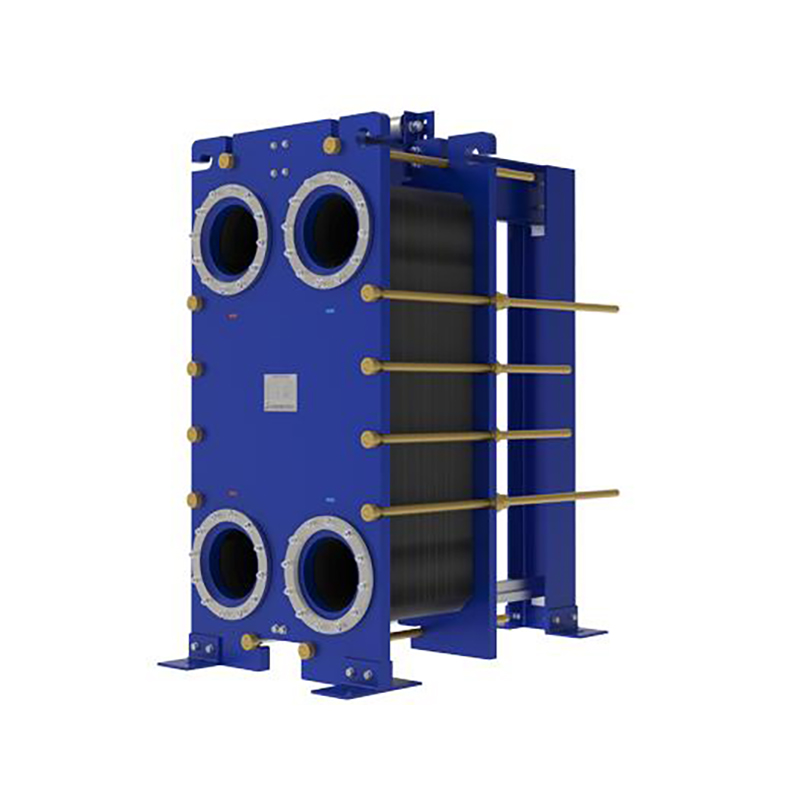

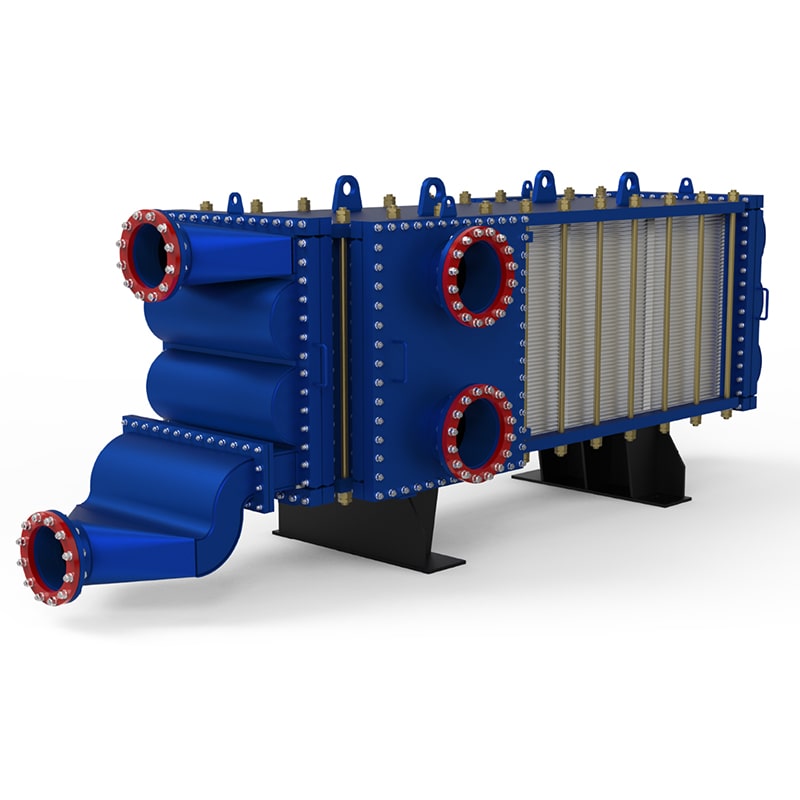

A Single Pass Condenser is a type of heat exchanger where the cooling fluid, typically water, flows through the tube side in a single, continuous path without reversing direction. The process fluid, often a vapor or gas, is condensed on the shell side by transferring its latent heat to the cooler water. This straightforward design ensures that the cooling medium enters at its lowest temperature and exits at its highest, maximizing the log mean temperature difference (LMTD), which is the driving force for heat transfer. This principle is fundamental to achieving high heat transfer coefficients and efficient condensation in a compact footprint. The thermal design is governed by fundamental equations, such as Q = U*A*ΔT_lm, where the overall heat transfer coefficient (U) is optimized for the specific fluids and operating conditions. This design is distinct from multi-pass configurations, which route the coolant back and forth, potentially reducing the effective temperature difference and requiring a larger surface area for the same duty.

The operational principle leverages a unimpeded flow path to minimize pressure drop on the coolant side, which is a critical factor in reducing pumping energy costs. In a typical shell and tube arrangement, the condenser tubes are arranged to provide a single, direct route from the inlet to the outlet nozzle. This simplicity is its greatest strength, as it avoids the flow restrictions and complexities associated with return bends and channels found in multi-pass units. The high thermal efficiency is directly linked to the maximum temperature gradient maintained across the entire length of the tubes. For instance, in a standard application cooling a refrigerant like Ammonia (R-717) with 30°C inlet cooling water, the single-pass design can achieve a U-value ranging from 450 to 600 W/m²°C, depending on tube material and fouling factors. This results in a significantly smaller required heat transfer area compared to a two-pass condenser handling the same load, often by a factor of 15-20%. The design is particularly effective in applications with a close temperature approach, where the difference between the process fluid condensation temperature and the coolant outlet temperature is small, as it fully utilizes the available cooling capacity.

The decision to use a Single Pass Condenser is driven by compelling economic and operational advantages centered on energy efficiency, lower lifecycle costs, and system reliability. In an industrial landscape where energy consumption constitutes a major portion of operational expenditure, the reduced pumping power requirement of a single-pass design offers immediate and sustained cost savings. Because the cooling water travels a shorter, less restrictive path, the pressure drop is significantly lower—often 50-70% less—than an equivalent multi-pass unit. This translates directly into smaller pumps and motors, reducing both the capital investment and the electrical load. For a large HVAC system or an industrial process requiring 1000 kW of heat rejection, this can mean a reduction in pumping power from 15 kW to perhaps 5 kW, saving thousands of dollars annually in electricity costs. Furthermore, the higher heat transfer efficiency means a more compact heat exchanger for the same duty, saving valuable floor space, which is a critical factor in many plant retrofits or new installations where space is at a premium. The simplicity of the design also correlates to enhanced reliability and easier maintenance. With fewer internal pass partitions and no complex water boxes, the potential for leakage is reduced, and mechanical cleaning of tubes is faster and more straightforward, minimizing downtime during scheduled maintenance periods.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

A welded plate creates a single, monolithic piece ...

More

ANSI/AHRI 400 defines rating methods, definitions ...

More

Accurate plate heat exchanger sizing requires defi...

More

Choosing the right thermal exchanger can lower ope...

More

Chemical plants demand robust solutions for heat t...

More

A heat exchanger's main parts include the heat tra...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Reynolds

HVAC TechnicianThis single pass condenser is incredibly efficient and robust. The build quality is superior, and it has significantly improved our system's cooling performance. A fantastic investment for any serious commercial application.

Sarah Chen

Plant EngineerWe installed this in our chemical processing plant, and the results are outstanding. Its single-pass design offers exceptional heat transfer, and it has been running flawlessly under constant demand. Highly reliable.

David Rodriguez

Facility ManagerA very well-made piece of equipment. The installation was straightforward, and it integrates perfectly with our existing systems. It's durable and performs exactly as advertised. A slight noise at peak operation prevents a perfect score, but still highly recommended.

Emily Watson

BrewmasterThis condenser is a game-changer for our craft brewery's distillation process. The temperature control is precise, leading to a purer product and more consistent batches. The single-pass efficiency has also reduced our water usage.