Stainless Steel Plate Heat Exchanger Makes Industrial Life Easier

Stainless Steel Plate Heat Exchanger Overview

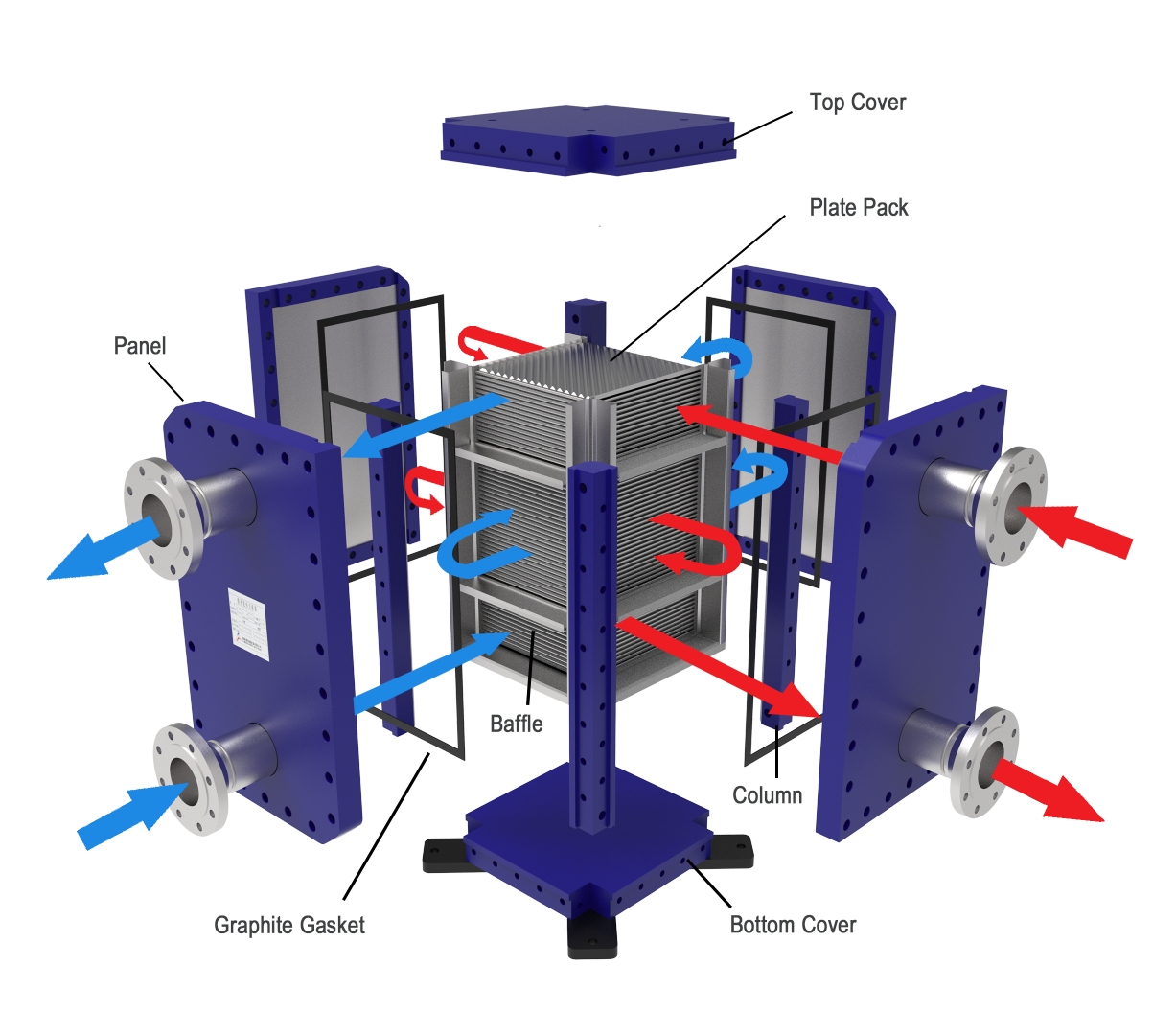

Structure and Function

A stainless steel plate heat exchanger uses a series of thin, corrugated plates to transfer thermal energy between two fluids. The plates create channels that guide hot and cold fluids in alternating paths, which increases turbulence and improves heat transfer rates. The compact design allows for efficient use of space in industrial settings. The table below outlines the core functions:

Core Function | Description |

|---|---|

Efficient Heat Transfer | Corrugated plates create channels for fluids, enhancing turbulence and heat transfer rates. |

Durability and Corrosion Resistance | Stainless steel construction withstands harsh conditions and resists corrosion. |

Versatility in Applications | Suitable for many industries, handling different fluids and environments. |

Compact Design | Smaller footprint than traditional heat exchangers, ideal for limited spaces. |

Easy Maintenance | Accessible design allows for straightforward cleaning and servicing. |

Plate heat exchangers maximize efficiency and longevity, ensuring smooth processes in industrial production.

Material Advantages

Stainless steel offers several important benefits for plate heat exchangers. The chromium in stainless steel forms a protective layer that guards against rust and corrosion. This resistance is vital in environments with exposure to water, steam, chemicals, and saltwater. Stainless steel’s durability helps extend the life of the heat exchanger, even in harsh industrial conditions.

Protects against corrosion and rust.

Performs well with chemicals, acids, and saltwater.

Maintains strength and longevity in demanding environments.

Innovation by Shanghai Plate Heat Exchanger

Shanghai Plate Heat Exchanger (SHPHE) leads the industry with the HT-Bloc Welded Plate Heat Exchanger. The HT-Bloc features a fully welded plate pack, eliminating the need for gaskets and allowing operation in high-pressure and high-temperature processes. The bolted frame enables easy disassembly for inspection and cleaning. Corrugated plates enhance turbulence, which boosts heat transfer efficiency and reduces fouling. The compact structure lowers installation costs and saves valuable space. SHPHE’s commitment to innovation ensures reliable, efficient, and customizable solutions for modern industrial thermal energy transfer needs.

Innovation/Advantage | Description |

|---|---|

Fully welded plate pack | Operates in high-pressure, high-temperature environments without gaskets. |

Easy disassembly | Bolted frame allows quick access for maintenance and cleaning. |

High heat transfer efficiency | Corrugated plates increase turbulence and efficiency. |

Compact structure | Small footprint reduces installation costs and saves space. |

SHPHE continues to set new standards in heat exchangers, making industrial life easier and more efficient.

Benefits of Heat Exchangers

Efficiency and Energy Savings

Heat exchangers play a key role in improving energy efficiency in industrial processes. They transfer heat between fluids, which helps recover waste energy and lower operating costs. The HT-Bloc from SHPHE uses advanced plate geometry to maximize heat transfer and minimize energy loss. This design leads to measurable savings:

Metric / Parameter | Value / Range | Description / Context |

|---|---|---|

Heat energy saved | 7,348,320 Btu/year | Annual energy savings in typical industrial use |

Cost savings | $304.30 USD/year | Reduced energy expenses |

Fuel oil saved | 81 gallons/year | Less fuel needed for heating |

Heat exchanger efficiency | 70% | High thermal efficiency |

Energy reduction percentage | 30% | Lower energy consumption in HVAC systems |

Economic payback period | ~3 years | Time to recover investment through energy savings |

These benefits support sustainability and improve overall system performance.

Durability and Corrosion Resistance

Stainless steel plate heat exchangers offer excellent durability. The material resists corrosion, even in harsh environments. The table below shows how different stainless steel grades perform:

Stainless Steel Grade | Corrosion Resistance | Mechanical Strength | Applications |

|---|---|---|---|

304 | Good | Moderate | General use |

316 | Excellent | High | Marine, chemical processing |

Duplex 2205 | Superior | Very High | Aggressive environments |

Super Duplex 2507 | Exceptional | Very High | Oil and gas, chemical plants |

This durability ensures long-term performance and reduces the need for frequent replacements.

Maintenance and Hygiene

The design of plate heat exchangers allows for easy maintenance. The HT-Bloc features accessible channels and openable bolted connections, which make cleaning and inspection simple. Regular cleaning removes deposits and maintains high performance. In industries like food processing, stainless steel surfaces support hygiene by preventing bacterial growth and allowing for effective cleaning protocols.

Tip: Easy maintenance reduces downtime and lowers operational costs, keeping production lines running smoothly.

Compact and Flexible Design

Compact heat exchangers save valuable space in industrial facilities. Their lightweight design and fewer connection points make installation easier and faster. The HT-Bloc’s modular structure allows users to customize and scale the system as needed. This flexibility supports efficient facility layouts and quick adaptation to changing process requirements.

Feature | Brazed Plate Heat Exchanger | Shell-and-Tube Heat Exchanger |

|---|---|---|

Size | Compact | Larger |

Thermal Performance | Similar or better | Standard |

Installation Complexity | Easy | Requires support structures |

SHPHE’s HT-Bloc combines these benefits to deliver reliable thermal efficiency and energy recovery for modern industry.

Industrial Applications of Stainless Steel Plate Heat Exchangers

Stainless steel plate heat exchangers serve as essential components in many industrial applications. Their versatility, durability, and efficiency make them a preferred choice for industries that demand reliable thermal management. The following sections explore how these heat exchangers support critical processes across various sectors.

Food and Beverage Processing

The food and beverage industry relies on stainless steel plate heat exchangers for processes that require strict hygiene and precise temperature control. These heat exchangers resist corrosion and provide a smooth, sanitary surface that prevents bacterial growth. Their excellent thermal conductivity ensures rapid and uniform heating or cooling, which is vital for temperature-sensitive products.

In pasteurization, stainless steel plate heat exchangers quickly heat dairy, juices, and other beverages to the required temperature, then cool them efficiently to preserve quality. This process maintains product safety and consistency. The equipment also supports cleaning in place (CIP) systems, ensuring stable hot water heating and effective sanitation.

Plate heat exchangers deliver efficient heat exchange.

They enable precise temperature control for consistent product quality.

They play a crucial role in pasteurization and cooling.

Sanitary designs support CIP systems and food safety.

Shanghai Plate Heat Exchanger’s HT-Bloc model stands out in this sector. Its fully welded construction and easy maintenance features help food processors achieve high efficiency and hygiene standards.

Chemical and Petrochemical

Chemical and petrochemical industries face harsh environments with corrosive fluids and high temperatures. Stainless steel plate heat exchangers excel in these settings because they resist corrosion and maintain high thermal efficiency. Grades like 310 and 310S stainless steel withstand aggressive chemicals and elevated temperatures, making them suitable for demanding chemical processes.

The HT-Bloc welded plate heat exchanger from Shanghai Plate Heat Exchanger offers several advantages for chemical plants:

Handles high pressures and temperatures.

Compact design reduces installation costs.

Corrugated plates promote turbulence for high heat transfer efficiency.

Bolted frame allows easy disassembly and maintenance.

These features ensure reliable operation and long service life, even in the most challenging chemical environments.

HVAC and Energy Systems

Heating, ventilation, and air conditioning (HVAC) systems depend on stainless steel plate heat exchangers for efficient temperature regulation and energy recovery. These heat exchangers transfer thermal energy between hot and cold fluids without mixing, which helps reclaim heat from exhaust air and preheat incoming fresh air. This process reduces energy consumption and improves indoor air quality.

Plate heat exchangers are vital for heat recovery in HVAC systems.

They preheat fresh air using reclaimed heat, lowering energy use.

Advanced components maintain temperature regulation and improve energy utilization.

Compact design minimizes pressure drop, saving energy and reducing operational costs.

In district heating and cooling networks, these heat exchangers connect buildings to central systems, facilitating the transfer of hot or cold fluids. The HT-Bloc model from Shanghai Plate Heat Exchanger offers high efficiency and a small footprint, making it ideal for modern HVAC and energy systems.

Pharmaceutical Manufacturing

Pharmaceutical manufacturing demands strict hygiene, precise temperature control, and product purity. Stainless steel plate heat exchangers meet these requirements with sanitary-grade 316L stainless steel construction and polished surfaces that prevent microbial growth. Their design supports rigorous cleaning protocols and compliance with cGMP and FDA standards.

Feature | Description |

|---|---|

Material | Sanitary-grade 316L stainless steel for corrosion resistance and regulatory compliance. |

Design | Precision-engineered for efficient heat transfer and hygiene. |

Cleaning Protocols | Polished surfaces enable thorough cleaning and prevent contamination. |

Temperature Control | Accurate regulation protects sensitive pharmaceutical compounds. |

CIP/SIP Integration | Supports Clean-in-Place and Sterilize-in-Place systems. |

Validation and Testing | Ensures compliance with regulatory standards for product purity. |

Shanghai Plate Heat Exchanger’s HT-Bloc model provides reliable performance and easy maintenance, supporting the pharmaceutical industry’s focus on safety and quality.

Heat Exchangers in Steel Production

Steel production involves extreme temperatures and heavy-duty processes. Heat exchangers in steel production must withstand high thermal loads and corrosive environments. Stainless steel plate heat exchangers manage cooling and heat recovery tasks throughout the steelmaking process.

These heat exchangers cool hot gases, recover waste heat, and regulate temperatures in rolling mills and continuous casting lines. Their robust construction and efficient heat transfer help maintain stable operations and improve energy efficiency. The HT-Bloc welded plate heat exchanger from Shanghai Plate Heat Exchanger offers a compact, durable solution for steel production facilities.

Steel production plants benefit from:

Reliable cooling of process fluids and gases.

Enhanced energy recovery and reduced fuel consumption.

Long service life in harsh industrial environments.

Compact design that saves valuable space.

Steel production relies on these heat exchangers to optimize energy use and support sustainability goals.

Marine and Power Generation

Marine and power generation industries require robust thermal management solutions. Stainless steel plate heat exchangers play a critical role in cooling marine engines, regulating HVAC and refrigeration systems, and supporting desalination units. Their corrosion-resistant materials withstand harsh marine conditions and extend equipment lifespan.

Plate heat exchangers maintain optimal temperatures in marine engines.

They regulate HVAC, refrigeration, and desalination systems.

These systems enhance fuel efficiency and reduce emissions.

Stainless steel construction ensures durability in demanding environments.

In power generation, these heat exchangers recover waste heat from electricity production, improving efficiency and reducing fuel consumption. Shanghai Plate Heat Exchanger provides tailored solutions like the HT-Bloc model, which delivers reliable performance and supports energy efficiency in both marine and power sectors.

Stainless steel plate heat exchangers offer unmatched versatility and reliability across a wide range of industrial applications. Their role in energy recovery, process efficiency, and sustainability makes them indispensable in modern industry.

Real-World Examples and Selection Tips

Case Studies by Shanghai Plate Heat Exchanger

Industries rely on stainless steel plate heat exchanger technology to solve complex thermal management challenges. SHPHE’s HT-Bloc welded plate heat exchangers have demonstrated outstanding performance in several sectors:

Petrochemical plants use welded plate heat exchangers in crude oil preheat trains. These units reduce fouling and boost operational efficiency.

Chemical processing facilities report up to 30% improvement in thermal efficiency compared to traditional shell-and-tube designs.

Oil and gas companies benefit from reliable heat transfer and lower maintenance needs in high-pressure environments.

These examples show how advanced heat exchangers support productivity and energy savings.

Choosing the Right Model

Selecting the best heat exchanger for an industrial application requires careful consideration. Engineers evaluate several criteria:

Thermal conductivity ensures efficient heat transfer between fluids.

Corrosion resistance extends equipment life in harsh environments.

Mechanical properties provide structural integrity under stress.

Compatibility with fluids prevents damage from reactive substances.

Cleanability supports product quality and hygiene standards.

SHPHE offers expert guidance to help users match the right model to their process requirements.

Customization and Scalability

The modular design of HT-Bloc welded plate heat exchangers allows users to tailor solutions for specific needs. The table below highlights key features:

Feature | Description |

|---|---|

Standardized Modules | Interchangeable modules adapt to changing thermal requirements. |

Scalability | System capacity increases without major redesign. |

SHPHE’s flexible approach enables facilities to expand or modify their systems as production demands grow.

Stainless steel plate heat exchangers, such as the HT-Bloc from Shanghai Plate Heat Exchanger, deliver reliable thermal solutions for diverse industries. They offer reliable performance, long-term cost efficiency, and adaptability. The table below compares cost-effectiveness with other frames:

Aspect | Stainless Steel Frames | Carbon Steel Frames |

|---|---|---|

Initial Cost | Higher upfront cost | More economical option |

Durability | Excellent corrosion resistance and durability | Higher maintenance costs due to corrosion |

Long-term Cost Efficiency | Potentially lower due to extended service life | Higher due to frequent maintenance |

Installation Complexity | May have higher installation costs | Easier installation but may lack stability |

Operational Efficiency | Better flow distribution and thermal performance | May require more maintenance |

Industry experts recommend selecting the right design, performing regular maintenance, and utilizing innovative technologies for reliable results:

Recommendation | Description |

|---|---|

Select the right design and materials | Understand the application and operating conditions to choose appropriate materials, especially for corrosive fluids. |

Perform regular maintenance | Conduct routine inspections to identify fouling, leaks, or corrosion to maintain performance and minimize downtime. |

Utilize innovative technologies | Explore different plate patterns and configurations to enhance heat transfer efficiency and adapt to space constraints. |

SHPHE provides reliable thermal solutions that simplify industrial operations and support efficient, cost-effective performance.

FAQ

What makes stainless steel plate heat exchangers suitable for harsh environments?

Stainless steel resists corrosion and maintains strength. SHPHE’s HT-Bloc model uses high-quality materials for reliable performance in demanding industrial settings.

How often should a plate heat exchanger be cleaned?

Regular cleaning ensures optimal efficiency. SHPHE recommends scheduled inspections and cleaning based on fluid type and operating conditions.

Can the HT-Bloc welded plate heat exchanger be customized for different industries?

Yes. SHPHE offers modular designs and material options to meet specific requirements in food, chemical, energy, and marine applications.