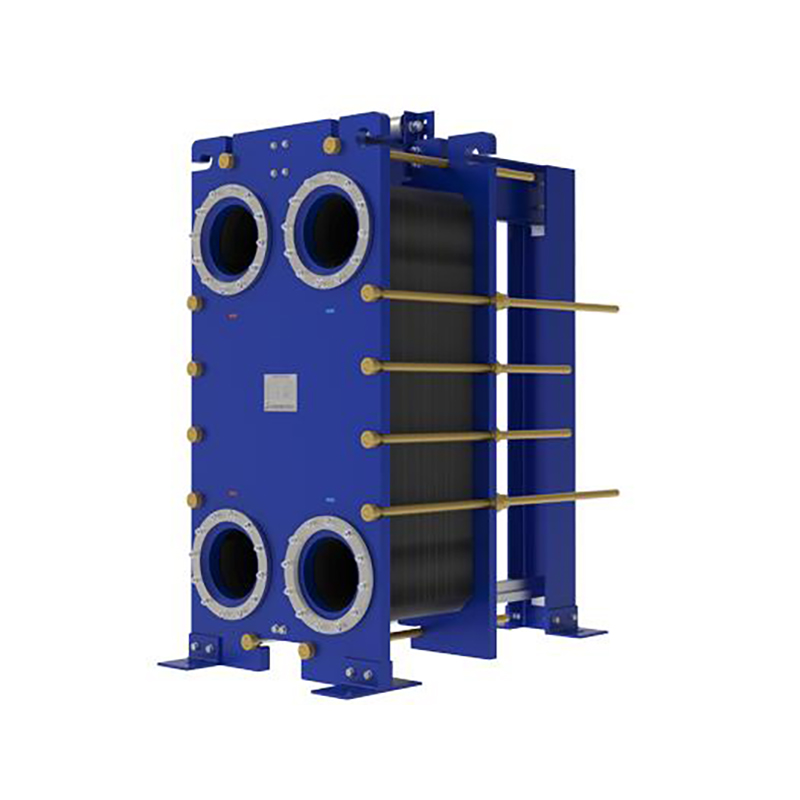

Frame plate heat exchanger picks for top efficiency

Compare top frame plate heat exchanger models for ...

More

The principle of steam condensers revolves around the phase change of steam back into water (condensate) after it has been used to perform work, such as driving a turbine. This process occurs within a closed system where exhaust steam is rapidly cooled, typically by circulating cold water through a network of tubes. The steam comes into contact with these cold surfaces, transferring its latent heat of vaporization to the cooling water. This heat transfer causes the steam to condense, creating a significant volume reduction. This reduction in volume, according to the ideal gas law, results in a very low pressure, almost a vacuum, within the condenser shell. This pressure differential between the turbine exhaust and the condenser is the primary driving force that pulls more steam through the turbine, significantly increasing the turbine's efficiency and power output. The basic types include surface condensers, where steam and cooling water are separated by heat transfer surfaces, and jet condensers, where steam and cooling water are directly mixed. Surface condensers are the predominant type in modern power generation due to their ability to recover pure condensate for reuse in the boiler system.

The operational principle is fundamental to the Rankine cycle, the thermodynamic cycle used in most steam power plants. In a surface condenser, the exhaust steam enters a large shell and is distributed over a bundle of thousands of tubes through which cool water, often from a cooling tower, lake, or river, is circulated. The latent heat from the steam is transferred through the tube walls to the cooling water, which becomes warmer. The now-condensed water (condensate) is collected in a hotwell located at the bottom of the condenser shell. A crucial component is the condensate extraction pump, which removes the condensate from this low-pressure environment and sends it back to the feedwater system for reheating in the boiler. The non-condensable gases (NCGs) like air that inevitably leak into the system are evacuated by steam jet ejectors or liquid ring vacuum pumps from a specific section of the condenser to maintain the deep vacuum. This entire process is not merely about cooling; it is about maximizing the enthalpy drop across the turbine. By maintaining the lowest possible turbine backpressure, the condenser allows for the maximum expansion of steam, extracting the most useful work. Data from power plant operations show that a change in condenser pressure of just 1 inch of mercury (inHg) can alter turbine heat rate and output by 1% or more, directly impacting fuel efficiency and megawatt generation. For a large 500 MW unit, this can represent a significant financial and operational impact, making condenser performance a key focus area for plant optimization.

The use of steam condensers is non-negotiable in thermal power generation and many industrial processes for compelling economic and thermodynamic reasons. The primary reason is to dramatically enhance the efficiency of the steam turbine system. By creating a vacuum at the turbine exhaust, the condenser maximizes the pressure drop across the turbine blades. This allows for a much greater expansion of steam, converting more of its thermal energy into mechanical work to spin the generator rotor. Without a condenser, the turbine would exhaust to the atmosphere at much higher pressure (0 psig instead of, for example, 1.5 psia), resulting in a drastically smaller pressure differential and a correspondingly massive loss in efficiency and power output. Historical data indicates that the adoption of condensers was a pivotal advancement, potentially improving the thermal efficiency of a steam cycle from less than 10% to over 30%. Secondly, condensers enable the closed-loop recycling of boiler feedwater. The condensate produced is hot, demineralized water that is ideal for returning to the boiler. This回收 saves immense costs on water treatment, chemical additives, and fresh water heating, directly reducing operational expenses. Furthermore, this practice is environmentally sustainable by minimizing water consumption and chemical discharge.

Beyond efficiency and resource recovery, condensers play a vital role in the overall stability and capacity of a power plant. A well-maintained condenser operating at its design vacuum allows a turbine to operate at its rated capacity. Conversely, fouled tubes or air ingress leading to high backpressure can force a derating of the turbine, meaning it cannot generate its full potential power, leading to lost revenue. Industry studies frequently cite condenser fouling as a leading cause of heat rate deterioration and capacity loss in power plants. For instance, a case study on a coal-fired plant showed that restoring condenser cleanliness recovered over 15 MW of lost capacity. Additionally, the condenser provides a central point for collecting exhaust steam from various auxiliary turbines and processes, simplifying the system architecture. It also collects non-condensable gases in one location for efficient extraction, protecting the system from corrosion caused by oxygen and CO2. The economic argument is overwhelming; the capital cost of a condenser is quickly offset by the substantial fuel savings and increased revenue from higher power output over the plant's lifespan, making it one of the most critical investments for any steam-based operation.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Compare top frame plate heat exchanger models for ...

More

Shanghai Heat Transfer stands out with its ISO9001...

More

Plate heat exchangers boost industrial energy effi...

More

Compare top steam heat exchanger suppliers and pro...

MoreHeat exchanger heating in HVAC systems boosts ener...

More

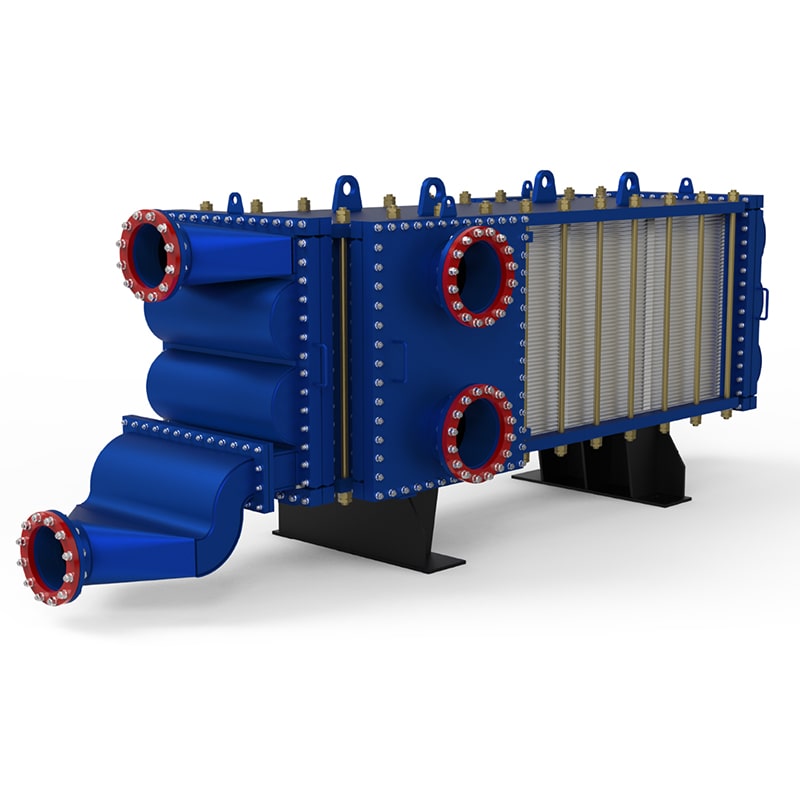

Gasketed plate heat exchangers boost industrial ef...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

James Wilson

Maintenance EngineerThese steam condensers are incredibly efficient and robust. We've seen a significant reduction in our energy consumption since installation. The build quality is exceptional and they've required minimal maintenance.

Sarah Chen

Plant ManagerReliable performance under high-pressure conditions. The heat transfer efficiency is impressive and has improved our overall system output. Delivery and installation were handled professionally.

Michael Rodriguez

HVAC TechnicianExcellent thermal efficiency and compact design. Perfect for our district heating system upgrade. The corrosion-resistant materials ensure long-term durability in our demanding environment.

Emily Foster

Process EngineerWell-designed condensers that integrate seamlessly with our existing steam system. The manufacturer's technical support was outstanding during the commissioning phase. A solid investment for any industrial operation.