Frame plate heat exchanger picks for top efficiency

Compare top frame plate heat exchanger models for ...

More

A steam to hot water heat exchanger is a critical piece of industrial equipment designed to transfer thermal energy from steam to a water-based system. It operates on the principle of indirect heating, where steam and water remain separate but thermal energy passes through a conductive barrier, typically a bundle of tubes or plates. This process efficiently raises the temperature of the water for various applications without direct mixing, ensuring a clean and controlled heat transfer. Common configurations include shell and tube, where steam often fills the shell and water flows through the tubes, and plate heat exchangers for more compact, efficient designs. These systems are fundamental in settings where steam, often generated by a boiler, is the primary energy source, but the end-use requires readily available hot water or a pressurized hot water loop. The precise engineering allows for the recovery and utilization of latent heat from steam condensation, maximizing energy efficiency. This technology is a cornerstone in sectors like manufacturing, food and beverage processing, chemical production, pharmaceutical manufacturing, and large-scale commercial and district heating systems, providing a reliable method to generate clean hot water for process needs, sanitation, or space heating.

The operational principle hinges on condensation. High-pressure steam enters the exchanger, releasing its latent heat as it comes into contact with the cooler surface of the heat transfer area. This causes the steam to condense into water (condensate), and the released thermal energy is absorbed by the water circulating on the opposite side. The temperature of the outgoing hot water is meticulously controlled by regulating the flow of steam into the exchanger, often via a temperature-controlled valve. The condensate is then typically returned to the boiler system to be reused, enhancing the overall system's efficiency and reducing water and chemical treatment costs. This closed-loop design is a hallmark of an optimized steam system. The design and selection of a steam to hot water heat exchanger depend heavily on factors such as required heat load (often measured in BTU/hr or kW), steam pressure and temperature, desired hot water temperature and flow rate, allowable pressure drops, and the specific properties of the fluids involved. Materials of construction, such as stainless steel tubes or plates, are selected based on the water quality and application to ensure longevity and prevent corrosion.

The implementation of a steam to hot water heat exchanger offers a multitude of significant advantages, making it a preferred solution for thermal fluid heating. The foremost benefit is exceptional energy efficiency. By harnessing the high latent heat of vaporization possessed by steam, these exchangers can transfer a large amount of energy in a relatively small unit. The ability to efficiently return condensate, which is still very hot, to the boiler reduces the energy required to generate new steam, leading to substantial fuel savings and a lower carbon footprint. Industry data and case studies frequently show a rapid return on investment (ROI) due to these energy savings, often paying for the equipment itself within a short operational period. Furthermore, the separation of fluids ensures that the quality of the generated hot water remains high and uncontaminated by boiler feed chemicals or corrosion products, which is a critical requirement for processes in food, beverage, and pharmaceutical industries.

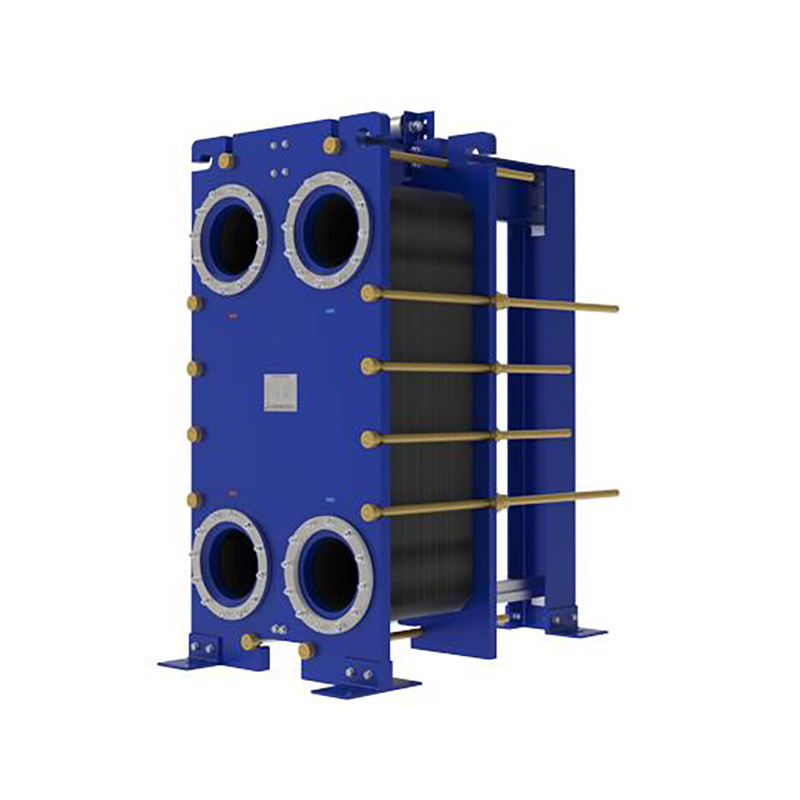

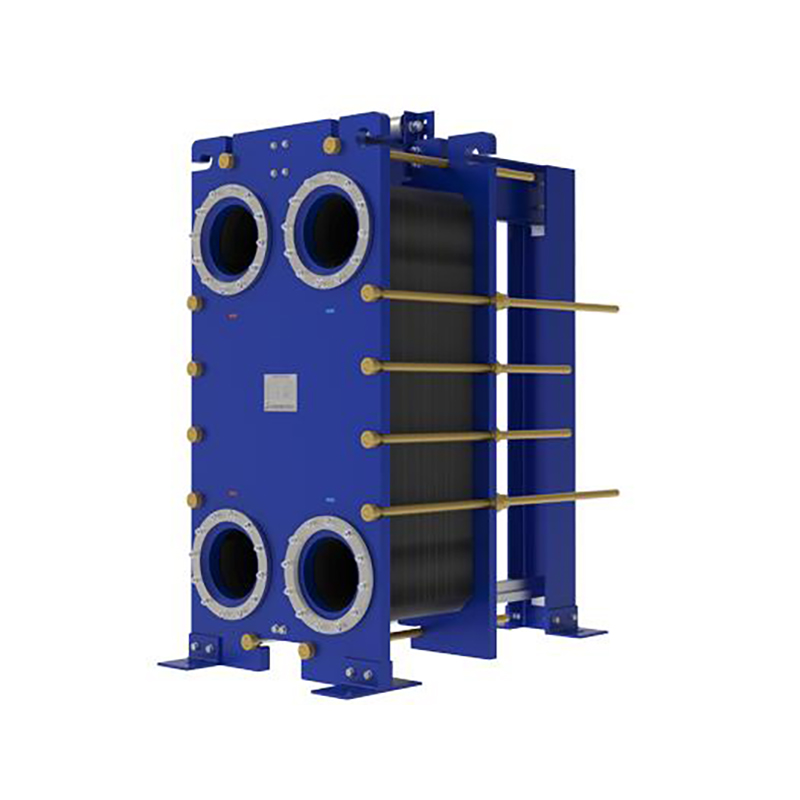

Another major advantage is operational reliability and a long service life. With no moving parts (in basic shell and tube designs), these heat exchangers are robust, require minimal maintenance, and offer consistent performance over decades. Their design allows for easy scalability; systems can be sized from small, skid-mounted units for a single building to massive custom-designed units for district heating networks serving entire communities. The precise temperature control achievable with a modulating steam valve ensures process stability and product quality in manufacturing applications. From a safety perspective, isolating the high-pressure steam system from the lower-pressure water system adds a layer of protection. Modern compact designs, like plate and frame heat exchangers, offer a high heat transfer coefficient, meaning they can achieve the same duty as a much larger shell and tube unit, saving valuable floor space. This combination of efficiency, reliability, safety, and compactness makes the steam to hot water heat exchanger an indispensable and economically sound asset in countless industrial and commercial heating applications.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Compare top frame plate heat exchanger models for ...

More

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

Shanghai Heat Transfer stands out with its ISO9001...

More

You can see clear differences between welded block...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Reynolds

Chief EngineerThis steam to hot water heat exchanger has been incredibly reliable for our hotel's heating system. The installation was straightforward, and it has significantly improved our energy efficiency. The build quality is exceptional.

Sarah Chen

Plant ManagerWe installed this unit in our food processing plant six months ago for sanitation and cleaning processes. It delivers consistent, high-temperature water on demand and has drastically reduced our steam consumption. A fantastic piece of equipment.

David Miller

Facility Operations ManagerA very robust and efficient heat exchanger. It perfectly handles the campus-wide heating load for our academic buildings. We deducted one star purely due to the lead time for delivery, but the product itself is top-notch.

Jessica Williams

HVAC Project EngineerAs a consulting engineer, I specify this model frequently for hospital retrofits. The thermal performance is excellent, it meets all pressure vessel codes, and my clients are always pleased with the low operating costs and quiet operation.