The Surprising Power of a Fully Welded Plate Heat Exchanger

Built for Extremes: Durability and Resistance

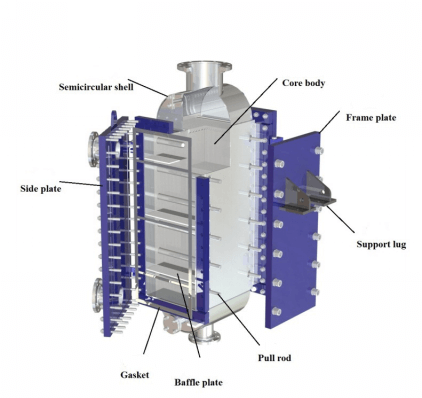

A fully welded plate heat exchanger is engineered to thrive in harsh industrial environments. Its robust construction provides exceptional durability and resistance against extreme operational demands.

Handling High-Pressure Operations

Traditional heat exchangers often fail under high pressure due to gasket limitations. Welded designs eliminate this weak point. The welded seams create a solid, contained unit capable of managing significantly higher pressures without the risk of gasket blowouts

| Heat Exchanger Type | Design Pressure (psig) | Design Pressure (barg) |

|---|---|---|

| Gasketed Plate & Frame | Up to 435 | Up to 30 |

| Welded Plate | Up to 1450 | Up to 100 |

Withstanding Temperature Extremes

Gaskets degrade at high temperatures, limiting the operational range of conventional units. A fully welded plate heat exchanger operates effectively at much higher temperatures because it has no gaskets. This makes it ideal for processes involving steam, hot oils, or other high-temperature fluids.

| Heat Exchanger Type | Maximum Operating Temperature |

|---|---|

| Gasketed Plate-and-Frame | 392°F (200°C) |

| Fully Welded Plate | 662°F (350°C) |

Ensuring Superior Material Integrity

Advanced welding techniques are central to the unit's strength. Methods like fusion and resistance welding create seamless, powerful connections between the plates. This process ensures a leak-proof design and provides outstanding structural soundness for long-term reliability.

Resisting Aggressive Corrosion

Operators can select from a wide range of corrosion-resistant materials for construction. This allows the heat exchanger to handle aggressive and hazardous fluids safely.

Available Materials Include:

Stainless Steel & Duplex Alloys

Titanium & Zirconium

Hastelloy & Nickel Alloys

Materials like Hastelloy offer excellent performance with acids, while high-grade stainless steels such as 254SMO provide superior resistance to chlorides. This material flexibility ensures optimal performance and equipment longevity.

Why a Fully Welded Plate Heat Exchanger Boosts Reliability

Operational reliability is a top priority in demanding industrial settings. A fully welded plate heat exchanger delivers superior performance by directly addressing the common failure points of traditional units, ensuring consistent and safe operation.

Eliminating Critical Leakage Risks

The primary source of leaks in conventional heat exchangers is gasket failure. Welded designs solve this problem at its root. The heat transfer plates are permanently joined with strong, seamless welds. This construction creates a hermetically sealed unit that completely eliminates the need for gaskets, thereby removing the most common leak paths. This design prevents both external leaks and internal cross-contamination between fluid streams.

Improving Plant and Personnel Safety

Fewer leaks directly translate to a safer work environment. Catastrophic gasket failures can release hazardous or high-temperature fluids, posing significant risks to personnel and equipment.

The robust, all-welded construction provides maximum safety and environmental protection. This design helps facilities comply with strict industry standards, including ASME and API protocols, especially in the chemical and oil & gas sectors.

Reducing Maintenance Requirements

A gasket-free design significantly simplifies maintenance schedules. Operators no longer need to budget for the regular inspection, replacement, and re-tightening of gaskets. This long-term reliability is proven in the field.

An oil-and-gas company has used welded units for over a decade to purify gas containing hazardous H2S, valuing their reliability and minimal maintenance.

A European refinery uses welded exchangers in its sulfur recovery unit, where special welding met stringent NACE codes for wet H2S service.

Minimizing Production Downtime

Reliable operation and low maintenance lead to one critical business advantage: greater uptime. Fewer unexpected failures and shorter planned service intervals keep production lines running smoothly. By preventing leaks and reducing service needs, this technology minimizes costly interruptions and maximizes plant productivity.

Compact Design, Maximum Efficiency

A key advantage of the fully welded plate heat exchanger is its ability to deliver maximum thermal performance within a minimal physical space. This efficiency stems from an intelligent design that outperforms older, bulkier technologies.

High Heat Transfer in a Small Footprint

The unit's high efficiency originates from its corrugated plates. These plates create complex channels that force fluids into a turbulent flow. This turbulence maximizes heat transfer across the plate surface.

Special corrugation patterns induce high turbulence even at low flow rates.

This design increases wall shear stress, which enhances heat transfer coefficients.

Advanced distribution areas like the CurveFlow design ensure fluid spreads evenly, improving overall efficiency by up to 15%.

This turbulent flow allows the unit to achieve the same heat duty with a much smaller surface area compared to other designs.

A Space-Saving Alternative to Shell-and-Tube

This technology offers a compact solution for industrial facilities. A fully welded plate heat exchanger typically requires 50-80% less floor space than a shell-and-tube unit performing the same task. This reduction is especially critical in applications with limited room, such as offshore platforms.

A proposed multi-stream arrangement for an offshore platform demonstrated a significant reduction in required heat exchanger area, highlighting the technology's value in space-constrained environments.

| Heat Exchanger Type | Total Heat Exchanger Area (m²) |

|---|---|

| Conventional Shell and Tube | 9350.96 |

| Multi-stream Arrangement | 3598 |

Optimizing Thermal Performance

Engineers use advanced tools to perfect thermal efficiency. Computational Fluid Dynamics (CFD) is essential for this process. CFD analysis allows designers to simulate fluid flow and heat transfer inside the exchanger. They can test different plate patterns, angles, and spacing digitally. This virtual prototyping helps identify the most effective configuration, leading to designs with up to 25% higher thermal efficiency than conventional models. This optimization ensures every unit delivers peak performance.

Key Industrial Applications and Use Cases

The robust and efficient design of welded plate heat exchangers makes them a superior choice across many demanding industries. Their reliability and performance solve critical challenges in complex processes.

Oil and Gas Refining

In oil and gas operations, these units are essential for maximizing efficiency and safety. They perform critical duties throughout the refining process, from crude oil distillation to cooling final products.

·Key Roles: Preheaters, re-boilers, condensers, and economizers.

·Economic Benefits: Their compact size reduces installation space, while high heat recovery lowers energy consumption. This leads to a minimized total annual cost.

Chemical and Petrochemical Processing

Chemical plants rely on precise thermal management for process stability. Welded exchangers provide the necessary temperature control for sensitive reactions, especially in polymer and plastics production. They optimize energy recovery and minimize fouling, which helps plants increase throughput and reliability in creating ethylene, polymers, and other aromatics.

Power Generation and HVAC Systems

These heat exchangers are vital in modern power generation.

In nuclear facilities, their leak-proof, welded construction safely handles critical fluids in auxiliary systems. They are built to withstand high pressures and radiation.

In geothermal plants, they efficiently transfer heat from the earth to a working fluid, which then generates electricity with minimal environmental impact.

Pharmaceutical and Sanitary Processes

High purity is non-negotiable in pharmaceutical and sanitary applications. The gasket-free, hermetically sealed design of a fully welded plate heat exchanger prevents cross-contamination between fluid streams. This ensures the integrity of sensitive products while providing the precise temperature control needed for consistent quality.

A fully welded plate heat exchanger provides exceptional durability for extreme industrial duties. Its gasket-free, leak-proof design ensures superior operational reliability and safety. This technology combines robust, low-maintenance construction with high thermal efficiency in a compact footprint, representing a superior engineering solution for challenging heat transfer applications.

FAQ

What makes a fully welded unit different?

A fully welded unit has no gaskets. Its plates are welded together, creating a stronger, leak-proof design. This allows it to handle higher pressures and temperatures safely.

Can it be used with any type of fluid?

Yes, it can. Engineers select from various corrosion-resistant materials like stainless steel or titanium. This customization ensures safe, long-term performance with aggressive or hazardous industrial fluids.

Is cleaning a fully welded unit difficult?

Cleaning is straightforward. Operators use a Cleaning-In-Place (CIP) system. This process circulates cleaning solutions through the unit, effectively removing fouling without needing to disassemble the heat exchanger.