The Ultimate 2025 Guide What Are Heat Exchanger Gaskets?

Core Functions of Heat Exchanger Gaskets

Heat exchanger gaskets perform several essential jobs that are vital for the overall performance and safety of industrial systems. They are more than simple seals; they are engineered components that enable precise process control. Understanding these core functions highlights their importance in modern industry.

Sealing and Leak Prevention

The most fundamental function of a gasket is to create a robust seal. This seal prevents the process fluids from leaking out of the heat exchanger unit. A leak can lead to lost product, environmental hazards, and costly downtime. Gasket failures are a primary source of these leaks.

Common causes of gasket failure include:

·Material Aging: Gaskets lose elasticity over time from exposure to high temperatures and corrosive fluids.

·Improper Installation: Incorrect placement or uneven bolt tightening compromises the seal's integrity.

·Exceeding Design Conditions: Sudden pressure spikes or temperature surges can push a gasket beyond its limits, causing displacement and failure.

·Frequent System Cycles: Repeated startups, shutdowns, and temperature changes accelerate material fatigue.

Pro Tip: Aging of sealing gaskets is a frequent cause of leakage, especially at flanged connections. Regular inspection and replacement are key to preventing unexpected failures.

Maintaining System Pressure

Industrial processes often operate under specific, and sometimes extreme, pressures. Gaskets must withstand these forces to keep the system stable and efficient. The gasket material and design directly influence its ability to handle high pressure and thermal cycling.

For example, certain gasket styles are engineered specifically for demanding conditions:

·Solid Flat Metal Gaskets: These metal-only seals are ideal for high-pressure applications but require very smooth flange surfaces.

·Corrugated Kammprofile Gaskets: A corrugated metal core combined with a soft facing material gives these gaskets excellent performance. They can withstand high stress and are effective in systems with frequent temperature fluctuations.

Properly selected heat exchanger gaskets ensure the system maintains its target operating pressure, preventing performance loss and potential safety risks.

Optimizing Thermal Efficiency

While their main job is sealing, gaskets also play a role in the thermal performance of a plate heat exchanger. The gasket ensures that the plates are held at the correct distance, which optimizes the flow turbulence and heat transfer rate. An incorrect or degraded gasket can compromise this spacing, reducing efficiency.

Innovations in material science are further enhancing this function.

·Researchers are exploring nanocomposite gaskets with higher thermal conductivity to improve heat transfer directly through the gasket material.

·In a real-world example, a pharmaceutical plant upgraded to specialized GYLON BIO-PRO® sanitary gaskets. This change not only reduced leaks but also improved overall system efficiency and simplified inventory.

This shows that the right gasket selection contributes directly to energy savings and better operational output.

Ensuring Fluid Separation

In a plate heat exchanger, two different fluids flow on opposite sides of the plates to transfer heat without mixing. The gasket's job is to create a dual-seal system that keeps these fluid streams completely separate. One seal directs the fluid across the plate, while the second seal prevents it from leaking externally.

This separation is critical in many industries:

·Food and Beverage: Prevents cross-contamination between a product (like milk) and a heating/cooling medium (like water).

·Chemical Processing: Keeps reactive chemicals from mixing, which could cause dangerous reactions.

·HVAC and Power Generation: Ensures fluids like coolants and lubricants remain in their designated circuits.

By maintaining two distinct flow channels, heat exchanger gaskets protect product quality, ensure process safety, and uphold the thermal efficiency of the unit.

Key Advantages in Industrial Applications

Heat exchanger gaskets provide significant advantages across various industrial settings. Their design and material composition directly contribute to system efficiency, safety, and longevity. These benefits make them indispensable components in modern process industries.

Adaptability and Material Versatility

Gaskets offer incredible adaptability due to the wide range of available materials. This versatility allows engineers to select the perfect gasket for specific operating conditions, including temperature, pressure, and chemical exposure. Different materials provide unique properties, making them suitable for diverse industries from food processing to chemical manufacturing.

Common gasket materials include:

·Nitrile (NBR): Resists petroleum-based oils and fuels. It is a common choice for applications involving hydrocarbons.

·EPDM: Offers excellent resistance to weathering, hot water, and steam. It is often used in general sealing and HVAC systems.

·Viton® (FKM): Provides outstanding resistance to high temperatures and aggressive chemicals. It is ideal for extreme operating conditions.

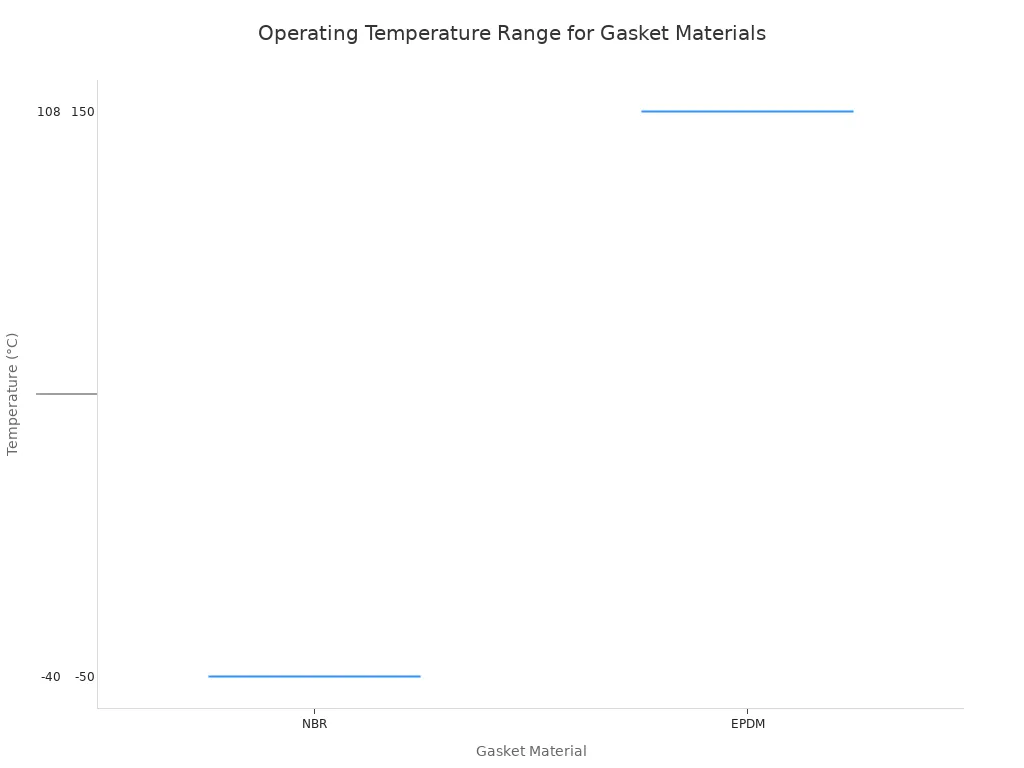

The operating temperature and chemical resistance of these materials vary significantly.

| Material | Operating Temperature Range | Chemical Resistance Highlights |

|---|---|---|

| NBR (Nitrile Rubber) | -40°C to +108°C | Excellent resistance to petroleum-based oils and fuels. Poor resistance to UV and hot water. |

| EPDM | -50°C to +150°C | Excellent resistance to hot water, steam, and weathering. Poor resistance to oils and fuels. |

| Viton® (FKM) | -20°C to +200°C | Outstanding resistance to chemicals, solvents, and high temperatures. |

For sensitive applications like food, beverage, and pharmaceutical production, specific materials receive FDA approval. These include food-grade EPDM, Nitrile, Silicone, and PTFE, which prevent contamination and ensure product safety.

Cost-Effectiveness and Maintenance

Gaskets are central to the cost-effective maintenance of plate heat exchangers. Unlike shell-and-tube exchangers, plate units are easy to disassemble. Maintenance teams can access heat transfer surfaces by simply removing the tightening bolts. This design simplifies cleaning and inspection, reducing downtime and labor costs.

Maintenance Insight: A plate heat exchanger can be opened, cleaned, and put back online quickly. This process avoids the need for heavy equipment like cranes or the week-long delays associated with cleaning shell-and-tube units.

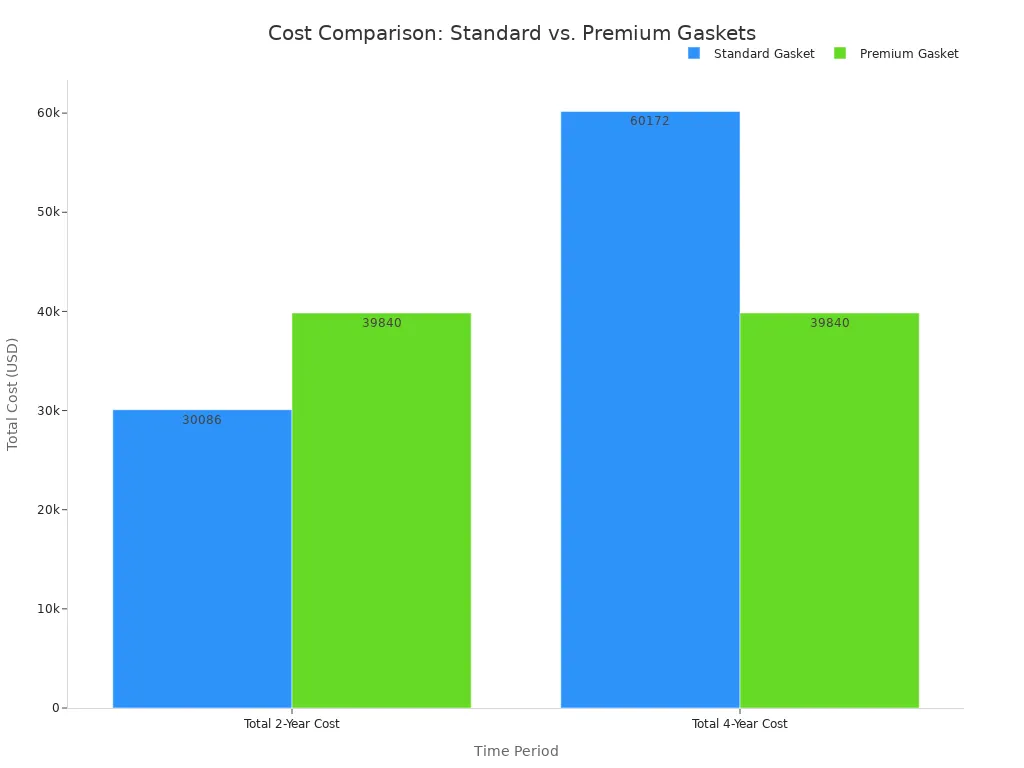

Choosing a premium gasket over a standard one also delivers significant long-term savings. While premium gaskets have a higher initial purchase price, their extended service life reduces replacement frequency. This minimizes labor costs and production losses over time. A four-year cost analysis shows that premium gaskets can save over $20,000 compared to standard ones that require replacement.

Regular inspections are key to maximizing gasket life and preventing costly failures. Annual checks for elasticity and damage are recommended, with full replacement typically occurring every 3 to 5 years under normal conditions.

Enhanced Operational Safety

Proper gasket selection and installation are critical for operational safety. Gasket integrity directly supports compliance with safety regulations, such as OSHA's Process Safety Management (PSM) standard. This standard mandates mechanical integrity programs to prevent the uncontrolled release of hazardous chemicals.

A robust mechanical integrity program includes:

1.Proper Identification: Identifying all critical equipment, including heat exchangers.

2.Regular Inspections: Performing scheduled tests and inspections.

3.Correct Procedures: Following established maintenance and installation procedures.

4.Quality Assurance: Verifying the use of appropriate materials, including the correct gaskets, bolts, and torque specifications.

A failed gasket can be the primary point of failure leading to a chemical release. Ensuring the correct gasket material is used and installed properly is a fundamental line of defense. This protects personnel, prevents environmental damage, and avoids catastrophic equipment failure.

Improved System Reliability

The reliability of a heat exchanger depends heavily on the performance of its gaskets. A high-quality gasket maintains a perfect seal, which ensures stable system pressure and optimal thermal performance. Key performance indicators (KPIs) like pressure drop and the fouling factor are directly influenced by gasket condition. A degrading gasket can cause internal leaks, leading to increased pressure drop and reduced efficiency.

The lifespan of heat exchanger gaskets typically ranges from three to ten years. However, this can shorten significantly in aggressive environments. For example, operating a rubber gasket just 10°C above its maximum recommended temperature can cut its average lifespan in half.

Maintenance teams should monitor for signs of aging and degradation to prevent unexpected failures.

·Visible Damage: Look for cracks, fraying, or deformation.

·Fluid Leakage: Puddles or drips around the unit are a clear sign of a failing seal.

·Performance Loss: A sudden drop in efficiency or an increase in energy consumption can indicate an internal leak.

·Unusual Noises: Hissing sounds often point to fluid or air escaping through a compromised seal.

Proactive monitoring and timely replacement of aging gaskets are essential practices for maintaining high system reliability and preventing costly, unplanned downtime.

Heat exchanger gaskets are fundamental components for safe and reliable industrial operations. Recognizing their core functions is key to optimizing system performance and making informed maintenance decisions. Proper material selection and management directly contribute to operational longevity and significant cost savings, reflecting a growing industry focus on durability.

FAQ

How often should gaskets be replaced?

Gaskets typically require replacement every 3 to 5 years. Aggressive operating conditions and specific materials can alter this schedule. Regular inspections help determine the exact timing for replacement.

Can you reuse a heat exchanger gasket?

Experts advise against reusing gaskets. A compressed gasket loses its original sealing properties. Reusing it risks leaks, poor performance, and potential system damage, compromising operational integrity.

What causes a gasket to fail?

Common causes include material aging, incorrect installation, and exceeding design limits for temperature or pressure. Each factor compromises the gasket's ability to maintain a secure seal.