Top Gasket Free Heat Exchanger Models for Industrial Use

Shanghai Heat Transfer’s HT-Bloc Welded Plate Heat Exchanger leads the list of top manufacturers in the gasket free heat exchanger market for 2026, joined by renowned names like Alfa Laval, Kelvion, Danfoss, GEA, SWEP, and Tranter. Selecting the right model ensures optimal efficiency, consistent reliability, and cost-effectiveness in demanding industrial environments. Industrial engineers focus on criteria such as material durability, corrosion resistance, maintenance needs, and adaptability to harsh operating conditions. Shanghai Heat Transfer stands out as an innovator, delivering advanced solutions for modern industry.

Top Gasket Free Heat Exchanger Models

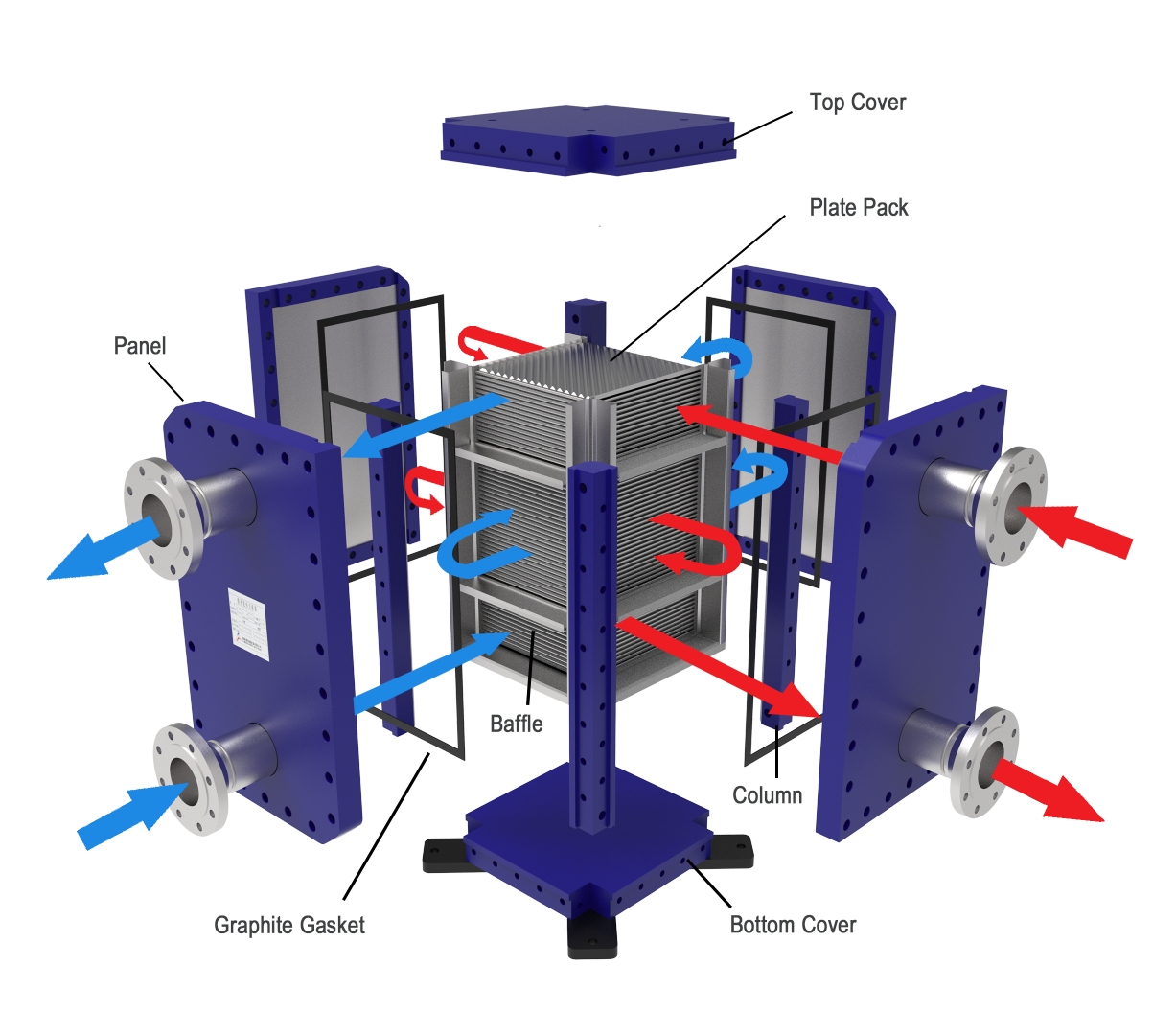

Shanghai Heat Transfer HT-Bloc Welded Plate

Shanghai Heat Transfer’s HT-Bloc Welded Plate Heat Exchanger stands at the forefront of the global plate heat exchangers market. This model features a fully welded design without gaskets, which ensures leak-free operation in high-pressure and high-temperature environments. The compact structure and modular architecture allow for easy customization and scalability, making it suitable for a wide range of industries. The HT-Bloc minimizes fouling due to high turbulence and reduces installation costs, setting a new standard for advanced plate heat exchangers. Its robust construction from stainless steel, titanium, or Hastelloy guarantees long-term durability. Industrial sectors such as oil refining, chemical processing, metallurgy, power generation, pulp and paper, coke production, and sugar production rely on this solution for efficient and reliable thermal management.

Key Features and Applications of HT-Bloc Welded Plate Heat Exchanger:

Unique Selling Points | Industrial Applications |

|---|---|

Fully welded design without gaskets | Oil refining |

High-pressure and high-temperature tolerance | Chemical processing |

Easy disassembly for maintenance | Metallurgy |

High heat transfer efficiency | Power generation |

Compact structure with small footprint | Pulp and paper |

Minimizes fouling due to high turbulence | Coke production |

Reduces installation costs | Sugar production |

Alfa Laval Compabloc

Alfa Laval Compabloc has earned a strong reputation in the global plate heat exchangers market for its innovative technology and reliability. The Compabloc model incorporates SmartClean™, which allows for full cleaning of plates and enhances maintenance efficiency. The +Seal feature introduces a fully confined graphite gasket, preventing leaks even at high pressures and simplifying maintenance routines. XCore™ technology increases mechanical strength, supporting high-pressure applications without compromising performance. The C-Weld laser welding technique eliminates dead zones, improving reliability and serviceability. These advanced plate heat exchangers serve industries such as oil and gas, chemicals, and power generation, where uptime and safety are critical.

SmartClean™ enables efficient cleaning and reduces fouling.

+Seal prevents leaks and simplifies maintenance.

XCore™ provides superior mechanical strength for demanding applications.

Kelvion Welded Plate Series

Kelvion’s Welded Plate Series delivers exceptional durability and minimal maintenance requirements. These advanced plate heat exchangers use hermetically sealed TIG welding seams, which minimize leaks and enhance operational life. The design withstands extreme temperatures and thermal shock, reducing the risk of unplanned downtime. Maintenance remains minimal due to the absence of gaskets, which simplifies upkeep and lowers service costs. The Kelvion K°Bloc model, in particular, excels in handling high temperatures, pressures, and corrosive fluids. Industries such as chemical processing, power generation, and heavy manufacturing benefit from these gasket-free welded plate assemblies.

Danfoss Gasket Free Solutions

Danfoss offers a comprehensive range of gasket free heat exchanger solutions, including brazed plate heat exchangers that have become a staple in the global plate heat exchangers market. These models provide compact and flexible solutions for high-pressure or extreme-temperature applications. Danfoss designs focus on ultra-efficient performance, resulting in low operational costs and reliable operation during temperature swings. Customization options include copper, CoResist, or stainless steel with various plate technologies. The Micro Plate™ technology delivers next-generation efficiency, making these units ideal for district energy solutions, heat pumps, and chillers.

Feature | Description |

|---|---|

Brazed Plate Heat Exchangers | Compact and flexible solution for high-pressure or extreme-temperature applications. |

Low Operational Costs | Designed for ultra-efficient performance, optimal for systems with temperature swings. |

Customization Options | Available in copper, CoResist, or stainless steel with various plate technologies. |

Micro Plate™ Technology | Next-generation efficiency, ideal for district energy, heat pumps, and chillers. |

Danfoss brazed plate heat exchangers serve a wide range of industries, including cold chain, air conditioning, process cooling, hydronic heating, district energy, marine, dairy, food and beverage, sugar, biogas, pulp and paper, heavy industry, mining, petrochemical, and chemical sectors.

GEA BlocWeld

GEA BlocWeld stands out in the global plate heat exchangers market for its focus on safety and leak prevention. The hermetically sealed construction, achieved through TIG welding without filler metals, significantly reduces the risk of leaks. This design resists damage from chemicals and extreme temperatures, making it a safer option compared to traditional models that rely on gaskets. GEA BlocWeld advanced plate heat exchangers are widely used in chemical processing, power generation, and other industries where safety and reliability are paramount.

SWEP All-Welded Range

SWEP’s All-Welded Range has gained traction in the global plate heat exchangers market, especially in industries that demand robust performance and leak-free operation. These brazed plate heat exchangers operate reliably in harsh environments, eliminating leakage risks. The oil and gas sector values their robustness, while power generation facilities rely on their ability to handle high pressures and temperatures. SWEP’s all-welded models deliver operational benefits such as reduced maintenance and increased uptime, making them a preferred choice for demanding industrial applications.

Industry | Operational Benefits |

|---|---|

Oil & Gas | Robustness, ability to operate in harsh environments, elimination of leakage risks. |

Power Generation | Designed to handle high pressures and temperatures, suitable for demanding applications. |

Tranter Welded Plate Series

Tranter’s Welded Plate Series offers a versatile solution for industries seeking reliable gasket free heat exchanger technology. These brazed plate heat exchangers feature a fully welded design that ensures leak-free operation and high thermal efficiency. Tranter models support a variety of fluids and process conditions, making them suitable for chemical processing, oil and gas, and power generation. Their compact footprint and robust construction help reduce installation costs and maximize plant efficiency.

The global plate heat exchangers market continues to evolve, with each of these models setting new benchmarks for efficiency, safety, and adaptability. Shanghai Heat Transfer’s HT-Bloc Welded Plate Heat Exchanger remains a standout choice for industries seeking advanced plate heat exchangers that deliver unmatched reliability and performance.

Comparison Table

Key Specifications

The top gasket free heat exchanger models offer advanced engineering and robust performance. Each model features unique specifications that address the demands of the global plate heat exchangers market. The following table summarizes the main technical details:

Model | Materials | Pressure Rating | Temperature Range | Efficiency | Modularity |

|---|---|---|---|---|---|

Stainless steel, titanium, Hastelloy | Up to 40 bar | Up to 400°C | High | Modular, scalable | |

Alfa Laval Compabloc | Stainless steel, titanium | Up to 30 bar | Up to 350°C | High | Flexible modules |

Kelvion Welded Plate Series | Stainless steel, nickel alloys | Up to 25 bar | Up to 300°C | High | Customizable units |

Danfoss Gasket Free Solutions | Copper, stainless steel | Up to 30 bar | Up to 200°C | Ultra-high | Compact designs |

GEA BlocWeld | Stainless steel | Up to 25 bar | Up to 300°C | High | Modular blocks |

SWEP All-Welded Range | Stainless steel, copper | Up to 30 bar | Up to 200°C | High | Space-saving units |

Tranter Welded Plate Series | Stainless steel, titanium | Up to 25 bar | Up to 300°C | High | Modular, compact |

Note: Pressure and temperature ratings may vary based on specific configurations and industry requirements.

Features and Applications

Manufacturers design these heat exchangers to meet the evolving needs of the global plate heat exchangers market. Each model excels in different environments and supports a wide range of industrial processes. The following list highlights the industries and applications best suited for these top models:

Refrigeration plants

Engine cooling operations

Dairy and food production

Chemical processing facilities

Oil production sites

Power generation plants

Shanghai Heat Transfer’s HT-Bloc Welded Plate Heat Exchanger demonstrates exceptional adaptability in power generation, metallurgy, and offshore applications. Alfa Laval Compabloc and Kelvion Welded Plate Series serve chemical processing and heavy manufacturing. Danfoss Gasket Free Solutions provide reliable performance in HVAC, refrigeration, and district energy. GEA BlocWeld and SWEP All-Welded Range deliver robust operation in oil production and power generation. Tranter Welded Plate Series supports chemical, oil, and energy sectors. The global plate heat exchangers market continues to expand as industries seek efficient, durable, and modular solutions for thermal management.

Performance and Reliability

Efficiency and Heat Transfer

Industrial engineers value high efficiency in every gasket free heat exchanger. These models deliver superior heat transfer rates, which help companies reduce energy consumption and operating costs. Many studies show that spiral plate heat exchangers outperform conventional designs. They achieve improved heat transfer by optimizing flow patterns and turbulence.

Computational fluid dynamics tools reveal that an optimal Reynolds number of 5,000 maximizes heat exchange and minimizes pressure drop.

Increased gas velocity and solid mass flux boost heat exchange rates, especially with smaller particles and larger bed heights.

Manufacturers in the global plate heat exchangers market focus on high efficiency to meet strict industry standards. High efficiency supports energy efficiency goals and helps facilities maintain stable operations.

Durability and Maintenance

Durability remains a top priority for industrial users. Gasket free heat exchangers use welded or brazed construction, which eliminates the risk of gasket failure. This design choice extends service life and reduces unplanned downtime. The following table compares maintenance challenges and advantages for different types of heat exchangers:

Type of Heat Exchanger | Maintenance Challenges | Advantages |

|---|---|---|

Gasket Plate Heat Exchangers | Requires frequent maintenance to prevent leaks | Easier to disassemble for cleaning and gasket replacement |

Brazed Plate Heat Exchangers | Challenges in cleaning or repairing internal surfaces | Generally maintenance-free |

Operators choose welded plate models for their minimal maintenance needs. These units resist corrosion and fouling, which further improves reliability in harsh environments.

Safety and Leak Prevention

Safety plays a critical role in industrial heat exchanger selection. Gasket free heat exchangers provide leak-resistant performance, even under high pressure and temperature. Welded designs prevent leaks that could lead to costly shutdowns or safety incidents. Many industries trust these models to protect workers and equipment. High efficiency and robust construction combine to deliver reliable, safe operation in demanding applications.

Gasket Free Heat Exchanger Selection Guide

Assessing Industrial Needs

Selecting the right gasket free heat exchanger starts with a clear understanding of industrial requirements. Each facility faces unique challenges, from the type of media being transferred to the operating temperature and pressure. The following table outlines key factors to consider during the assessment process:

Factor | Description |

|---|---|

Gasket Material Selection | Choosing the right material ensures durability and compatibility with the operating environment. |

Installation Practices | Proper installation prevents leaks and supports a reliable seal. |

Inspection Protocols | Regular inspections help identify wear and prevent failures. |

Compliance with Standards | Adhering to regulations ensures safety and optimal performance. |

Facilities should also evaluate the size and condition of joint components, the required sealing load, and the presence of vibration or rapid temperature changes.

Matching Features to Applications

The global plate heat exchangers market offers a wide range of models, each designed for specific industrial needs. Engineers should match features to applications by considering:

The type of media and its corrosiveness

Required pressure and temperature ratings

Space constraints and installation footprint

Maintenance accessibility

For example, U-tube designs manage thermal expansion well, while removable partition plates allow for easier maintenance in power generation and chemical processing. Non-removable bundles suit high-pressure applications where leakage prevention is critical.

Cost and Ownership

Cost considerations extend beyond the initial purchase. The total cost of ownership includes maintenance, downtime, and operational efficiency. Shell and tube heat exchangers often provide lower long-term costs in fouling services due to their durability. Plate heat exchangers may offer lower upfront costs, but frequent repairs in harsh environments can increase expenses over time. Selecting the right model helps avoid unexpected costs and inefficiencies.

Why Choose Shanghai Heat Transfer

Shanghai Heat Transfer stands out in the global plate heat exchangers market for its innovative HT-Bloc Welded Plate Heat Exchanger. This model delivers exceptional reliability, modularity, and efficiency. Its robust construction and advanced design meet the demands of industries such as power, offshore, and metallurgy. Companies seeking a dependable gasket free heat exchanger benefit from Shanghai Heat Transfer’s commitment to quality and tailored solutions.

Industrial leaders continue to rely on top gasket free heat exchanger models, including Shanghai Heat Transfer’s HT-Bloc, Alfa Laval Compabloc, and others. Selecting the right model ensures reliable performance and efficiency in every application. Shanghai Heat Transfer’s HT-Bloc stands out for its modular design and robust construction.

Experts recommend consulting manufacturers for tailored solutions. Key benefits include:

Wider channel designs that reduce blockage and simplify cleaning

Continuous maintenance and precise monitoring for efficient operation

Automatic self-cleaning systems that lower manual maintenance costs

FAQ

What is a gasket free heat exchanger?

A gasket free heat exchanger uses welded or brazed joints instead of gaskets. This design prevents leaks and withstands high pressure and temperature. Many industries prefer this type for reliability and minimal maintenance.

Why do industries choose welded plate heat exchangers?

Industries select welded plate heat exchangers for their durability and efficiency. These units handle aggressive fluids and extreme conditions. They also reduce downtime and maintenance costs.

How does modularity benefit industrial applications?

Modularity allows engineers to customize and scale heat exchangers. Facilities can add or remove modules to match process changes. This flexibility supports future expansion and system upgrades.

Which industries use Shanghai Heat Transfer’s HT-Bloc model?

Industry | Application Example |

|---|---|

Power | Steam cycle optimization |

Offshore | Marine cooling systems |

Metallurgy | Slurry and ore processing |

HT-Bloc adapts to many demanding environments.