Top Reasons to Pick Plate and Frame Heat Exchangers Over Shell and Tube

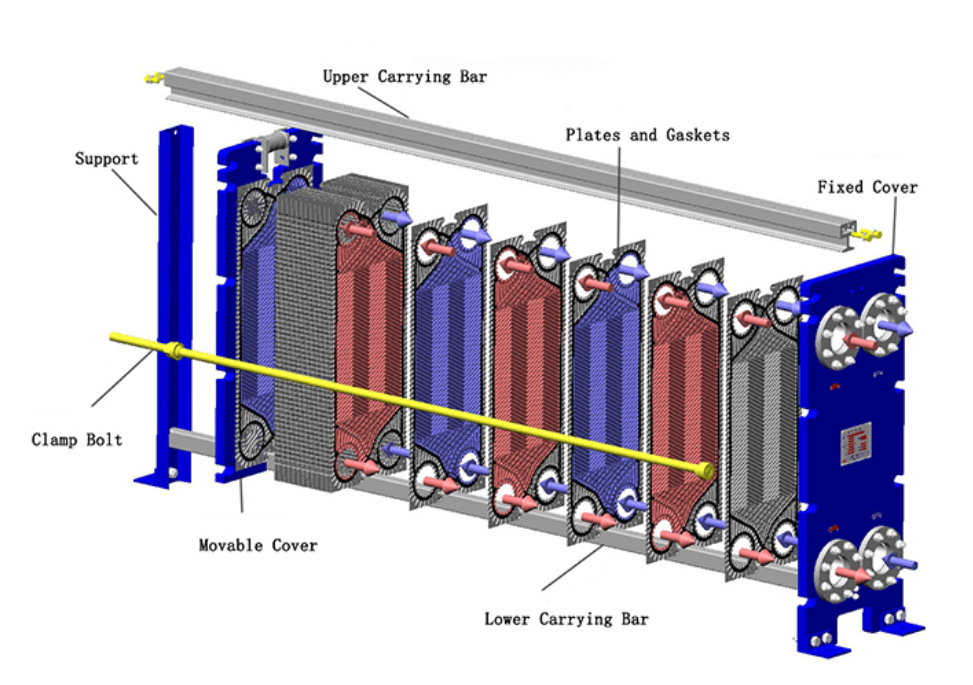

Plate and frame heat exchangers, especially the Gasketed Plate Heat Exchanger from Shanghai Heat Transfer, often deliver better results than a shell and tube heat exchanger. Engineers choose these units for their compact footprint, quick cleaning, consistent operation, cost savings, flexible expansion, and lower pressure drop. Facilities benefit from easy installation and reliable compliance with safety standards.

Efficiency of Plate and Frame Heat Exchanger

Superior Heat Transfer

Shanghai Heat Transfer’s Gasketed Plate Heat Exchanger stands out for its remarkable heat transfer efficiency. The design uses corrugated plates to create a large surface area, which boosts the overall heat transfer coefficient. This model achieves values up to 7,000 W/m²·K, far higher than most shell and tube units. The plate and frame heat exchanger also offers a surface-area density between 100 and 200 m²/m³, making it ideal for facilities that need powerful performance in a compact space.

The following table compares heat transfer efficiency between plate and frame and shell and tube heat exchangers:

Heat Exchanger Type | Heat Transfer Efficiency |

|---|---|

Plate and Frame | Transfers heat five times more efficiently than shell-and-tube |

Shell and Tube | Lower yield output compared to plate-and-frame |

This high efficiency leads to better energy recovery and supports sustainability goals. Facilities can recover more heat from processes, which reduces energy waste and lowers operating costs.

Close Temperature Approach

A plate and frame heat exchanger can achieve a close temperature approach, meaning the temperature difference between the hot and cold fluids is very small. This feature allows for precise control and maximizes heat exchanger efficiency.

Heat Exchanger Type | Average Temperature Approach |

|---|---|

Plate Heat Exchanger | |

Shell and Tube Heat Exchanger | 5 °C or more |

The ability to reach a temperature approach as low as 1 °C means that the overall heat transfer coefficient remains high, even in demanding applications. This performance makes Shanghai Heat Transfer’s Gasketed Plate Heat Exchanger a top choice for industries that value energy savings and process optimization.

Cooling systems use plate and frame heat exchangers to keep equipment safe and running smoothly.

Waste heat recovery becomes easier, helping companies conserve energy.

Heat recovery from flue gases cuts down on greenhouse gas emissions.

These units work well for both heating and cooling, adapting to different industrial needs.

Easy Maintenance

Quick Cleaning

Shanghai Heat Transfer’s Gasketed Plate Heat Exchanger features a gasketed design that makes cleaning simple and fast. The plates can be separated easily, allowing for thorough cleaning without complicated tools. Many facilities choose this model because it supports Clean-in-Place (CIP) systems. CIP lets operators clean the unit without taking it apart. This process saves time and ensures every surface gets cleaned, even in hard-to-reach areas.

CIP allows cleaning without disassembly, making it faster.

It is more efficient than manual cleaning methods that require disassembly.

The cleaning solution can reach all areas, ensuring thorough cleaning and removal of stubborn fouling.

The low fouling nature of the plate design also means less buildup over time. As a result, operators spend less time on heat exchanger maintenance and more time focusing on production.

Minimal Downtime

Facilities value equipment that keeps downtime to a minimum. The Gasketed Plate Heat Exchanger from Shanghai Heat Transfer stands out for its user-friendly engineering. Maintenance teams can quickly inspect, clean, or replace plates as needed. This design reduces the time required for routine checks and repairs.

Regular maintenance is easier with plate and frame models compared to shell and tube types. The following table shows the difference in maintenance methods:

Heat Exchanger Type | Maintenance Method |

|---|---|

Plate and Frame | Complete disassembly, high-pressure water cleaning, chemical cleaning, and leak testing. |

Shell and Tube | Cleaning typically involves mechanical devices or chemical cleaning, with the bundle needing to be pulled. |

Shanghai Heat Transfer’s engineering team also provides support and guidance, making it easier for operators to keep their systems running smoothly. This approach helps facilities avoid long shutdowns and maintain high productivity.

Compact Size and Footprint

Space-Saving Design

Facilities often struggle with limited installation space. The plate and frame heat exchanger offers a solution with its compact structure. Stacked plates create a large surface area for heat transfer, yet the unit occupies much less room than traditional shell and tube systems. Many installations report a footprint reduction of up to 70–90% compared to a shell and tube heat exchanger. This advantage allows engineers to maximize available space and fit equipment into tight mechanical rooms or crowded production floors.

Tip: Choosing a plate and frame heat exchanger from Shanghai Heat Transfer helps facilities save valuable floor space while boosting thermal performance.

Flexible Installation

Industrial environments require adaptable solutions. The modular design of plate and frame heat exchangers enables users to add or remove plates as needed. This flexibility supports a wide range of capacity requirements and simplifies upgrades or changes in process demands. Operators can install these units vertically or horizontally, depending on the available space. The adaptability makes them ideal for retrofits, expansions, or new builds where layout constraints exist.

Modular construction allows easy customization.

Units fit into spaces where shell and tube systems cannot.

Shanghai Heat Transfer provides engineering support for tailored installations.

Facilities benefit from a heat exchanger that fits their unique needs and grows with their operations. The compact footprint and flexible installation options make the plate and frame heat exchanger a preferred choice for modern industry.

Expandability and Flexibility

Modular Plate Addition

Plate and frame systems offer unmatched flexibility for growing operations. When a facility needs more heat transfer capacity, technicians can expand the plate and frame heat exchanger by adding plates. This process follows a clear sequence:

Determine the desired increase in performance, such as boosting flow from 10 GPM to 15 GPM.

Calculate the number of plates to add. For a 50% increase, add 50% more plates.

Add plates in pairs to maintain the honeycomb pattern, placing one left and one right plate together.

Ensure an equal number of plates are added to each pass of the heat exchanger.

Calculate the new A measure before reassembling the unit.

This modular approach allows facilities to respond quickly to changing demands without replacing the entire system. Plate and frame systems make upgrades simple and cost-effective.

Adapts to Changing Needs

Shanghai Heat Transfer supports clients with advanced engineering and customization. Their team helps select the right model and configuration for each application. The company offers over 200 models, each designed for specific requirements. The following table highlights key customization features:

Feature | Description |

|---|---|

Full-Scale Customization | Over 200 engineered models available for diverse applications. |

Technical Consultation | Expert guidance for plate selection based on operating conditions. |

Plate Size | |

Unique Corrugation Pattern | Custom patterns enhance performance for client needs. |

Material Selection | Materials chosen to meet operational requirements. |

Shanghai Heat Transfer’s engineering support ensures every plate and frame system matches the client’s needs. Facilities benefit from a solution that grows with their business and adapts to new challenges.

Cost Benefits

Lower Initial Cost

Many facilities look for equipment that delivers strong performance without a high upfront investment. Plate and frame heat exchanger cost is typically lower than shell and tube heat exchanger cost for similar capacities. The following table shows the difference in initial costs:

Parameter | Plate Heat Exchanger | Shell & Tube Heat Exchanger |

|---|---|---|

Cost | Typically lower | Higher upfront cost |

Shanghai Heat Transfer’s Gasketed Plate Heat Exchanger offers a cost-effective solution for businesses that want to maximize their budget. This advantage allows companies to allocate resources to other important areas.

Reduced Operating Expenses

Plate and frame heat exchangers help facilities save money over time. Their robust metal frames last for decades. The main maintenance expense involves replacing rubber gaskets, which usually last five to ten years. This process is simple and affordable. Shell and tube systems often require more complex repairs or replacement, which can increase costs.

Maintenance tasks for plate and frame heat exchangers include:

Cleaning deposits to maintain efficiency.

Inspecting gaskets to prevent leaks.

Checking for pressure drop to identify blockages.

Monitoring heat transfer performance for potential issues.

Energy efficiency also plays a key role in lowering operating expenses. Plate and frame heat exchangers recover more heat and reduce energy waste. Facilities benefit from lower utility bills and improved sustainability. Shanghai Heat Transfer’s engineering team supports clients with guidance to optimize long-term savings.

Tip: Choosing a plate and frame heat exchanger helps businesses achieve reliable performance and cost savings for years.

Pressure Drop and Energy Savings

Lower Pressure Loss

Plate and frame heat exchangers from Shanghai Heat Transfer use an optimized plate design to minimize pressure drop. The corrugated plates create narrow channels that guide fluids efficiently. This design reduces resistance, so fluids move smoothly through the exchanger. In contrast, a shell and tube heat exchanger often has a higher pressure drop because fluids must travel longer paths and navigate around tube bundles. Lower pressure drop means pumps use less energy, which leads to cost savings and less wear on equipment.

Facilities notice that a lower pressure drop helps maintain steady flow rates and reduces the risk of system stress. This benefit is especially important in large-scale operations where energy use adds up quickly.

Improved Energy Efficiency

Plate and frame heat exchangers control fluid temperatures passively, without extra energy input. They recover more heat from industrial processes than a shell and tube heat exchanger. This efficiency leads to significant energy savings and supports sustainability goals. The following table highlights key benefits:

Benefit | Description |

|---|---|

Lower OPEX | Exceptional heat recovery leads to substantial energy savings. |

Performance | A single plate unit can outperform multiple shell and tube systems. |

Environmental Impact | Results in lower energy use, reduced footprint, and fewer CO2 emissions. |

Plate and frame heat exchangers also help reduce greenhouse gas emissions. Their compact design uses less material, which lowers the embodied carbon of each unit. They enable waste heat recovery, so facilities can reuse energy that would otherwise be lost. Shanghai Heat Transfer’s engineering team ensures each unit delivers maximum efficiency with minimal pressure drop.

Plate and frame models enhance thermal efficiency in many industries.

They support renewable energy projects and help companies meet environmental targets.

Shanghai Heat Transfer’s Gasketed Plate Heat Exchanger stands out for its ability to deliver reliable performance, lower pressure drop, and improved energy savings compared to a shell and tube heat exchanger.

Shanghai Heat Transfer’s plate and frame heat exchanger delivers higher efficiency, easy cleaning, and a compact footprint. Facilities save money and gain flexibility. Customers praise the company’s innovation and support. The table below highlights key performance metrics that set this solution apart:

Metric | Plate and Frame | Shell and Tube |

|---|---|---|

Efficiency | Lower | |

Floor Area | Much smaller | Larger |

Cost | 40%-60% lower | Higher |

Contact Shanghai Heat Transfer for expert guidance and a custom solution.

FAQ

What industries use plate and frame heat exchangers?

Plate and frame heat exchangers serve HVAC, chemical processing, power generation, food, and oil and gas industries. Shanghai Heat Transfer’s models adapt to many environments.

How do plate and frame heat exchangers save space?

Stacked plates create a compact unit. Facilities report up to 90% less floor space compared to shell and tube systems. This design fits tight mechanical rooms.

Tip: Shanghai Heat Transfer’s Gasketed Plate Heat Exchanger offers flexible installation for limited spaces.

Can users expand a plate and frame heat exchanger?

Yes. Technicians add or remove plates to adjust capacity. Shanghai Heat Transfer provides engineering support for easy upgrades and custom solutions.