Top Stainless Steel Heat Exchanger Producers of the Year

The best manufacturers of stainless heat exchanger products in 2025 lead with innovation, energy efficiency, and a focus on sustainability. Stainless steel heat exchangers power critical sectors, including power generation, chemical processing, oil and gas, and HVAC systems, where demand keeps rising. Companies push the limits with advanced designs like Printed Circuit Heat Exchangers, helping industries achieve higher thermal performance and smaller footprints. These top producers stand out for their quality, cutting-edge technology, and commitment to meeting evolving industrial needs.

Top 10 Best Stainless Heat Exchanger Manufacturers

SHPHE – Leading Innovation and Quality

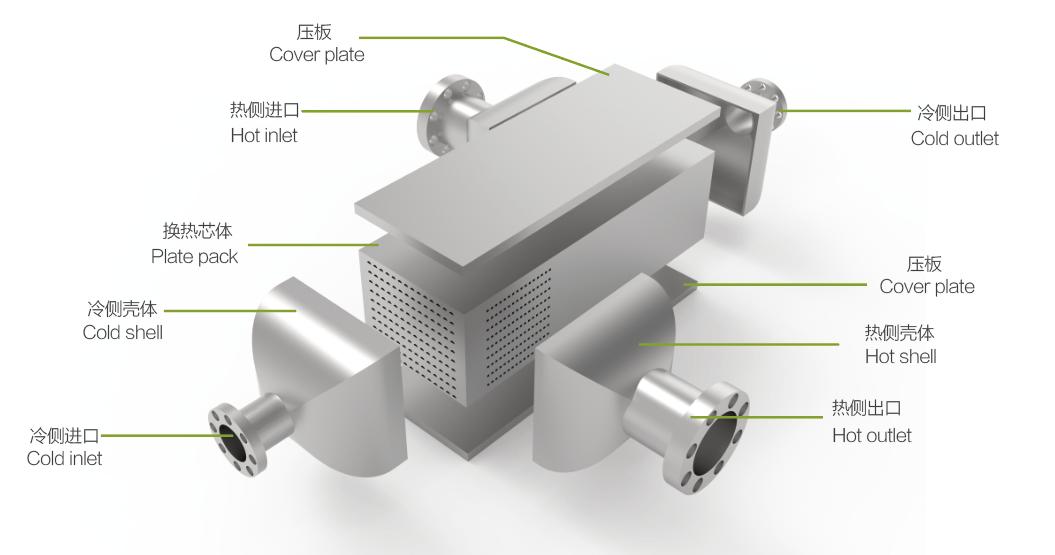

Shanghai Heat Transfer Equipment Co., Ltd. (SHPHE) specializes in the design, manufacturing, installation, and service of plate heat exchangers and complete heat transfer systems. SHPHE uses advanced design and production technologies, along with a deep understanding of heat exchangers and extensive experience in serving customers.

Alfa Laval – Market Leader in Stainless Heat Exchangers

Alfa Laval has earned its place as a global leader in stainless heat exchanger solutions. The company offers a wide range of products, including plate, shell-and-tube, and welded heat exchangers. Alfa Laval’s designs help industries save energy and reduce emissions. Their products are known for high efficiency, robust construction, and easy maintenance. Many customers choose Alfa Laval for their global support network and proven track record.

Kelvion – Advanced Plate and Frame Solutions

Kelvion brings advanced engineering to the world of plate and frame heat exchangers. Their stainless steel models serve industries like power generation, food processing, and chemical manufacturing. Kelvion’s products stand out for their modular design, which allows for easy expansion and customization. The company’s focus on innovation means customers get reliable, high-performance solutions that fit their needs.

Danfoss – Energy-Efficient Technologies

Danfoss leads the way in energy-efficient stainless heat exchanger technology. Their H48T-CH brazed plate heat exchanger uses patented Micro Plate™ technology to optimize heat recovery with water and CO₂. The table below shows what makes Danfoss products unique:

Feature | Description |

|---|---|

Product | H48T-CH brazed plate heat exchanger |

Technology | Patented Micro Plate™ technology |

Application | Optimizes heat recovery with water and CO₂ |

Benefits | Improved heat transfer, enhanced efficiency, reduced environmental impact |

Design | Compact, frame-free for easy installation and space savings |

Danfoss maximizes heat transfer efficiency while keeping energy use low. Their compact designs allow for more surface area, which means better performance with less power. Danfoss also focuses on sustainability. They develop solutions that increase productivity and reduce emissions. Their industrial heat pumps help industries save energy and recover waste heat, making them a top choice for companies that care about the environment.

Hisaka Works – Precision Engineering

Hisaka Works is known for precision engineering and high-quality stainless heat exchangers. The company specializes in plate heat exchangers that deliver consistent performance in demanding applications. Hisaka’s products are popular in the chemical, food, and pharmaceutical industries. Customers appreciate their attention to detail and commitment to quality.

Xylem – Sustainable Water Solutions

Xylem focuses on sustainable water solutions, including advanced stainless heat exchangers. Their products help industries manage water and energy more efficiently. Xylem’s heat exchangers are designed for durability and easy maintenance. The company’s global presence and commitment to sustainability make them a trusted partner for many businesses.

Shanghai Plate Heat Exchanger – PCHE Technology Pioneer

Shanghai Plate Heat Exchanger leads the way in Printed Circuit Heat Exchanger (PCHE) technology. Their PCHEs are engineered for high-demand applications, handling pressures up to 1000 bar and temperatures from -196°C to 850°C. The table below highlights key features:

Feature | Description |

|---|---|

High Pressure & Temperature | Handles up to 1000 bar, -196°C to 850°C |

Compact Design | Up to 85% smaller than traditional exchangers |

Microchannel Efficiency | Channels 0.4–4 mm wide for optimal flow and heat transfer |

All-Welded Construction | Diffusion bonded, leak-free, minimal maintenance |

Versatile Materials | Stainless steel, titanium, and more for compatibility |

Shanghai Plate Heat Exchanger’s PCHEs save up to 80% of the volume compared to shell-and-tube designs. Their compact core and high integrity make them ideal for extreme conditions. Industries like nuclear energy, solar power, and waste heat recovery rely on these exchangers for reliable, efficient performance.

Acerinox – Award-Winning Plate Heat Exchangers

Acerinox is recognized for its award-winning plate heat exchangers. The company uses high-quality stainless steel to ensure durability and corrosion resistance. Acerinox’s products are popular in the food, beverage, and chemical industries. Their focus on innovation and customer satisfaction sets them apart from other manufacturers.

Maharani Industrial Equipments – Shell & Tube Specialist

Maharani Industrial Equipments is a top name in shell and tube heat exchangers. The company is ranked among India’s best manufacturers in this field. They are known for advanced manufacturing processes and customized solutions. Maharani’s products meet international standards like ASME Boiler & Pressure Vessel codes, ensuring safety and durability. Customers trust Maharani for reliable, efficient, and long-lasting equipment.

SPX Flow – Custom Industrial Solutions

SPX Flow delivers custom industrial solutions with a wide range of stainless heat exchangers. Their products serve industries such as food processing, chemical production, and energy. SPX Flow is known for engineering expertise and flexible designs. The company works closely with clients to develop solutions that meet specific process requirements.

Choosing the right stainless heat exchanger manufacturer can make a big difference in performance, efficiency, and long-term value. Each company on this list brings something unique to the table, whether it’s innovation, sustainability, or specialized expertise.

What Sets the Best Manufacturers Apart

Quality and Certifications

Top manufacturers know that quality control is the foundation of every stainless heat exchanger. They use strict quality control systems at every stage, from raw material selection to final inspection. This attention to detail helps them deliver reliable products for demanding industries.

The EN 10204 3.2 certification is crucial for high-spec tubing projects in industries such as oil & gas, power generation, and refineries, as it verifies that the material, testing, and inspection are validated by an independent authority.

Many companies also hold ISO certifications and other international approvals. These certifications show their commitment to rigorous quality control and safety standards.

Technological Innovation

Innovation drives the best manufacturers forward. They invest in research and development to create advanced designs and comprehensive solutions. Their products often feature:

Mechanical strength for tough environments

High thermal conductivity for efficient heat transfer

Hygienic properties for food and pharmaceutical use

Stainless heat exchanger technology keeps evolving. New designs help industries save energy and improve performance. These advances support comprehensive solutions for sectors like energy, manufacturing, and HVAC.

Customer Support and Service

Great manufacturers offer more than just products. They provide end-to-end solutions, including installation, maintenance, and troubleshooting. Their customer support teams respond quickly and help clients solve problems. This level of service builds trust and long-term partnerships. Quality control continues even after delivery, ensuring every unit performs as promised.

Global Reach

The best companies serve customers worldwide. They have production sites, service centers, and technical experts in many countries. This global reach means they can deliver fast support and local expertise. Clients benefit from consistent quality control and access to the latest technology, no matter where they operate.

How to Choose a Stainless Heat Exchanger Manufacturer

Assessing Product Quality

Choosing the right stainless heat exchanger starts with a close look at product quality. Here’s a simple checklist to help anyone make a smart decision:

Understand the requirements. Check the temperature range and pressure rating to see if the heat exchanger fits the job.

Think about fluid allocation. Make sure the design keeps hazardous or toxic fluids safe and reliable.

Look for compatibility. The materials should work well with the fluids to prevent rust and keep the equipment strong.

Review operational conditions. The heat exchanger should fit the space and work well in the environment.

Consider maintenance. Pick equipment that’s easy to maintain and built for long-term use.

Match heat transfer needs. The size and layout should help the system transfer heat efficiently.

Evaluating Reputation

Manufacturers with a strong reputation often deliver better results. People can check reviews, industry awards, and customer testimonials. A company with a history of reliable products and happy customers usually stands out. It helps to ask others in the industry for recommendations. Trust builds over time, and a good reputation shows that a company values quality and service.

Customization and Support

Every project has unique needs. Top manufacturers offer custom solutions and technical support. They listen to clients and adjust designs to fit special requirements. Good support teams answer questions quickly and help solve problems. This kind of service makes the buying process smoother and gives buyers peace of mind.

Warranty and After-Sales Service

A solid warranty shows that a company stands behind its products. After-sales service matters, too. Companies that offer training, spare parts, and fast repairs help keep equipment running longer. Buyers should look for clear warranty terms and strong support after the sale.

Tip: Always ask about warranty details and support options before making a final choice.

Industry Trends for Stainless Heat Exchangers in 2025

Energy Efficiency and Sustainability

Energy efficiency and sustainability shape the future of stainless steel heat exchangers. Companies now design products that save energy and protect the environment. Many focus on new materials and smart coatings to boost performance. The table below shows some of the latest advancements:

Trend/Advancement | Description |

|---|---|

ERD Cross & Counter Flow Tech | Improves heat transfer across wide temperature ranges, saving more energy. |

Hydrophilic/Epoxy Coatings | Reduces fouling and boosts durability, leading to better heat transfer. |

Innovative Materials | Graphene and carbon nanotubes make exchangers lighter and more efficient. |

Focus on Sustainability | Designs now consider the full environmental impact over the product’s life. |

Manufacturers also form partnerships to develop greener solutions. The market keeps growing, with experts predicting it will reach $32.3 billion by 2029. Many companies now look for ways to lower emissions and use resources wisely.

Digitalization and Smart Technology

Digital tools change how industries use heat exchangers. Smart technology helps operators monitor and control equipment in real time. The table below highlights some key digital advancements:

Advancement Type | Description |

|---|---|

Digital Twin Technology | Creates a virtual copy for better monitoring and maintenance. |

IoT Integration | Collects data nonstop for instant performance checks and fault alerts. |

Machine Learning & AI | Learns from past data to improve decisions and predict problems. |

AR & VR Interfaces | Makes training and repairs easier with virtual environments. |

Future Developments | Autonomous operation and quantum computing may soon play a role. |

These tools help companies spot issues early and keep systems running smoothly. Smart heat exchangers now support predictive maintenance, which saves time and money.

Growth in Industrial Applications

Stainless steel heat exchangers now serve more industries than ever. They play a big role in power plants, chemical factories, and renewable energy projects. Many companies want compact, high-performance solutions for tough jobs. The push for smarter, greener systems drives demand for advanced exchangers. Strategic partnerships help companies create products that fit new markets and meet strict standards.

The future looks bright for stainless steel heat exchangers. New technology and a focus on sustainability keep the industry moving forward.

Choosing the right stainless heat exchanger manufacturer gives companies long-term value and peace of mind. The top brands lead with innovation, quality, and a focus on sustainability.

Look for strong certifications and reliable customer support.

Advanced technology makes a big difference in performance.

Staying updated on industry trends helps buyers make smart, future-proof investments.

FAQ

What makes stainless steel heat exchangers a top choice for safety?

Stainless steel heat exchangers offer strong resistance to corrosion. They help maintain safety in harsh environments. Many industries trust these exchangers for reliable performance and food safety standard compliance.

How do manufacturers ensure food safety standard compliance?

Manufacturers follow strict guidelines. They use certified materials and advanced solutions. Regular inspections and testing help meet food safety standard requirements. Customers can ask for documentation to confirm safety.

What services do top manufacturers provide?

Top manufacturers offer installation, maintenance, and repair services. They also provide technical support and training. Customers benefit from a full range of services designed to keep equipment running safely.

Why are advanced solutions important for industrial applications?

Advanced solutions improve efficiency and safety. They help companies meet food safety standard regulations. These solutions also reduce energy use and support sustainability goals.

How do companies guarantee safety in their solutions and services?

Companies use high-quality materials and strict testing. They train staff to follow safety protocols. Their solutions meet food safety standard requirements. Customers receive ongoing support and services to maintain safety.

Tip: Always ask about safety certifications and food safety standard documentation before choosing solutions or services.

😊 Customers value safety and reliable solutions.

🛠️ Services help keep equipment safe and efficient.