Products

TP Welded Plate Heat Exchanger

Certificates: ASME, NB, CE, BV, SGS etc.

In industrial processes, specialized heat exchange solutions are required for handling challenging fluids such as particle-laden fluids (e.g., slurry), viscous fluids (e.g., syrup), and fiber-containing fluids (e.g., pulp). To ensure reliable production operations, targeted heat exchanger design is critical to address challenges such as blockages and leaks caused by those fluids , this requires customized solutions including erosion-resistant materials, optimized channel geometries, and integrated self-cleaning mechanisms. TP Welded Plate Heat Exchanger is an ideal heat exchange solution for these applications.

Key design principles include simplified channel geometries, corrosion- and wear-resistant materials, and integrated CIP (Cleaning-in-Place) systems, combined with preheating to reduce fluid viscosity. These strategies enhance heat transfer efficiency, prevent fouling, and extend equipment lifespan. Such technologies are widely adopted in metallurgy, papermaking, mining, and food processing, providing efficient and reliable solutions for complex industrial fluid handling.

In search of expert advice? Our experienced engineers stand ready to assist you. Discover more about our heat exchangers and compl-ementary services, all designed to precisely align with your needs.

contact us

Product Details

-

What is TP Welded Plate Heat Exchanger?

TP Welded Plate Heat Exchanger is a type of heat exchanger that combines the structural features of a shell and tube heat exchanger and a plate heat exchanger. It is designed to leverage the advantages of both technologies, Combines the compactness and high heat transfer efficiency of plate heat exchangers with the robustness and high-pressure/temperature resistance of shell and tube heat exchangers. This makes it a highly versatile and efficient solution, ideally suited for a wide range of applications, including liquid-liquid, gas-gas, and liquid-gas heat transfer processes. -

How is TP Welded Plate Heat Exchanger Constructed?

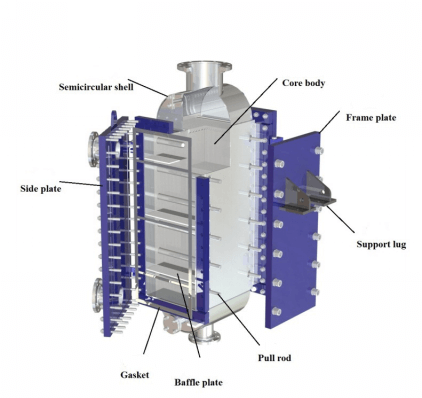

The primary components of the TP Welded Plate Heat Exchanger include one or multiple plate packs, frame of shell and plate, clamping bolts, inlet and outlet connections for both cold and hot sides, baffle plates, and supporting structures. The plate pack is formed by stacking and welding corrugated plates together, with its dimensions varying based on the plate length and the number of plates used.

Depending on the specific process requirements, the tube side shell and plate side shell can be either welded or bolted, ensuring flexibility and adaptability to different operational conditions. This design not only enhances the equipment's durability and performance but also simplifies maintenance and installation processes.

Product Advantage

-

Hybrid Design

Combines the compactness and high heat transfer efficiency of plate heat exchangers with the robustness and high pressure/temperature resistance of shell and tube heat exchangers. -

Openable

Bolted connection is designed to facilitate easy access and versatility by enabling all four sides to be openable. This feature allows for greater flexibility and convenience during cleaning, maintenance, and inspection processes. -

Durabilityy

Withstanding high pressure and extreme temperatures due to corrugated plate and shell frame, it ensures reliable performance in the most challenging operational environments.

Product Parameters

| Parameter Item | Parameter |

|---|---|

| Design Temperature | -196 ~ 900 ℃ |

| Design Pressure | Vacuum ~60 Bar |

| Plate Thickness | 0.6 – 1.5 mm |

| Max. Area | 15000㎡ |

How to design and manufacture

Welded Plate Heat Exchanger

Thermal Design

- Heat Transfer Efficiency: Optimized plate design and spacing to maximize surface area and enhance heat transfer rates.

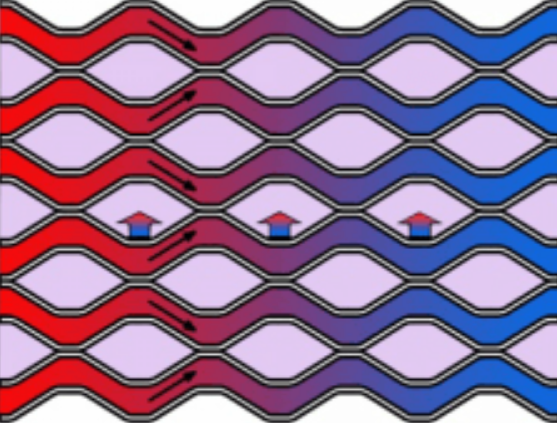

- Flow Arrangement: Multi-passes counter flow or cross flow to improve thermal efficiency based on space and performance needs.

- Pressure Drop Management: Designed to minimize pressure drops, ensuring efficient fluid flow and reducing energy consumption.

Material Selection

- Stainless Steel: Offers excellent corrosion resistance and durability, suitable for a wide range of applications.

- Titanium: Ideal for highly corrosive environments due to chloride, providing superior strength and longevity.

- Hastelloy: Utilized in extremely corrosive conditions, including acidic environments, chloride-rich media, and high temperatures.

Welding and Assembly Techniques

- Precision Welding: Ensures seamless connections between modules, preventing leaks and maintaining structural integrity.

- Precision Welding: Ensures seamless connections between modules, preventing leaks and maintaining structural integrity.

Applications of TP Welded Plate Heat Exchangers

Welded plate heat exchangers, known for their exceptional temperature and pressure resistance, as well as their flexibility, are widely utilized across a variety of industries, including oil and gas, LNG (liquefied natural gas), and chemical processing etc.. Their robust design and adaptability make them an ideal choice for demanding applications in these sectors.

-

Heat Exchange Solutions for Offshore IndustryOffshore modular engineering is a highly technical and comprehensive project, combining specialized design, precision manufacturing, stringent quality control, and full-service after-sales support. These solutions are tailored to meet the unique demands of the marine and ship environments.

Heat Exchange Solutions for Offshore IndustryOffshore modular engineering is a highly technical and comprehensive project, combining specialized design, precision manufacturing, stringent quality control, and full-service after-sales support. These solutions are tailored to meet the unique demands of the marine and ship environments. -

Heat Exchange Solutions for Oil and Gas IndustryOil and Gas industry is a cornerstone of modern industry, with a supply chain covering everything from the extraction and processing of oil and gas to the production and sale of various petrochemical products. These products are widely used in sectors such as energy, chemicals, transportation, construction, and pharmaceuticals, making the industry essential for economic development. Plate heat exchangers are widely applied in the oil and gas industry due to their high efficiency, compact size, corrosion resistance, and ease of maintenance, making them an ideal choice for this sector.

Heat Exchange Solutions for Oil and Gas IndustryOil and Gas industry is a cornerstone of modern industry, with a supply chain covering everything from the extraction and processing of oil and gas to the production and sale of various petrochemical products. These products are widely used in sectors such as energy, chemicals, transportation, construction, and pharmaceuticals, making the industry essential for economic development. Plate heat exchangers are widely applied in the oil and gas industry due to their high efficiency, compact size, corrosion resistance, and ease of maintenance, making them an ideal choice for this sector. -

Heat Exchange Solutions for Chemical IndustryChemical industry is a highly technical sector, combining specialized design, precision manufacturing, and stringent quality control to meet diverse process demands. Plate heat exchangers are essential in this field, providing efficient heat transfer for heating, cooling, condensation, and evaporation. Their compact design, high thermal efficiency, and adaptability to harsh conditions ensure smooth operations, reduce energy consumption, and support sustainability goals.

Heat Exchange Solutions for Chemical IndustryChemical industry is a highly technical sector, combining specialized design, precision manufacturing, and stringent quality control to meet diverse process demands. Plate heat exchangers are essential in this field, providing efficient heat transfer for heating, cooling, condensation, and evaporation. Their compact design, high thermal efficiency, and adaptability to harsh conditions ensure smooth operations, reduce energy consumption, and support sustainability goals.

Related articles

Read More

To Provide You with Better Service

Honor Our Common Journey,Develop Authentic Alliances,Create Collective Success.

Leave Your Message

* Full Name

* Country/Region

* Email

* Company name

* Telephone Number

* Enter your needs

SHPHE has complete quality assurance system from design, manufacturing, inspection and delivery. It is certified with ISO9001, ISO14001, OHSAS18001 and hold ASME U Certificate.