Leakage free air preheater picks that stop waste now

Leakage free air preheater solutions from top bran...

More

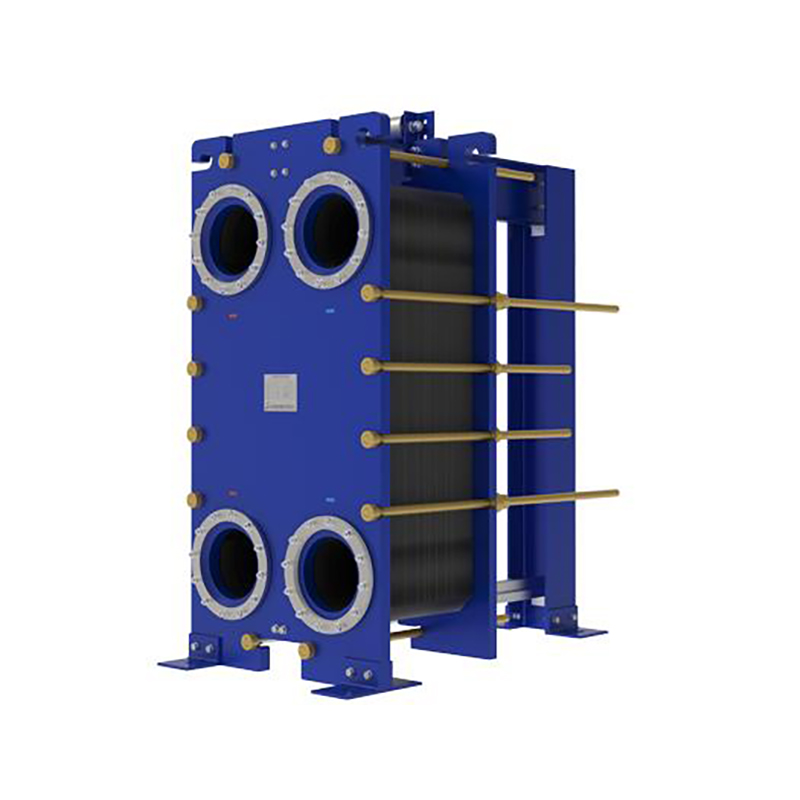

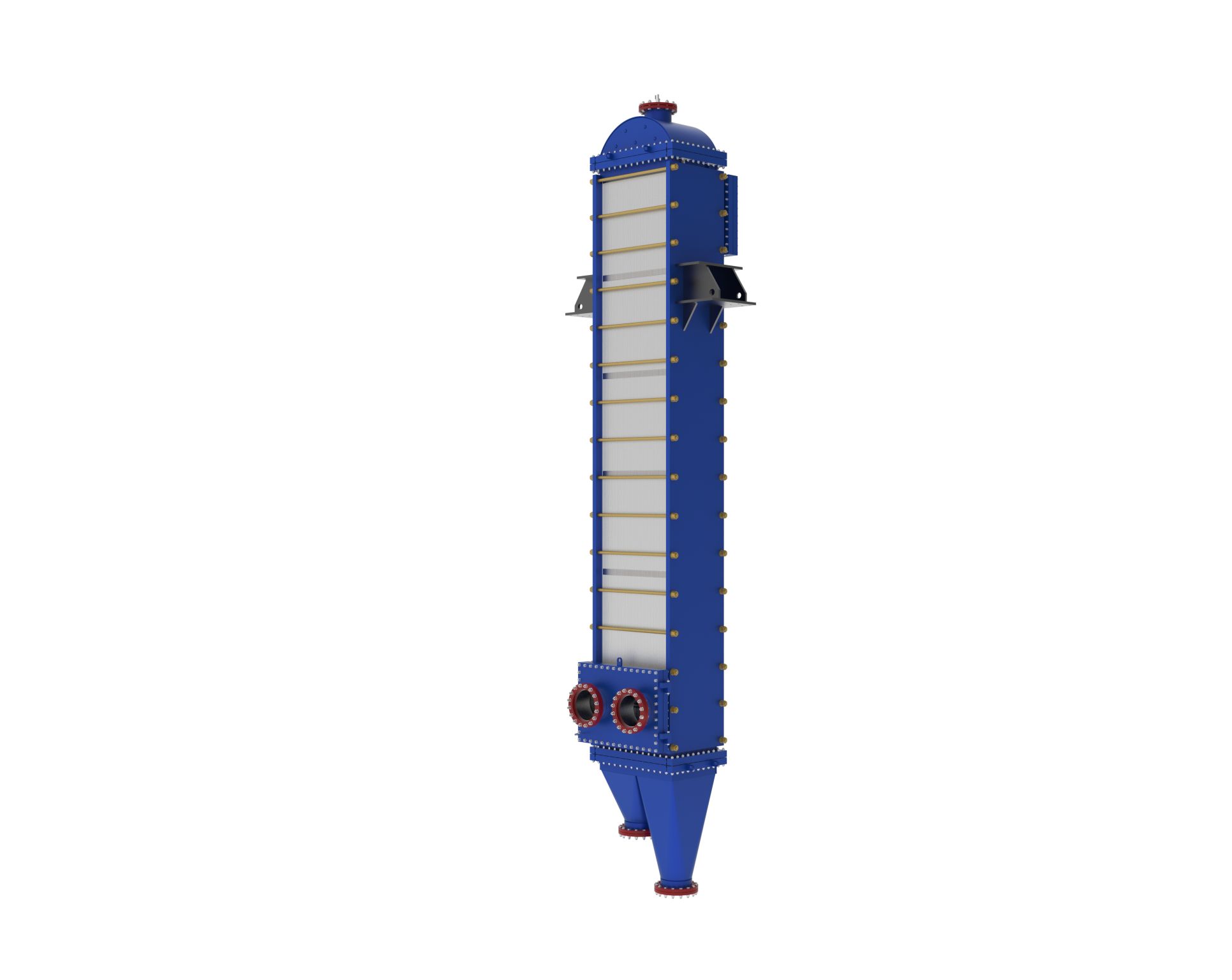

Air preheaters are critical components in boiler systems, enhancing thermal efficiency by recovering waste heat from flue gases to preheat combustion air. There are primarily three types of air preheaters used in boilers: recuperative, regenerative, and heat pipe air preheaters. Recuperative air preheaters, the most common type, use a shell-and-tube design to transfer heat indirectly. Regenerative air preheaters, such as Ljungström or Rothemuhle designs, rotate to alternately absorb and release heat. Heat pipe air preheaters leverage phase change principles for high thermal efficiency.

According to industry data, recuperative air preheaters dominate the market, accounting for over 60% of installations due to their simplicity and reliability. Regenerative types, while more efficient, are costlier and require more maintenance. Heat pipe air preheaters are gaining traction in compact and high-efficiency applications, with a projected CAGR of 5.8% from 2023 to 2030. Leading manufacturers like Howden, Alstom, and Babcock & Wilcox offer customized solutions to reduce boiler fuel consumption by 5-10%. Proper selection depends on factors like boiler size, fuel type, and operational requirements. Investing in the right air preheater can significantly cut emissions and operational costs, making it a key focus for industrial energy optimization.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Leakage free air preheater solutions from top bran...

More

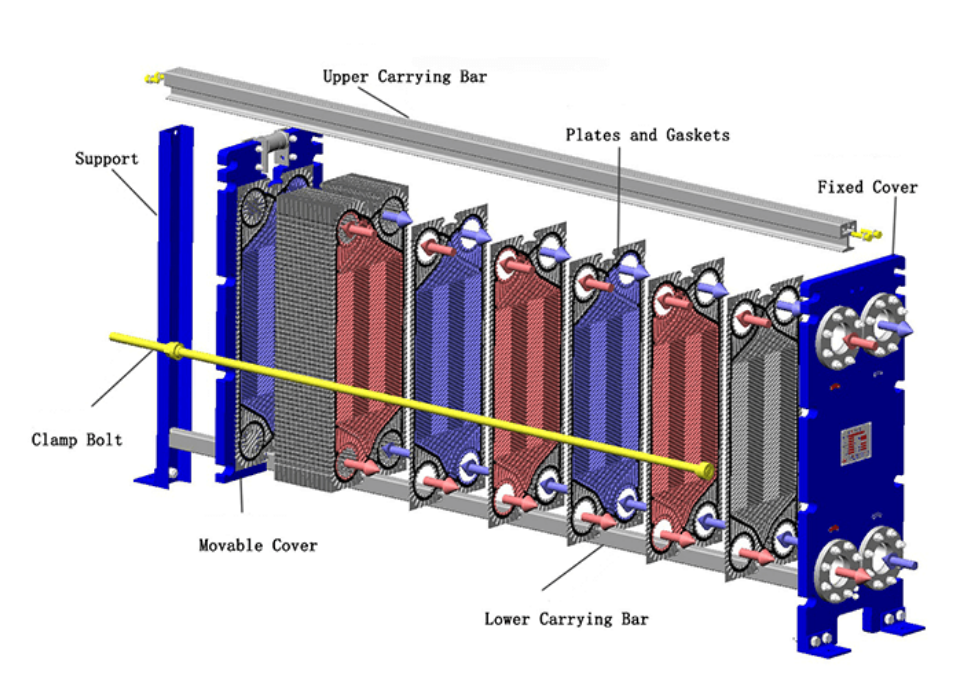

Plate heat exchangers are becoming more popular be...

More

Their adaptability and efficiency make PHEs a go-t...

More

Commercial heat exchangers boost energy efficiency...

More

Plate heat exchanger gaskets in 2025 ensure leak p...

More

A plate heat exchanger (PHE) is a device engineere...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe regenerative air preheater in our boiler has significantly improved efficiency. Highly recommended for power plants!

Emily Johnson

Process EngineerThe tubular air preheater works flawlessly in our chemical plant boiler system. Great heat recovery performance.

Robert Chen

Plant ManagerInstalled a rotary air preheater last month—reduced fuel consumption by 12% in our industrial boiler. Excellent investment!

Sarah Williams

Energy ConsultantThe plate-type air preheater is compact and efficient for small-scale boilers. Perfect for food processing plants.