Understanding api 662 for plate heat exchangers

API 662 stands as a critical guideline for plate heat exchangers in the oil and gas industry. This api standard helps companies like Shanghai Heat Transfer Equipment Co., Ltd. select the right pressure vessel and improve safety. Chemical plants also rely on API 662 to ensure reliable operations.

API 662 Overview

Scope

API 662 sets the standard for plate heat exchangers used in petroleum, petrochemical, and natural gas industries. The scope of this specification includes several important areas that ensure safe and reliable operation. API 662 applies to different types of plate heat exchangers, such as gasketed, semi-welded, and welded models. These exchangers serve in refinery services and perform functions like cooling, heating, condensing, evaporating, and reboiling.

API 662 covers a wide range of objectives and scope areas. The table below summarizes the main points:

Objective/Scope | Description |

|---|---|

Mechanical Design | Covers the minimum requirements for the mechanical design of plate heat exchangers. |

Materials Selection | Specifies the materials to be used in the construction of plate heat exchangers. |

Fabrication | Outlines the fabrication processes for these heat exchangers. |

Inspection | Details the inspection requirements to ensure quality and safety. |

Testing | Includes testing protocols to validate performance. |

Preparation for Shipment | Describes the procedures for preparing heat exchangers for shipment. |

General Use | Applicable for plate heat exchangers in refinery services. |

Types of Heat Exchangers | Covers gasketed, semi-welded, and welded plate heat exchangers. |

Applications | Includes coolers, heaters, condensers, evaporators, and reboilers. |

API 662 also aligns with ISO 15547, which provides similar requirements for brazed aluminum plate-fin heat exchangers and plate-and-frame heat exchangers. Both standards focus on mechanical design, materials selection, fabrication, inspection, testing, and shipment preparation. This alignment helps ensure global consistency in safety and performance.

Requirements

API 662 outlines strict requirements for plate heat exchanger specification and operation. The standard mandates the use of high-quality materials and precise fabrication methods. Inspection and testing protocols help verify that each exchanger meets safety and performance expectations.

API 662 sets limits for design pressures and temperatures. For example, the standard does not recommend plate heat exchangers for design pressures above 30 bar abs (435 psia) or design temperatures above 260°C (500°F). These limits help maintain safety and reliability in industrial applications.

Key safety standards in API 662 include:

Reference to BP GS 126-5 and ISO 15547-1 for plate heat exchanger design.

Surface margin described as a relative value.

Plate heat exchangers are not recommended for high-pressure or high-temperature applications.

Operational requirements in API 662 focus on nozzle loads and expansion joints. The allowable nozzle loads for plate and frame exchangers remain extremely low. For moderate operating temperatures, two expansion joints per nozzle in different axes are required. Table 2 in the standard provides guidance for severe service, especially for offshore applications.

API 662 ensures that every plate heat exchanger meets strict specification criteria. The standard covers all aspects from design to shipment, helping companies achieve safe, efficient, and reliable heat transfer solutions.

Plate Heat Exchanger Types

Plate heat exchangers come in several main types, each designed for specific industrial needs. Shanghai Heat Transfer Equipment Co., Ltd. (SHPHE) manufactures a wide range of these exchangers, offering solutions for oil and gas, chemical, and other industries.

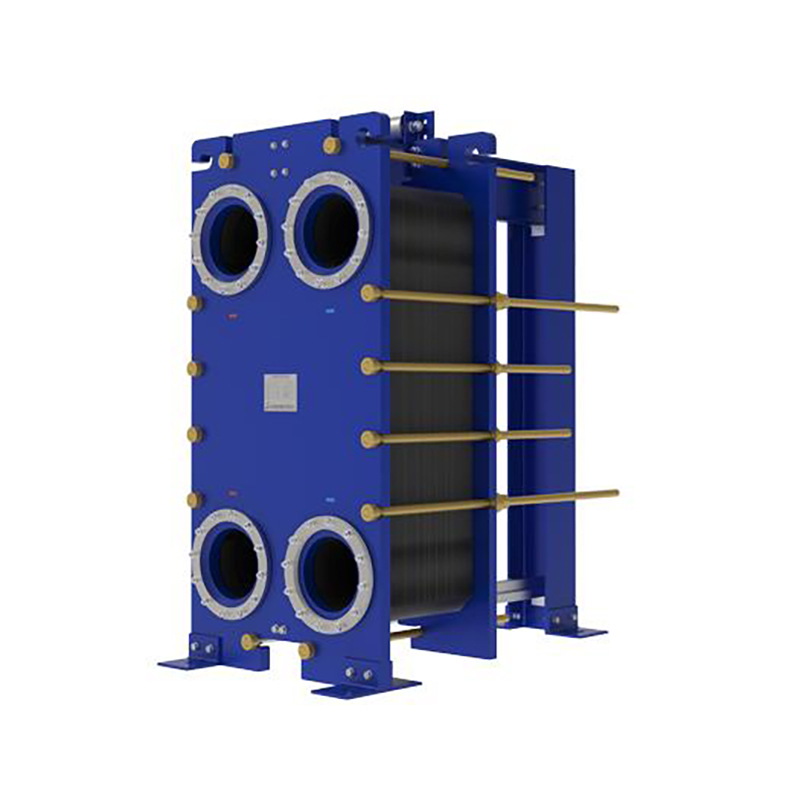

Gasketed

Gasketed plate heat exchangers use elastomeric gaskets to seal the plates. This design allows for easy disassembly and cleaning. Operators can add or remove plates to adjust capacity. These exchangers work well in applications that require frequent maintenance or cleaning, such as fluid preheating, vapor cooling, and oil product heating. Gasketed models are ideal for processes where adaptability and regular servicing are important.

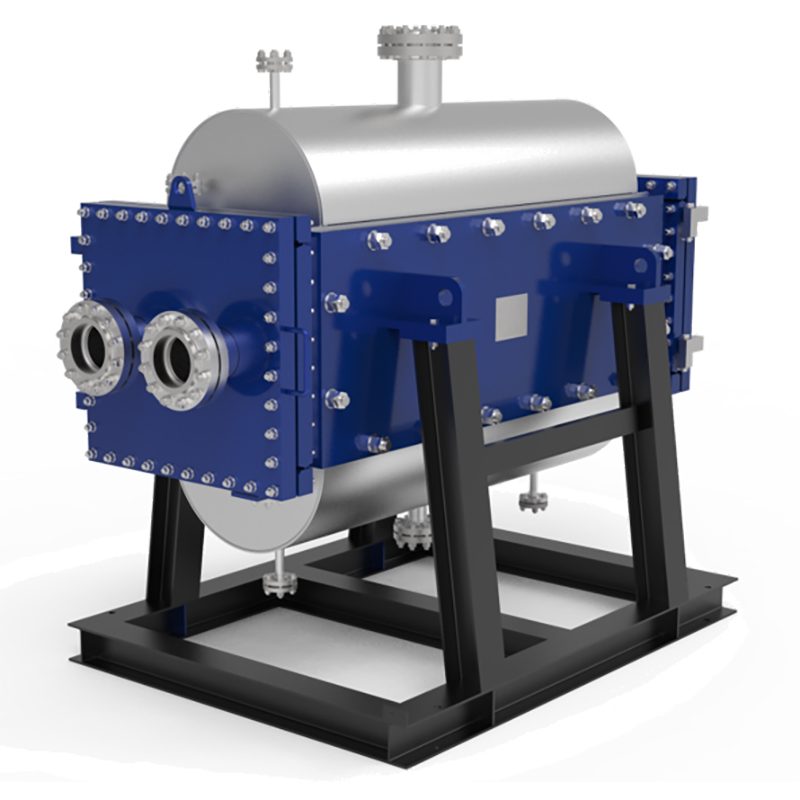

Welded

Welded plate heat exchangers feature plates that are permanently joined by welding. This construction removes the need for gaskets, reducing maintenance and the risk of leaks. Welded exchangers handle higher pressures and temperatures, making them suitable for harsh environments and corrosive fluids. However, they cannot be easily disassembled for cleaning or repair.

Advantages | Limitations |

|---|---|

Withstand extreme temperatures and corrosive fluids | Higher initial costs |

Minimal maintenance due to no gaskets | Less flexible for maintenance and modifications |

Compact design | Cannot be easily disassembled for cleaning |

High thermal efficiency |

Brazed Aluminum Heat Exchangers

Brazed aluminum heat exchangers use plates bonded together by brazing, creating a compact and leak-resistant unit. These exchangers offer high thermal efficiency and a small footprint, about 75% smaller than traditional shell-and-tube designs. The lightweight construction and tailored plate design allow for efficient heat transfer in various applications. SHPHE’s expertise ensures reliable quality and long service life for these exchangers.

Feature | Description |

|---|---|

Highly Efficient Thermal Design | Enhances heat transfer between fluids |

Proven and Reliable Quality | Ensures long lifetime durability |

Compact Size | 75% smaller than traditional shell-and-tube exchangers |

Lightweight Construction | Reduces overall system size |

Flexible Distribution System | Adapts to different refrigerants and applications |

Thermal Performance

Efficiency

Thermal efficiency measures how well a plate heat exchanger transfers heat between fluids. API 662 specifies that plate heat exchangers in oil and gas applications typically achieve an efficiency range of 80–95%. This high thermal efficiency results from the unique plate design, which creates turbulence and a uniform velocity profile. The following table highlights key factors affecting thermal efficiency:

Key Factor | Description |

|---|---|

Fouling Factor | Plate heat exchangers require a fouling factor only 1/10 that of shell & tube heat exchangers. |

Impact of Deposits | Deposits form insulating layers, decreasing heat transfer and increasing pressure drop. |

Turbulence and Velocity | Higher turbulence and uniform velocity reduce fouling and improve thermal performance. |

Different plate configurations also influence thermal performance. Non-parallel plates and modified flat plate designs show higher Nusselt numbers and lower friction factors, leading to better temperature uniformity and reduced risk of thermal shock. Brazed plate heat exchangers often outperform conventional designs in terms of thermal efficiency.

Shanghai Heat Transfer Equipment Co., Ltd. enhances operation with the 'Smart Eye' monitoring system. This digital solution monitors temperature and pressure drop in real time, providing early warnings and optimizing energy use. The system helps prevent accumulated thermal fatigue and thermal fatigue cracking by maintaining ideal operating conditions.

Fouling Margin

Fouling margin refers to the allowance made for the buildup of deposits on heat exchanger surfaces. API 662 recommends a minimum fouling margin of 10% for plate heat exchangers. Cooling water often carries suspended particles that adhere to plates, causing fouling and scaling. Over time, these insulating layers reduce thermal performance and may lead to thermal fatigue damage or even full blockage of channels.

Plate heat exchangers from SHPHE minimize fouling through enhanced turbulence and robust plate geometry. The design resists thermal shock and accumulated thermal fatigue, ensuring reliable operation and extending service life. The 'Smart Eye' system further supports continuous monitoring, allowing quick response to any performance degradation.

Industry professionals recognize what API 662 provides for plate heat exchanger selection and operation. SHPHE’s reliability comes from strict quality control at every stage, reducing fatigue and failure caused by temperature fluctuations. The table below shows what resources help professionals stay updated on standards.

Resource Type | Description |

|---|---|

API Standards Subscription | Access standards, analyze available standards, and receive alerts for new standards through a direct licensing platform. |

API Learning | Offers comprehensive training on API Standards and Recommended Practices through multi-platform eLearning. |

Standards Plan | Lists standards in development by industry segment, including those in pre-ballot, ballot, and editing stages. |

What decision-makers face includes selecting materials with high mechanical strength and corrosion resistance. Many refineries retrofit to plate-and-shell designs for higher efficiency and lower energy demands. SHPHE offers customization to meet specific process requirements. Consulting API 662 ensures proper design and operation.

FAQ

What is API 662 and why does it matter for plate heat exchanger selection?

API 662 is a guideline that sets the specification for plate heat exchanger design and operation. It helps companies choose safe, efficient exchangers for oil and gas applications.

What types of exchangers does API 662 cover?

API 662 covers gasketed, welded, and brazed aluminum heat exchangers. Each type meets different needs for pressure, temperature, and operation in industrial processes.

What causes thermal fatigue cracking or failure in plate heat exchangers?

Thermal fatigue cracking or failure often results from temperature fluctuations, thermal shock, or accumulated thermal fatigue during operation. Proper design and monitoring help prevent damage.