Frame Plate

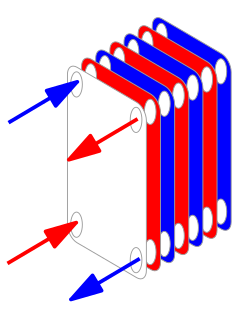

Quick definition:

The frame plate is the fixed end cover of a plate-and-frame heat exchanger. It anchors the carrying/guide bars, supports the plate pack, carries the main nozzles and data nameplate, and serves as the datum for alignment and the specified A-dimension (tightening length).

Where the Frame Plate Sits

Piping / Nozzles │ [ FRAME PLATE ] ← fixed head with ports + data tag ┌───────────────┐ │ ◉ ◉ │ ← corner/port openings │ │ └───────────────┘ ║ Plate pack (corrugated plates + gaskets) ║ … … … … [ PRESSURE PLATE ] ← movable follower (closes the pack) ↑ ↑ Tie bolts along rails (carrying bar + guide bar)

Core Functions

1) Primary support

Anchors the carrying bar (upper rail) and guide bar (lower rail) to align plates and the pressure plate.

2) Pressure boundary

Forms one side of the pressure envelope and interfaces with nozzles/ports.

3) Compression datum

Defines the reference for closing to the specified A-dimension (tightening length).

4) Load transfer

Transmits tie-bolt loads and external piping loads into the frame structure.

5) Marking & traceability

Hosts the nameplate (model, serial, design pressure/temperature, test pressure, materials, certifications).

Construction & Key Features

| Feature | What to look for | Why it matters |

|---|---|---|

| Base material | Painted carbon steel (cost-effective) or stainless steel for corrosive/clean areas | Balance structural strength, corrosion resistance and hygiene |

| Surface finish | Industrial coatings (CS) or bead-blasted/polished (SS) | Durability, cleanability and appearance |

| Nozzles/ports | Flanged, Tri-Clamp, DIN unions, threaded, or butt-weld stubs | Compatibility with plant standards and sanitary needs |

| Sealing land | Flat, damage-free area contacting the end-plate gasket | Uniform gasket compression & leak-tight sealing |

| Rails & column | Machined/bolted interfaces for carrying/guide bars + plumb support column | Straight tracking for plates and pressure plate |

| Lifting/feet | Lifting eyes/lugs, adjustable feet or base pads | Safe handling, easy leveling |

| Nameplate pad | Protected flat area for data tag | Legible compliance markings |

Materials & Coatings

· Carbon steel + epoxy/polyurethane coating for industrial cooling/heating water.

· Stainless steel 304/316 for hygienic areas, frequent wash-downs, or coastal plants.

· Upgraded systems where chemical splash or UV exposure requires enhanced protection.

Ports & Connections

Match your plant standard and duty. Common options include:

· Flanges to ASME B16.5 (NPS) or EN 1092-1 (DN)

· Tri-Clamp / Tri-Clover (ISO 2852) for sanitary lines

· DIN 11851 dairy unions, SMS unions, or grooved mechanical couplings

· Butt-weld stubs for direct weld-in piping

Tolerances, Flatness & Compression

The frame-plate sealing surface must meet OEM flatness tolerance to ensure uniform gasket loading. Closing to the specified A-dimension achieves the designed gasket compression—too short risks plate deformation; too long risks leakage.

Loads & Structural Considerations

| Load type | Source | Design consideration |

|---|---|---|

| Internal pressure | Process conditions | Frame stiffness and plate contact support |

| Piping loads | Misalignment, dead weight, thermal growth | Nozzle reinforcement, external pipe supports |

| Bolt tension | Closing torque & operating cycles | Tie-bolt size/material, lubrication, even tightening |

| Thermal movement | Heat-up / cool-down | Allowable frame deflection without misalignment |

| Transport/installation | Lifting, vibration | Lugs rated for mass; anchoring and skid support |

Common Variants

· Sanitary frame plate: smooth surfaces, drainable geometry, sanitary ferrules, minimal crevices.

· High-pressure frame plate: thicker section, reinforced nozzles, upgraded tie-bolts.

· Corrosion-resistant: stainless frame or enhanced coatings for harsh environments.

· Steam-service friendly: expansion allowances and compatible gasket selection.

Frame Plate vs. Pressure Plate

| Item | Frame Plate (Fixed) | Pressure Plate (Movable/Follower) |

|---|---|---|

| Mobility | Fixed to support column & rails | Slides for opening/closing |

| Main role | Datum, nozzles, nameplate | Applies compression to plate pack |

| Service removal | Typically remains installed | Withdrawn for plate service |

| Alignment sensitivity | Sets pack alignment with bars | Must remain square while tightening |

Installation & Maintenance Essentials

During installation

· Level the base; check plumb of support column.

· Verify nozzle orientation vs. P&ID; keep headroom to pull plates.

· Torque tie-bolts in a cross pattern with lubrication to reach the A-dimension.

During operation

· Monitor for seepage at the end-plate region; re-check A-dimension after initial thermal cycles.

· Limit piping loads with proper supports and flexible connectors if needed.

During service

· Inspect sealing land for dents/paint; dress only per OEM guidance.

· Check coating integrity (CS frames) and repair per coating system.

· Verify nameplate legibility; keep docs aligned with serial numbers.

Inspection Checklist

| Checkpoint | Accept / Action | Notes |

|---|---|---|

| Frame flatness at sealing area | Within OEM tolerance | Feeler gauge or straightedge |

| Rail alignment | Plates slide smoothly; no binding | Confirm plate A/B alternation |

| Nozzle integrity | No paint on faces; correct gasket | Check per plant standard |

| Tie-bolt condition | Threads clean; nuts lubricated | Replace damaged studs/nuts |

| Coating/finish | No rust, blisters, chips | Touch up if needed |

| Nameplate | Legible, complete data | Model/serial/MAWP/MDMT |

| A-dimension | Matches datasheet after close | Re-measure after heat-up |

Troubleshooting

| Symptom | Likely cause (frame-related) | Remedy |

|---|---|---|

| Persistent corner seepage | Sealing land damage or uneven compression | Dress surface per OEM, re-close to A-dimension, check gasket |

| Difficult plate movement | Rail misalignment or burrs | Clean/deburr rails, verify column plumb |

| Nozzle leaks at flange | Paint on face / wrong gasket / piping strain | Clean face, correct gasket, add pipe supports |

| Uneven A-dimension | Non-cross tightening or bolt galling | Back off, re-lubricate, cross-pattern torque |

RFQ/Datasheet Fields

| Field | Example |

|---|---|

| Service & fluids | District cooling water ↔ process water |

| MAWP / Design temperature | 16 bar(g) / 180 °C |

| Materials | Frame: CS + epoxy; Ports: SS316; Plates: SS316L |

| Connections | DN100 PN16 flanges (or 4" 150#) |

| Hygienic? | Yes (Tri-Clamp, surface finish target Ra ≤ 0.8 µm) |

| Coating system | Epoxy primer + PU topcoat, color RAL **** |

| Nameplate | Language, units (SI/I-P), compliance marks |

| Site conditions | Ambient, corrosion category, wash-down? |

FAQs

Q1: Is the frame plate always the side with ports?

Usually yes, but some OEMs place certain nozzles on the follower for layout reasons. Always confirm GA drawings.

Q2: Can I machine the sealing land if it’s scratched?

Only per OEM guidance and within flatness allowance; aggressive machining can compromise gasket compression.

Q3: Does the frame plate determine left/right service orientation?

Yes—its port layout sets the piping orientation and pass arrangement. Confirm against PFD/P&ID before fabrication.

Q4: What’s the most common damage you see?

Paint or dent on the sealing land, and piping strain at nozzles. Both lead to leaks and misalignment.