Unlocking Energy Savings in Industrial Applications with Plate Heat Exchangers

How Plate Heat Exchangers Deliver Energy Savings

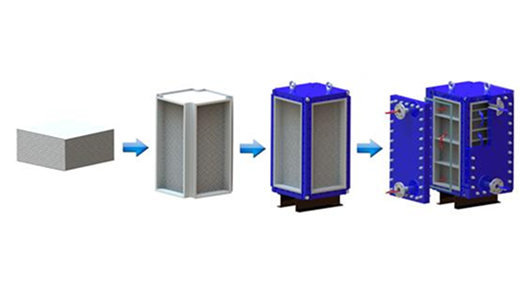

Efficient Heat Transfer Design

Engineers design plate heat exchangers to maximize surface area for heat transfer. Each unit contains multiple thin, corrugated plates stacked together. These plates create turbulent flow, which increases the rate of heat exchange between fluids. The design allows for rapid temperature changes, which helps industries recover more energy from process streams. Many facilities choose this technology because it delivers higher thermal efficiency compared to traditional shell-and-tube exchangers.

A plate heat exchanger can achieve up to 90% heat recovery in some industrial processes. This high efficiency leads to significant reductions in fuel consumption and energy costs.

Compact Size and Flexibility

A plate heat exchanger offers a compact footprint, making it ideal for facilities with limited space. The modular design allows operators to add or remove plates to match changing process requirements. This flexibility supports a wide range of applications, from small-scale operations to large industrial plants.

·Space-saving installation

·Easy maintenance and cleaning

·Adaptable to different flow rates and temperatures

Facilities benefit from the ability to upgrade or modify their systems without major equipment changes. This adaptability reduces downtime and supports continuous improvement in energy management.

Reduced Energy Losses

Plate heat exchangers minimize energy losses through efficient insulation and precise temperature control. The close spacing of the plates reduces heat loss to the environment. Operators can maintain tighter temperature approaches, which means less wasted energy during heat transfer.

| Feature | Benefit |

|---|---|

| Tight plate spacing | Lower heat loss |

| High turbulence | Improved energy recovery |

| Modular construction | Optimized performance |

By reducing energy losses, industries lower their overall energy consumption. This approach supports both cost savings and environmental goals.

Plate Heat Exchanger Applications and Industrial Benefits

Power Generation

Power plants rely on plate heat exchangers to improve thermal efficiency. These units transfer heat between steam and cooling water. Operators see lower fuel consumption and reduced emissions. The compact design fits easily into existing systems.

Chemical Processing

Chemical manufacturers use plate heat exchangers to control reaction temperatures. The equipment handles corrosive fluids and high pressures. Engineers select these exchangers for their reliability and easy maintenance. Production lines operate with greater safety and energy savings.

Heating and Cooling Systems

Industrial facilities install plate heat exchangers in heating and cooling loops. The technology supports precise temperature control. Maintenance teams appreciate the quick cleaning process. Energy managers report lower utility bills and improved system performance.

Food and Beverage Manufacturing

Food processors depend on plate heat exchangers for pasteurization and sterilization. The design prevents contamination and supports hygienic operations. Production managers achieve consistent product quality and faster processing times.

Pharmaceutical Production

Pharmaceutical plants require strict temperature regulation. Plate heat exchangers deliver accurate heat transfer for sensitive ingredients. The equipment meets industry standards for cleanliness and safety. Operators maintain product integrity and reduce energy costs.

HVAC and Building Services

Commercial buildings use plate heat exchangers in HVAC systems. The units recover waste heat and support efficient climate control. Facility managers benefit from lower operating expenses and enhanced comfort for occupants.Industries recognize plate heat exchangers as vital tools for reducing energy consumption and operational costs. Their adaptable design supports sustainable practices. Facilities that implement this technology achieve long-term savings and demonstrate environmental responsibility.

·Efficiency drives lower expenses.

·Adaptability supports future growth.

FAQ

What maintenance does a plate heat exchanger require?

Operators clean plates regularly and inspect for leaks. They replace gaskets as needed. Proper maintenance ensures efficient heat transfer and extends equipment lifespan.

How does a plate heat exchanger improve energy efficiency?

The design maximizes heat transfer between fluids. Facilities recover more energy from process streams. This approach reduces fuel consumption and lowers operational costs.

Can plate heat exchangers handle high-pressure applications?

Engineers select models with reinforced plates and robust frames. These units operate safely under high pressure. Industries rely on them for demanding environments.