Plate Heat Exchanger Applications in Food Processing

Plate heat exchangers deliver high thermal efficie...

More

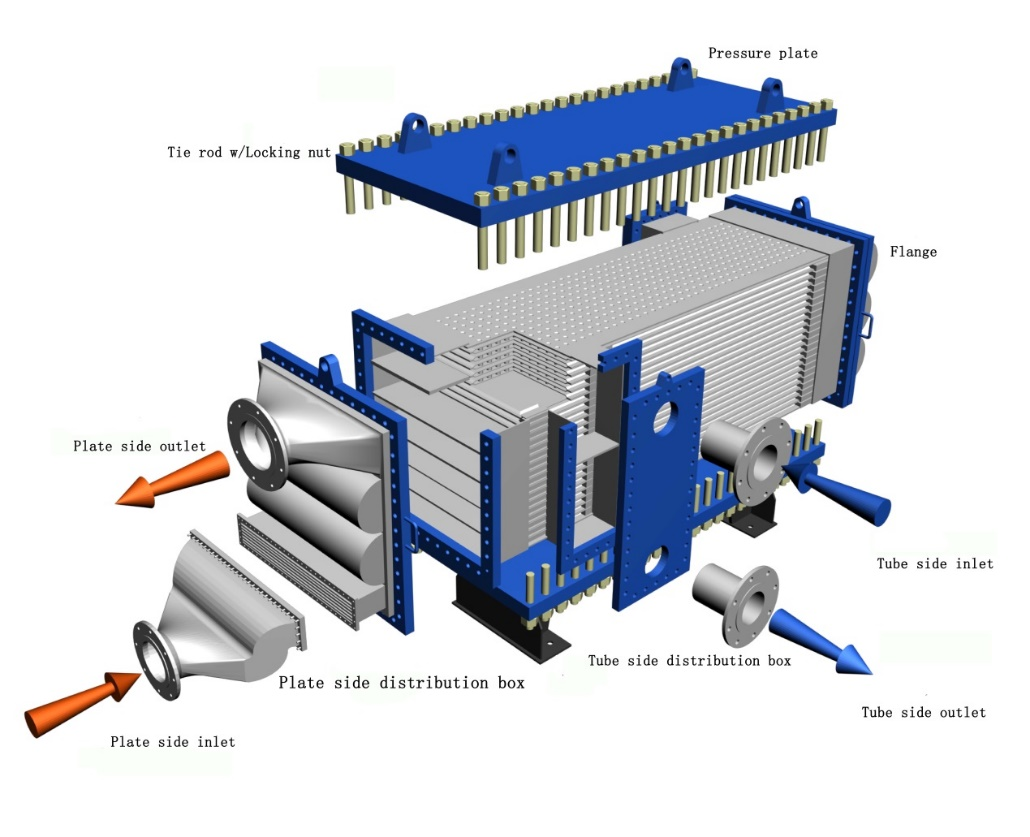

Welded block heat exchangers are essential components in industrial and HVAC systems, but they can develop issues over time due to thermal stress, corrosion, or fouling. Common problems include leaks, reduced efficiency, and blockages. To fix a welded block heat exchanger, start by identifying the root cause—whether it’s a cracked weld, scaling, or gasket failure. For minor leaks, welding repairs or epoxy sealing can be effective, while severe damage may require replacing the entire block. Regular maintenance, such as chemical cleaning to remove deposits, can prevent costly downtime. According to industry reports, proper maintenance can extend the lifespan of a welded block heat exchanger by up to 30%, saving thousands in replacement costs.

For optimal performance, consider upgrading to a high-efficiency welded block heat exchanger with advanced materials like stainless steel or titanium, which resist corrosion and withstand higher pressures. Data from market research shows that modern designs improve thermal efficiency by 15-20% compared to traditional models. If troubleshooting fails, consult a certified technician for professional assessment. Many manufacturers offer on-site repair services, with some providing warranties on welded repairs. Investing in predictive maintenance tools, such as thermal imaging or vibration analysis, can also help detect early signs of failure. Studies indicate that predictive maintenance reduces unplanned outages by 50%, making it a cost-effective solution for industrial operations. Always follow OEM guidelines to ensure safety and compliance during repairs.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchangers deliver high thermal efficie...

More

Understanding welded heat exchanger's unique const...

More

Recently, SHPHE received repeat order from custome...

More

Printed circuit heat exchangers (PCHEs) are a cutt...

More

Blocked PHEs can significantly reduce performance,...

More

Heat exchangers transfer heat between fluids witho...

MoreExplore more content related to foreign trade services