Welded PHE for High Pressure Picks Powering Progress

Shanghai Plate Heat Exchanger, Alfa Laval, Kelvion, and Tranter lead the field in welded PHEs for high-pressure applications. The HT-Bloc from Shanghai Plate Heat Exchanger delivers advanced performance through robust construction and innovative modular design. These manufacturers excel by offering reliable solutions for demanding sectors such as chemical processing, power generation, and oil and gas. Selecting the right welded PHE for high pressure ensures safe, efficient operation and long-term value.

The global welded plate heat exchanger market reached USD 1.74 billion in 2024 and is projected to grow at 6.1% CAGR.

Growth is driven by investments in energy efficiency and expansion of process industries.

Welded PHE for High Pressure Overview

What Is a Welded PHE?

A welded plate heat exchanger (PHE) is a compact device designed to transfer heat between two fluids. Its structure consists of thin metal plates welded together, forming a series of channels for fluid flow. This construction provides excellent sealing and high resistance to pressure. The plates feature a corrugated pattern, which increases turbulence and improves heat transfer efficiency. Welded PHEs operate on either counterflow or crossflow principles. Hot and cold fluids move through adjacent channels, allowing for maximum thermal exchange. The absence of gaskets means fewer maintenance requirements and a longer service life.

Component | Description |

|---|---|

Plates | Welded together for superior sealing and pressure resistance |

Design | Corrugated plates create turbulence and boost heat transfer |

Operation | Counterflow or crossflow maximizes thermal efficiency |

Why Choose Welded PHEs for High Pressure?

Welded PHE for high pressure offers several advantages over other types. These units withstand extreme temperatures and resist thermal shock, making them ideal for demanding environments. Their countercurrent flow design enhances heat transfer efficiency. The lack of gaskets eliminates common failure points and reduces maintenance needs. Welded PHEs also feature a compact footprint, saving valuable floor space in industrial plants.

Durability: Handles high pressure and temperature without damage.

Efficiency: Delivers superior heat transfer through advanced flow patterns.

Minimal Maintenance: No gaskets to replace, leading to lower upkeep costs.

Space Saving: Compact design supports plant expansion and modernization.

Key Industrial Applications

Many industries rely on welded PHE for high pressure to ensure safe and efficient operations. These exchangers play a vital role in sectors where reliability and performance are critical.

Industry | Typical Applications | Operating Conditions |

|---|---|---|

Aggressive chemicals, high pressures, extreme heat | High pressure, extreme temperatures | |

Oil & Gas | Gas processing, refinery operations | High pressures, corrosive fluids |

Power Generation | Waste heat recovery, condenser cooling | Often high pressure |

Food & Beverage | Pasteurization, sterilization, hygienic processes | Precise control, varied conditions |

HVAC | District heating/cooling, heat recovery | Compact, energy-efficient |

Note: Welded PHE for high pressure ensures reliable performance in environments where safety, efficiency, and durability are essential.

Top Manufacturers of Welded PHE for High Pressure

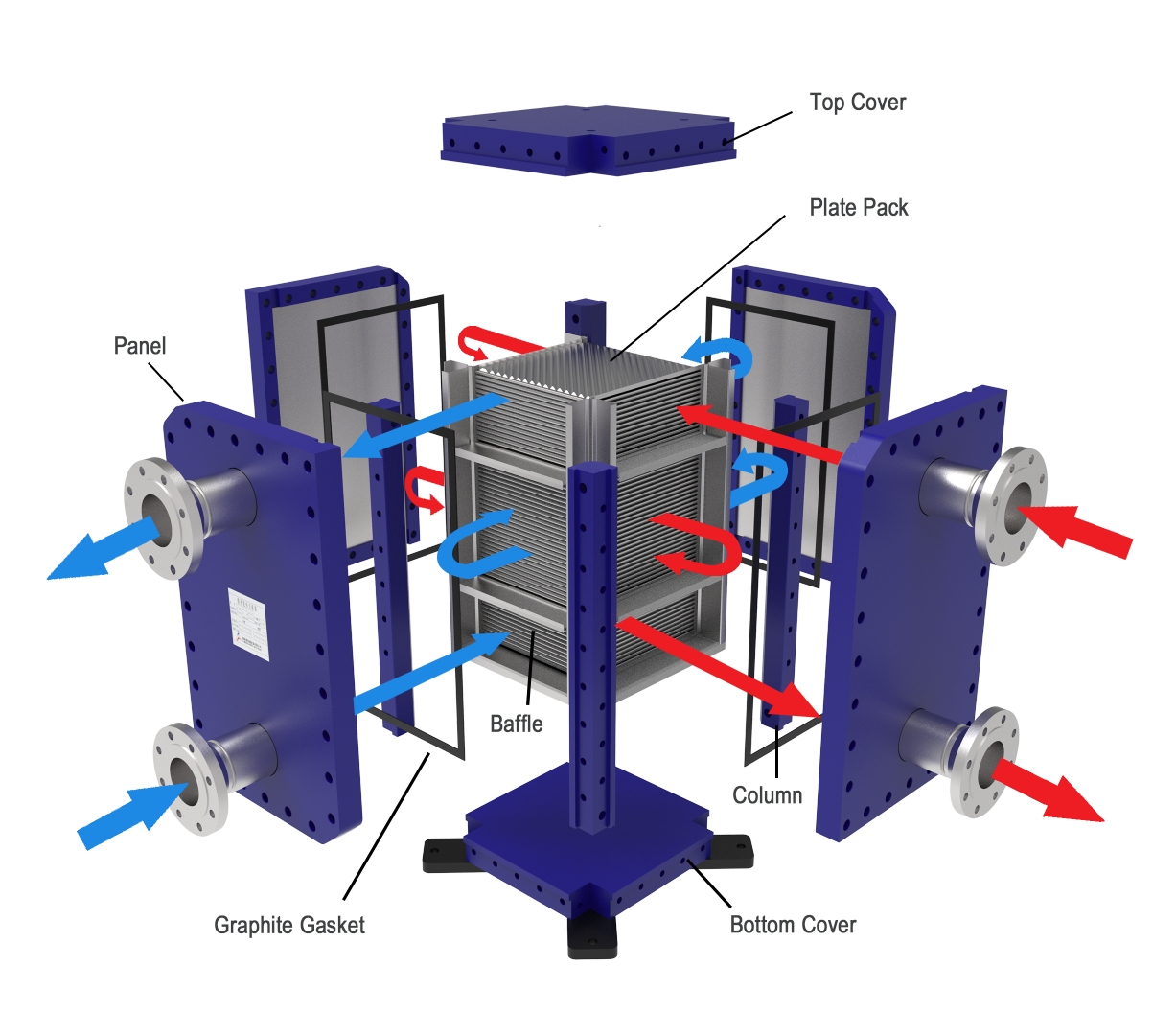

Shanghai Plate Heat Exchanger (SHPHE) and HT-Bloc

Shanghai Plate Heat Exchanger stands out as a leader in the field of welded PHE for high pressure. The HT-Bloc Welded Plate Heat Exchanger is engineered for demanding industrial environments. Its fully welded plate pack eliminates the need for gaskets, which ensures leak-resistant operation even under extreme conditions. The compact structure and modular design allow for easy customization and scalability. The HT-Bloc uses high-quality materials such as stainless steel and titanium, providing excellent corrosion resistance and long-term durability.

The HT-Bloc features a π angle design that prevents dead zones, ensuring consistent thermal performance. Butt welding of plates minimizes the risk of crevice corrosion. The flexible flow configuration supports high thermal efficiency, while the frame can be disassembled for straightforward maintenance and cleaning. The product is certified with CE and ISO standards, and it operates at design pressures up to 3.2 MPa and temperatures from -20°C to 350°C.

Feature/Certification | Description |

|---|---|

Design | Plate pack and frame with welded plates forming channels |

Unique Design | π angle design prevents dead zones |

Corrosion Resistance | Butt welding minimizes crevice corrosion |

Flow Configuration | Flexible, ensures high thermal efficiency |

High-Pressure Tolerance | Compact, designed for high-pressure applications |

Certifications | CE, ISO |

Design Pressure | Up to 3.2 MPa |

Design Temperature | -20°C to 350°C |

Maintenance | Frame can be disassembled for service and cleaning |

The HT-Bloc is a top recommendation for industries seeking a reliable, efficient, and easy-to-maintain welded PHE for high pressure.

Alfa Laval

Alfa Laval is recognized globally for its innovative approach to heat exchanger technology. The Compabloc range is designed for higher pressure applications, offering advanced safety and efficiency. Compabloc+ models operate safely up to 60 bar, maintaining high thermal performance. Both circuits are fully cleanable, which simplifies maintenance and extends service life. Alfa Laval also offers HighP spiral heat exchangers, which feature a double gasket system and a self-supporting internal coil for enhanced reliability under high pressure.

Compabloc range supports high-pressure operations.

Compabloc+ ensures safe operation up to 60 bar.

Full cleanability on both circuits.

HighP spiral exchangers with double gasket system.

Kelvion

Kelvion delivers a broad portfolio of welded plate heat exchangers for high-pressure environments. The company focuses on robust construction and advanced plate designs that maximize heat transfer. Kelvion’s products are suitable for a wide range of industries, including power generation, oil and gas, and chemical processing. Their solutions are known for reliability, energy efficiency, and compliance with international standards.

Tranter

Tranter specializes in fully welded plate heat exchangers that eliminate gaskets, reducing the risk of leaks. This design is essential for handling corrosive or toxic fluids in high-pressure and high-temperature environments. Tranter’s exchangers are built for reliability and long service life, making them a preferred choice in oil and gas, power generation, and other demanding sectors.

SWEP

SWEP is a leader in brazed plate heat exchangers, offering compact and lightweight solutions with superior thermal efficiency. The company tailors its products to meet specific customer requirements, focusing on energy efficiency and reduced maintenance costs. SWEP invests heavily in research and development to stay ahead of market trends and provides robust after-sales support.

Specializes in brazed plate heat exchangers.

Compact size and lightweight.

Superior thermal efficiency.

Strong customer orientation and after-sales support.

VARALKA

VARALKA manufactures welded PHE for high pressure with a focus on durability and performance. Their products are designed for challenging industrial applications, offering high resistance to pressure and temperature. VARALKA emphasizes quality assurance and compliance with global standards, making their exchangers suitable for critical processes.

Valutech Inc

Valutech Inc supplies a wide range of heat exchangers, including welded plate models for high-pressure applications. The company is known for its technical expertise and ability to provide customized solutions. Valutech’s products are used in industries such as HVAC, power generation, and chemical processing, where reliability and efficiency are essential.

Polaris

Polaris ensures quality and performance through precision engineering and strict supplier qualification. The company uses controlled manufacturing steps and continuous quality verification to maintain high standards. Polaris exchangers feature optimized plate designs for enhanced heat transfer and mechanical strength. The double gasket barrier prevents contamination and leakage, while the robust frame construction and glue-free gasket system promote reliability and ease of maintenance.

Precision engineering and strict quality control.

Optimized plate design for high pressure.

Double gasket barrier for safety.

Glue-free gasket system for easy service.

ProThermal Inc

ProThermal Inc offers welded plate heat exchangers designed for high-pressure and high-temperature applications. The company focuses on innovative designs that improve heat transfer efficiency and reduce maintenance requirements. ProThermal’s products are widely used in energy, chemical, and industrial sectors.

SPX Flow

SPX Flow distinguishes itself with advanced testing and certification processes. The company uses non-invasive testing for leakage detection, minimizing downtime and ensuring safety. Their process is eco-friendly, with no chemicals or gases involved. SPX Flow provides rapid on-site assessments and detailed certification, including GPS traceability and contamination volume reporting. The exchangers comply with ISO 9000 standards and are ideal for hazardous media applications.

Feature | Description |

|---|---|

Non-Invasive Testing | Detects leaks without disassembly, minimizing disruption |

Fast Test Process | Quick on-site inspections |

Eco-Friendly | No chemicals or gases used |

Exceptional Sensitivity | Detects leaks below 5 microns |

Rapid Results | Immediate assessment and action |

Test Certification | GPS traceability and contamination reporting |

ISO 9000 Compliance | Seamless documentation |

Hazardous Media Applications | Suitable for ammonia, glycol, and other hazardous substances |

FBM Hudson Italiana

FBM Hudson Italiana is known for its expertise in designing and manufacturing welded plate heat exchangers for high-pressure and high-temperature applications. The company’s products are used in the oil and gas, petrochemical, and power sectors. FBM Hudson Italiana emphasizes custom engineering and compliance with international standards.

Hofmann Heat Exchanger

Hofmann Heat Exchanger offers welded plate heat exchangers with high thermal efficiency and a compact, lightweight design. The exchangers are versatile, handling various fluids, including corrosive and high-temperature liquids. The modular design allows for easy maintenance and cleaning, reducing downtime. Welded construction ensures durability and reliable performance under demanding conditions.

Feature/Benefit | Description |

|---|---|

High Thermal Efficiency | Superior heat transfer rates due to intricate plate design and increased surface area. |

Compact and Lightweight | Smaller footprint ideal for space-constrained installations. |

Versatility | Suitable for various fluids, including corrosive and high-temperature liquids. |

Easy Maintenance | Modular design allows for straightforward cleaning and maintenance, reducing downtime. |

Durability and Reliability | Welded construction ensures robust performance and longevity under demanding conditions. |

When selecting a welded PHE for high pressure, consider the unique strengths and certifications of each manufacturer. SHPHE’s HT-Bloc stands out for its modular design, high-quality materials, and ease of maintenance, making it a top choice for demanding industrial applications.

Comparing Key Features

Pressure Ratings

Pressure rating is a critical factor when selecting welded plate heat exchangers for high-pressure applications. Leading brands design their units to withstand extreme conditions. For example, Tranter’s welded plate heat exchangers can handle design pressures up to 1450 psig (100 barg). Engineers should always verify the maximum allowable working pressure and ensure it matches the requirements of their process. High-pressure tolerance ensures safe operation and long-term reliability.

Check the manufacturer’s stated pressure limits.

Match pressure ratings to your application’s peak operating conditions.

Consider future expansion or process changes that may increase pressure demands.

Materials and Construction

Material selection directly impacts durability, corrosion resistance, and service life. Manufacturers use a range of metals to suit different fluids and environments.

Material | Properties | Applications |

|---|---|---|

Stainless Steel | HVAC, food & beverage, chemical processing | |

Titanium | Chloride resistance, long service life | Seawater desalination, chlor-alkali production |

Nickel Alloys | High temp/corrosion resistance | Chemical processing, power generation, oil & gas |

Duplex Stainless | Niche performance characteristics | Varies by fluid and conditions |

Copper Alloys | Unique properties for specific needs | Specialized applications |

Exotic Metals | Tailored for demanding environments | Where standard materials fail |

Tip: Always select materials based on the fluid composition, temperature, and pressure in your system.

Design and Customization

Customization allows manufacturers to address unique process challenges. Tailored welded PHEs can optimize heat transfer, reduce fouling, and simplify maintenance. Open systems and flat external surfaces make cleaning easier. High turbulence from specialized welding patterns boosts efficiency. No gaskets means higher corrosion resistance and better performance under pressure.

Assess fluid properties to determine heat transfer needs.

Evaluate temperature variations for material compatibility.

Confirm pressure requirements to guide design and construction.

Modular designs, like those from SHPHE, enable easy scaling and adaptation for future needs.

Certifications and Compliance

Certifications guarantee that welded PHEs meet industry standards for safety and quality. Look for products with recognized certifications.

Certification Standard | Description |

|---|---|

ASME Section VIII, Div. 1 | Pressure vessel code |

TEMA Classes B, C, R | Heat exchanger standards |

3-A Sanitary Standards | Hygienic design for food and pharma |

ISO 9001 Quality Management | Quality system certification |

Hydrostatic Pressure Testing | Pressure integrity verification |

Passivation Certification | Corrosion resistance assurance |

Also consider OSHA, EPA, and API compliance for regulatory assurance.

After-Sales Support

Reliable after-sales support ensures optimal performance and longevity. Top manufacturers offer monitoring and optimization systems. These services provide expert guidance, early fault detection, maintenance reminders, cleaning recommendations, and spare part replacements.

Service Type | Description |

|---|---|

Expert guidance, early fault detection, maintenance reminders, cleaning, spare parts, process advice |

For procurement specialists and engineers, prioritize vendors with strong technical support and responsive service teams.

Choosing the Right Manufacturer

Assessing Application Needs

Selecting the right welded plate heat exchanger begins with a clear understanding of your application requirements. Start by identifying the thermal duty, allowable pressure drop, fluid properties, and operating pressure and temperature. These factors determine the suitability of each manufacturer’s offering.

Factor | Description |

|---|---|

Thermal Duty | Sufficient surface area and high U-value for heat transfer |

Allowable Pressure Drop | Avoid excessive energy costs and flow reduction |

Fluid Properties | Match geometry and material to fluid phase and composition |

Operating Pressure & Temperature | Ensure mechanical design fits specific conditions |

Tip: Document your process parameters and desired outcomes before approaching vendors.

Evaluating Manufacturer Capabilities

Review each manufacturer’s strengths in design, material selection, and customization. SHPHE’s HT-Bloc, for example, offers modular construction and high-quality materials, supporting a wide range of industrial needs. Compare technological innovation, compliance with certifications, and flexibility in adapting to unique process demands.

Challenge | Description |

|---|---|

High Initial Investment and Maintenance Complexity | Advanced designs may require higher upfront costs and specialized maintenance. |

Evolving Regulatory Compliance | Regional standards and certifications can complicate procurement. |

Requesting Quotes and Support

When requesting quotes, provide detailed information about your process. Ask about plate technologies, corrugation types, maintenance services, and parts replacement policies.

Investigate plate and corrugation designs.

Inquire about maintenance and cleaning services.

Request details on parts replacement and warranty.

Ask for references and case studies.

Note: Clear communication with vendors ensures accurate proposals and technical support.

Making the Final Selection

Evaluate manufacturers using criteria such as thermal efficiency, material durability, customization, innovation, compliance, support, pricing, and track record.

Criteria | Description |

|---|---|

Thermal Efficiency | Effective heat transfer at high temperatures |

Material Durability | Resistance to corrosion and pressure |

Customization & Flexibility | Ability to tailor solutions |

Technological Innovation | Advanced designs for improved performance |

Compliance & Certifications | Meets safety and environmental standards |

After-Sales Support | Technical support and maintenance |

Pricing & Total Cost of Ownership | Competitive pricing and long-term value |

Track Record & References | Proven reliability and client feedback |

Consider SHPHE and other leading brands for high-pressure applications. Their expertise, certifications, and support can help you achieve safe, efficient, and reliable operations.

The welded plate heat exchanger market features global leaders like Shanghai Plate Heat Exchanger, Alfa Laval, Kelvion, and SPX FLOW, each driving innovation and offering robust solutions for high-pressure demands. Aligning product capabilities with specific application needs streamlines processes and improves operational efficiency:

Benefit | Description |

|---|---|

Matching solutions to needs reduces redundancies and boosts efficiency. | |

Higher Customer Retention | Proper alignment increases satisfaction and long-term reliability. |

Contact SHPHE or other top brands for technical consultations or quotes to ensure the best fit for your next project.

FAQ

What is the main advantage of a welded plate heat exchanger for high-pressure applications?

Welded plate heat exchangers offer superior leak resistance and durability. Their fully welded construction handles high pressures and temperatures, making them ideal for demanding industrial environments.

How do I select the right material for my welded PHE?

Tip: Match the material to your process fluid and operating conditions. Stainless steel suits most applications. Titanium or nickel alloys work best for corrosive or high-temperature fluids.

Can welded PHEs be cleaned easily?

Many welded PHEs feature accessible channels and modular frames. This design allows for mechanical or chemical cleaning, reducing downtime and maintenance costs.

What certifications should I look for when purchasing a welded PHE?

Certification | Purpose |

|---|---|

ASME | Pressure vessel safety |

CE | European compliance |

ISO | Quality management |

Always verify that the product meets industry and regional standards.