Comparing welded block and gasketed plate heat exchangers

You can see clear differences between welded block...

More

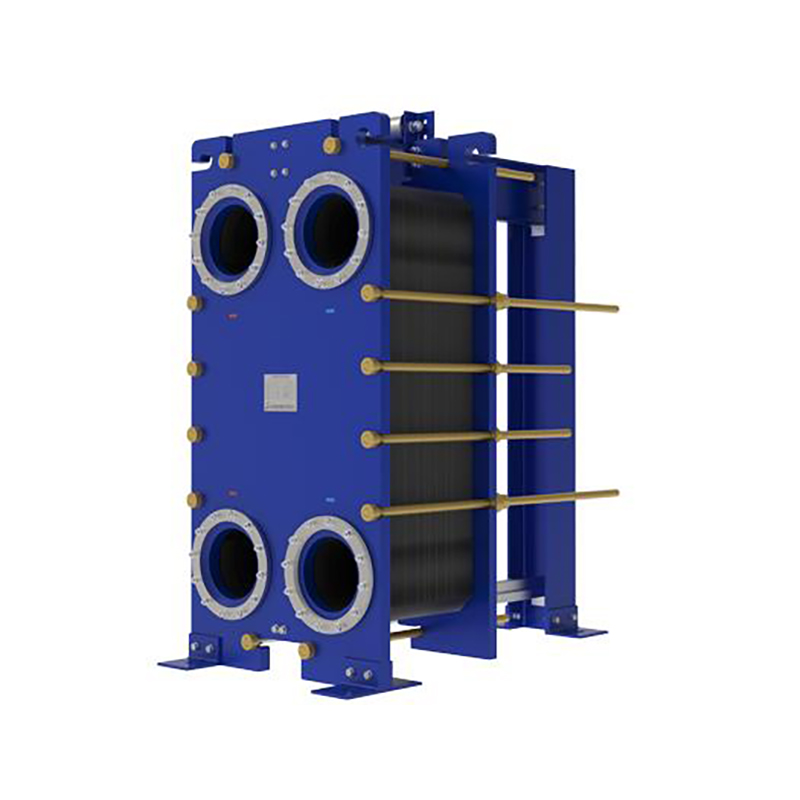

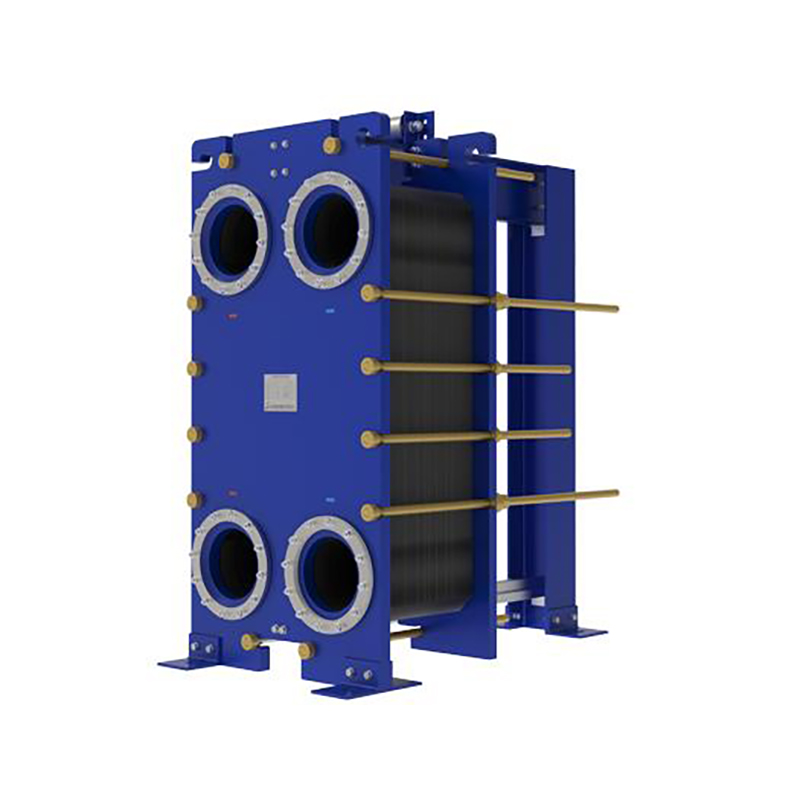

A welded plate and shell heat exchanger is a compact, high-performance thermal transfer device designed for industrial applications requiring efficient heat exchange between fluids. Combining the benefits of traditional shell-and-tube and plate heat exchangers, this hybrid design features corrugated plates welded into a cylindrical shell, offering superior heat transfer efficiency, reduced fouling, and robust construction. These exchangers are widely used in industries such as oil and gas, chemical processing, power generation, and HVAC due to their ability to handle high pressures (up to 100 bar) and temperatures (up to 900°C). Their modular design allows customization for specific operational needs, making them ideal for applications where space, weight, and energy efficiency are critical.

Welded plate and shell heat exchangers are engineered to maximize surface area for heat transfer while minimizing pressure drop. The welded construction eliminates gaskets, reducing maintenance costs and leakage risks compared to gasketed plate heat exchangers. According to industry data, these units achieve thermal efficiencies of 85–95%, significantly outperforming conventional shell-and-tube models. Their compact footprint (up to 80% smaller than equivalent shell-and-tube units) and reduced fluid volume (lowering operational costs) make them a preferred choice for modern industrial systems.

The welded plate and shell heat exchanger operates by transferring heat between two fluids—typically a hot and a cold medium—through a series of corrugated metal plates welded together within a cylindrical shell. The plates create alternating channels for the fluids, ensuring turbulent flow (Reynolds numbers > 2,000) to enhance heat transfer coefficients. One fluid flows through the plate channels, while the other circulates through the shell side, with heat exchanged through the plate material (often stainless steel, titanium, or nickel alloys). The welded design ensures no intermixing, even under high pressure differentials.

In practice, the exchanger’s performance is optimized by plate geometry (chevron angles of 30°–60°), which increases surface area and induces turbulence. Real-world data shows heat transfer coefficients of 3,000–7,000 W/m²K, far exceeding shell-and-tube designs. The absence of gaskets allows operation with aggressive media (e.g., acids or refrigerants) and reduces downtime. Advanced models incorporate laser-welded plates for leak-proof performance in critical applications like LNG processing or nuclear power plants. Their scalability (from 0.1 m² to 1,500 m² surface area) and adaptability to multi-pass configurations make them versatile for diverse thermal duties.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

You can see clear differences between welded block...

More

Plate heat exchanger gaskets perform 5 key roles: ...

MoreAPI 662 defines standards for plate heat exchanger...

More

A gasket in heat exchanger seals surfaces, blocks ...

More

Industries in 2025 achieve higher efficiency by ad...

More

What is a heat exchanger? It's a device that trans...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe welded plate and shell heat exchanger is extremely efficient and durable. It has significantly improved our plant's thermal performance.

Emily Johnson

Process EngineerGreat product with excellent heat transfer capabilities. Installation was straightforward, and it requires minimal maintenance.

Michael Brown

HVAC SpecialistThis heat exchanger outperforms traditional models in both efficiency and compact design. Highly recommended for commercial HVAC systems.

Sarah Davis

Energy ConsultantReliable and energy-efficient solution for industrial applications. The welded plate design ensures long-term performance with low pressure drop.