Welded Plate Heat Exchanger Application In The Oil And Gas Industry

Heat exchange plays a vital role in oil and gas operations, ensuring safe and efficient processing. Complex fluids, such as slurries and viscous liquids, often require advanced equipment to prevent blockages and maintain reliability. The Welded Plate Heat Exchanger offers a modern solution for these demanding environments. This technology uses robust design and high-performance materials to handle harsh conditions and challenging fluids with ease.

Key Takeaways

· Welded Plate Heat Exchangers offer high heat transfer efficiency with a compact, lightweight design that saves space and reduces weight compared to traditional exchangers.

· Their welded construction and corrosion-resistant materials allow them to handle high pressures, extreme temperatures, and harsh fluids common in oil and gas operations.

· Optimized flow designs and self-cleaning features prevent blockages and fouling, ensuring reliable performance and easier maintenance.

· These exchangers support precise temperature control and energy savings across upstream, midstream, and downstream oil and gas processes.

· Compared to shell-and-tube exchangers, welded plate heat exchangers provide better thermal efficiency, smaller footprints, and simpler maintenance, making them ideal for demanding environments.

Welded Plate Heat Exchanger Overview

Design Features

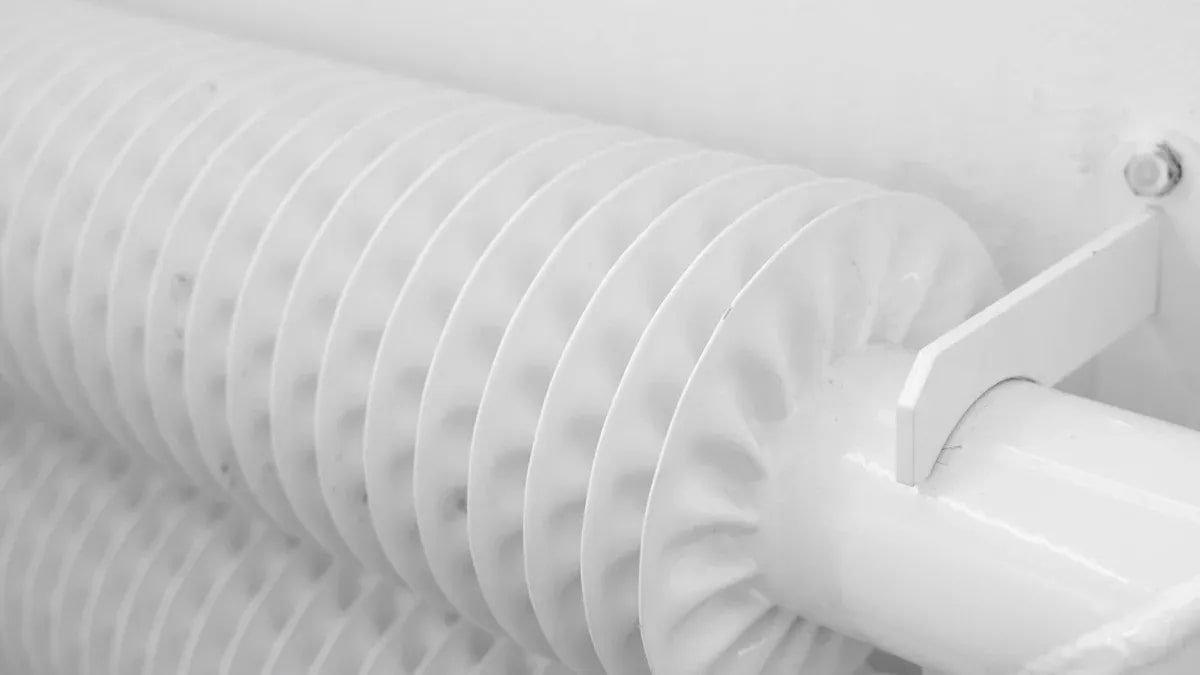

The Welded Plate Heat Exchanger stands out due to its innovative engineering and robust construction. Manufacturers design these exchangers with pillow plates welded into cassettes, forming an accordion-like core. This structure eliminates the need for gaskets, allowing the unit to withstand pressures up to 1,450 psig and temperatures from –50°F to 1,650°F. The compact design replaces large shell-and-tube exchangers, reducing the footprint from 100 ft² to just 8 ft² and lowering the weight from 7 tons to less than 1 ton.

Feature | Benefit |

Chevron Plates | High turbulence, improved heat transfer |

Welded Construction | No gaskets, high pressure and temperature resistance |

Compact Footprint | Space-saving, lightweight |

Optimized Flow Design | Enhanced efficiency, reduced fouling |

How It Works

A Welded Plate Heat Exchanger operates by directing two fluids through alternating channels formed by the welded plates. The chevron pattern on the plates creates turbulence, which increases the heat transfer coefficient and reduces the risk of fouling. Enhanced turbulence and secondary flows boost efficiency and lower flow resistance. Computational Fluid Dynamics (CFD) simulations help engineers visualize and optimize flow distribution, ensuring maximum performance.

Operators monitor temperature, flow, and pressure using sensors, which allows for early detection of irregularities and data-driven adjustments. Predictive maintenance based on sensor data minimizes downtime and extends equipment lifespan. Proper insulation reduces heat loss, making sure thermal energy stays within the process. The design supports easy cleaning and maintenance, which is essential for continuous operation in demanding oil and gas environments.

· Key performance indicators include heat transfer coefficient, pressure drop, pumping power, and Nusselt number.

· Multi-objective optimization has identified ideal structural parameters, such as a chevron angle of 45°, corrugation pitch of 15 mm, and corrugation height of 3 mm.

· Comparative studies show that Welded Plate Heat Exchangers achieve over 20% improvement in performance evaluation criteria compared to standard models.

Applications in Oil and Gas

Upstream Processes

Oil and gas extraction begins with upstream operations. These processes include crude oil separation, gas dehydration, and produced water treatment. Operators often encounter fluids with high viscosity, suspended solids, or corrosive properties. The Fully Welded Plate Heat Exchanger addresses these challenges with its robust design and advanced materials.

· Stainless steel and nickel alloys resist corrosion from sour gas and aggressive chemicals.

· Optimized channel geometry prevents blockages from slurries and fiber-containing fluids.

· Integrated cleaning-in-place (CIP) systems allow for efficient removal of fouling without disassembly.

Operators benefit from precise temperature control, which is critical for phase changes such as condensation and vaporization. Enhanced heat transfer efficiency reduces energy consumption and supports heat recovery from waste streams. Custom sizing and configuration ensure the equipment fits within tight spaces on drilling platforms or well pads. These improvements lead to higher operational reliability, lower maintenance costs, and better process yields.

Note: Advanced manufacturing techniques, such as laser welding, further improve durability and sustainability in upstream environments.

Midstream and Offshore

Midstream operations focus on transporting, storing, and conditioning oil and gas. Offshore platforms and pipelines require reliable heat exchange solutions to maintain product quality and system safety. The Welded Plate Heat Exchanger excels in these settings due to its compact footprint and resistance to harsh marine conditions.

Operators monitor fouling factors daily using specialized software. This approach enables early detection of fouling events and supports timely cleaning interventions. A large oil refinery demonstrated that tracking performance data helps identify the right time for cleaning, minimizing downtime and maintaining capacity. Key performance indicators, such as energy efficiency and reliability, guide operational decisions.

· Analysis of operational data optimizes cleaning intervals.

· Proper heat exchanger sizing and flow dynamics reduce pressure drops and energy loss.

· Corrosion-resistant construction extends equipment lifespan in offshore environments.

These features ensure steady operation, reduce the risk of leaks, and support long-term reliability in midstream and offshore applications.

Downstream and Petrochemicals

Downstream operations involve refining crude oil and producing petrochemicals. These processes demand precise temperature control and efficient heat recovery. The TP Welded Plate Heat Exchanger supports critical tasks such as preheating feedstocks, cooling process streams, and condensing vapors.

Refineries often handle fluids with high fouling potential, including heavy oils and fiber-laden slurries. The exchanger’s simplified channel geometry and integrated self-cleaning mechanisms prevent blockages and maintain high thermal performance. Operators use corrosion- and wear-resistant materials to extend equipment life and reduce maintenance needs.

· Heat exchangers enable energy recovery from hot process streams, lowering operating costs.

· They help maintain product quality by ensuring fluids reach target temperatures.

· Optimized flow distribution minimizes pressure drop and maximizes heat transfer.

These advantages contribute to sustainability goals by reducing emissions and energy use. The Welded Plate Heat Exchanger provides a reliable, efficient solution for complex downstream and petrochemical operations.

Advantages in Industry

Efficiency and Compactness

The oil and gas industry demands equipment that delivers high thermal efficiency while saving valuable space. Welded PHE meet these requirements with their innovative plate design and compact structure. The plates create a large surface area for heat transfer within a small footprint. This design allows operators to install the units in tight spaces, such as offshore platforms or crowded refinery floors.

Studies on thermal performance highlight the importance of optimizing the heat transfer envelope. By maintaining high heat transfer coefficients, these exchangers help reduce energy consumption and improve overall process efficiency. Advanced simulation tools, like SMARTEYE, model thermal loads and validate the impact of compact designs on energy use. Flexible space utilization strategies, such as placing exchangers closer to process points, further enhance energy performance and reduce heating demand. Operators benefit from lower energy use intensity and improved heating efficiency, supporting both operational and sustainability goals.

Tip: Compact heat exchangers not only save space but also simplify installation and integration into existing systems.

Durability and Reliability

Durability stands as a critical factor in oil and gas operations, where equipment faces high pressures, extreme temperatures, and corrosive fluids. Welded Plate Heat Exchangers use corrosion-resistant alloys, such as stainless steel and nickel-based materials, to withstand harsh environments. These materials help prevent stress corrosion cracking, a common issue in chloride-rich and high-pressure conditions.

· Stress corrosion cracking can compromise structural integrity, especially under high pressure and temperature.

· Operators select alloys and apply protective coatings to manage corrosion and extend equipment life.

· Inspection methods, including Ultrasonic Testing and Radiographic Testing, detect internal corrosion and cracks early.

· Design features, such as smooth fluid flow and crevice-free construction, further reduce corrosion risks.

Protective coatings and alloying elements like chromium and aluminum enhance resistance to high-temperature corrosion. These strategies ensure that the heat exchanger maintains performance and reliability, even in the most demanding applications.

Maintenance and Cleaning

Efficient maintenance and cleaning routines are essential for continuous operation in oil and gas facilities. Welded Plate Heat Exchangers support these needs with integrated Cleaning-in-Place (CIP) systems and simplified channel geometries. Operators use advanced monitoring tools to track performance indicators, such as heat transfer coefficients and pressure drops, which signal when cleaning is necessary.

· Simulation programs calculate fouling costs and determine optimal cleaning intervals.

· Routine data collection helps operators assess performance degradation and cleaning effectiveness.

· Cleaning methods include chemical cleaning, water-lancing, and online cleaning, with chemical cleaning often restoring heat exchange capacity efficiently.

· Operators use start-of-run baselines and post-cleaning audits to verify cleaning success and adjust maintenance schedules.

Monitoring software Smart Eye and trending tools allow teams to detect fouling early, minimizing downtime and maintaining throughput. Clear communication of performance metrics supports informed maintenance decisions and helps justify cleaning work. By integrating these practices, operators achieve energy optimization and reduce unplanned outages, ensuring reliable production.

Comparison with Other Exchangers

Shell-and-Tube vs. Welded Plate Heat Exchanger

Shell-and-tube heat exchangers have served the oil and gas industry for decades. They use bundles of tubes inside a shell to transfer heat between fluids. In contrast, plate heat exchangers use stacked plates to create many small channels for fluid flow. This design difference leads to significant performance advantages.

The table below highlights key differences in thermal efficiency:

Exchanger Type | Heat Transfer Coefficient (W/(m²·K)) | Footprint | Maintenance |

Shell-and-Tube | 150 – 1200 | Large | More complex |

Plate (Welded) | 1000 – 4000 | Compact | Easier, modular |

Plate heat exchangers achieve higher heat transfer coefficients, which means they transfer heat more efficiently. Their compact size saves valuable space, especially in offshore or crowded facilities. Operators can expand capacity by adding plates, a flexibility not possible with shell-and-tube units. Maintenance is also simpler, as the modular design allows for quick inspection and cleaning.

Note: Plate heat exchangers support closer temperature approaches, which improves heat recovery and energy savings.

Gasketed Plate vs. Welded Plate

Gasketed plate heat exchangers use gaskets between plates to seal channels. This design allows for easy disassembly and cleaning. However, gaskets may limit the unit’s ability to handle high pressures or aggressive chemicals. Welded plate designs remove the need for gaskets, making them suitable for harsh conditions and challenging fluids. They resist leaks and withstand higher pressures and temperatures, which is essential in demanding oil and gas applications.

Selection Considerations

Selecting the right heat exchanger depends on several factors. Engineers must consider the type of heat extraction technology, fluid properties, and operational requirements. Numerical simulations help predict thermal recovery and optimize production parameters. Accurate performance data is critical, but testing can be costly and complex in industrial settings.

Key selection criteria include:

· Type of heat extraction: open-loop or closed-loop systems

· Fluid temperature: above 74 °C for power generation, below 74 °C for heating

· Economic factors: cost savings from reusing existing infrastructure

· Thermal performance: higher coefficients of performance (COP) indicate better efficiency

· Operational flexibility: ability to expand or modify capacity as needed

· Complexity of installation and maintenance

Tip: Using advanced fluids, such as Cu/water nanofluids, can boost outlet temperatures and improve efficiency.

Real-World Use Cases

Project Examples

Many oil and gas companies have adopted advanced plate heat exchangers to improve efficiency and reliability in demanding environments. Onshore refineries and offshore platforms both require compact, high-performance solutions. SHPHE has delivered custom-engineered heat exchangers for projects facing high temperatures, pressures, and challenging fluids.

The following table highlights key performance metrics observed in real-world oil and gas applications:

Performance Metric | Result / Observation |

Operating Conditions | Temperatures up to 500 °C, Pressure up to 32 MPa |

Heat Transfer Rate Improvement | Up to 20% increase with corrugated plate design |

Maximum Effectiveness | 0.48 (with water as working fluid) |

Pressure Drop | Negligible in optimized designs |

Compactness | Requires less space than conventional exchangers |

Application | Reliable operation in ammonia synthesis columns and other harsh processing settings |

SHPHE has partnered with leading oil and gas companies to implement these solutions in ammonia synthesis columns and pipeline heating systems. These projects demonstrate operational reliability and energy efficiency, even under extreme conditions.

Lessons Learned

Field experience shows that plate heat exchangers deliver measurable benefits across a range of oil and gas processes. Operators report up to 20% higher heat transfer rates and significant space savings compared to traditional tube exchangers. Mathematical models, validated by industrial tests, confirm these results in harsh environments.

A case study in industrial drying revealed that optimizing heat exchanger design can increase the Specific Moisture Extraction Rate by 44%, reduce drying time by 45%, and cut total energy use by over 21%. Swirl-inducing techniques, such as corrugated plates, further enhance fluid mixing and heat transfer. These improvements help operators achieve higher efficiency and lower operational costs.

SHPHE’s commitment to innovation and collaboration with industry leaders ensures that each solution meets the unique challenges of oil and gas operations. Their expertise supports reliable, efficient, and sustainable production worldwide.

Welded plate heat exchangers deliver strong performance in oil and gas operations. Their benefits include:

· High heat transfer efficiency and compact, modular designs

· Corrosion resistance with advanced materials

· Reliable operation under high pressures and temperatures

· Reduced fouling and easier maintenance

Industry trends show rising demand for energy-efficient solutions, growth in Asia-Pacific, and new innovations in materials and smart monitoring. These advances will help operators meet stricter environmental standards and improve process reliability.

FAQs

What makes welded plate heat exchangers suitable for harsh oil and gas environments?

Welded heat exchangers use corrosion-resistant materials and robust welded construction. This design allows them to handle high pressures, extreme temperatures, and aggressive fluids commonly found in oil and gas operations.

How do operators clean welded plate heat exchangers?

Operators use integrated Cleaning-in-Place (CIP) systems. These systems circulate cleaning solutions through the exchanger, removing fouling and deposits without disassembly. This process saves time and reduces maintenance costs.

Can welded plate heat exchangers handle fluids with solids or fibers?

Yes. Optimized channel geometry and self-cleaning features prevent blockages from slurries, viscous fluids, or fiber-containing streams. This design ensures reliable operation even with challenging process fluids.

What are the main benefits compared to shell-and-tube exchangers?

· Higher thermal efficiency

· Smaller footprint

· Easier maintenance

Welded plate heat exchangers deliver better heat transfer and require less space. Operators also benefit from faster cleaning and lower downtime.

Are welded plate heat exchangers customizable for specific applications?

Engineers can tailor plate patterns, materials, and channel sizes to match process requirements. This flexibility ensures optimal performance for each oil and gas application.

If you need further consultation and discussion, please feel free to contact us.

Email: info@shphe.com

WhatsApp /Cell: +86 15201818405