Welded Plate Heat Exchangers A Deep Dive into Their Benefits

Unmatched Durability in Extreme Operating Conditions

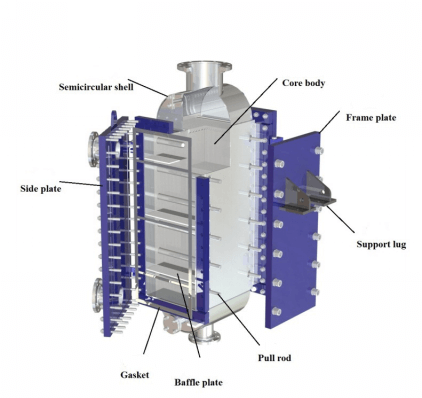

A welded plate heat exchanger excels in harsh industrial environments. Its design provides superior durability where other technologies might fail. This resilience stems from its fundamental construction, which eliminates common weak points and uses robust materials engineered for extreme duty.

Gasket-Free Design for Leak-Proof Performance

Traditional heat exchangers often fail at the gasket seals. Welded designs eliminate this vulnerability entirely. Manufacturers use advanced welding techniques to create a permanent, leak-proof bond between the plates. These methods include:

·Laser Welding: This technique offers high energy density. It creates a very strong seal with a minimal heat-affected zone.

·Brazing: This process uses a filler metal melted at high temperatures in a vacuum furnace. It forms a solid, inseparable bond across the entire plate pack.

These processes ensure that aggressive or high-pressure fluids remain securely contained, preventing costly leaks and enhancing plant safety.

Robust Construction for High Pressure and Temperature

Engineers construct these units from high-grade materials like stainless steel and titanium. Stainless steel is a primary choice for demanding oil and gas applications. Titanium provides exceptional resistance in highly corrosive environments. This robust construction allows the exchangers to operate under extreme conditions.

A welded plate heat exchanger can typically handle design pressures from a full vacuum up to 50 barg (725 psig) and temperatures ranging from -50°C to 450°C (-58°F to 842°F).

Resistance to Thermal and Pressure Fatigue

Industrial processes often involve frequent changes in temperature and pressure. These fluctuations can cause metal fatigue over time. Welded plate heat exchangers are specifically designed to resist this stress. Testing demonstrates their ability to endure tens of thousands of pressure cycles without failure. This resilience ensures long-term operational reliability and minimizes the risk of unexpected downtime, even in processes with constant thermal cycling.

The Superior Thermal Efficiency of a Welded Plate Heat Exchanger

A welded plate heat exchanger achieves exceptional thermal performance. Its design maximizes heat recovery and minimizes energy waste. This efficiency translates directly into lower operational costs and a more sustainable industrial process. The unit's core components work together to create a highly effective system for thermal management.

Maximizing Heat Transfer with Corrugated Plates

The corrugated plates are the key to the exchanger's high efficiency. These plates feature special patterns, such as chevron or herringbone designs. The patterns create a turbulent, tortuous flow path for the fluids. This turbulence breaks up the boundary layer and dramatically increases the heat transfer coefficient. Engineers can optimize performance by adjusting the chevron angle; steeper angles boost heat transfer but also increase pressure drop. This allows for a tailored design that balances thermal duty with pumping power requirements.

Achieving Closer Temperature Approaches

High efficiency allows these exchangers to achieve very close temperature approaches, often as low as 1°C (2°F). A close temperature approach means the outlet temperature of the cold fluid can get very near the inlet temperature of the hot fluid. This capability maximizes heat recovery from process streams.

Note: While a closer approach improves thermal efficiency and can reduce utility costs, it requires a larger heat transfer area. This increases the initial capital cost of the unit, creating a trade-off between upfront investment and long-term energy savings.

Optimizing Energy Consumption

The combination of high heat transfer rates and close temperature approaches significantly reduces energy consumption. By recovering more waste heat, facilities can decrease their reliance on external utilities like steam or cooling water. This optimization leads to substantial cost savings and a smaller environmental footprint. Industries report significant performance gains:

·Crude oil preheat trains can achieve a potential energy reduction of 25%.

·Ammonia synthesis and LiBr-water absorption systems show improved operational performance.

·Refineries benefit from superior thermal performance and better fouling mitigation.

Compact Footprint: A Major Space-Saving Advantage

The compact design of a welded plate heat exchanger offers a significant advantage in industrial settings where space is a premium. This smaller size directly impacts project timelines and budgets, providing flexibility that traditional equipment cannot match. It allows engineers to optimize plant layouts and simplify retrofitting projects.

Reducing Installation Footprint and Costs

The smaller size and lower weight of these units directly reduce installation costs. Unlike bulky shell-and-tube exchangers, they do not require extensive structural support or large, dedicated floor space. Their lightweight nature simplifies logistics and handling. This design allows for creative installation solutions, such as placement on top of distillation columns or suspension from existing structures. This flexibility solves common installation challenges in crowded plants and lowers the overall capital cost of new projects.

High Power Density Compared to Shell-and-Tube

These exchangers deliver impressive thermal performance from a remarkably small volume. This high power density is a key differentiator. Research shows these units require only 20-30% of the installation footprint compared to a shell-and-tube exchanger with the same thermal capacity. This represents a 70-80% reduction in physical space. The table below highlights the dramatic difference in scale.

| Feature | Plate Heat Exchanger | Shell & Tube Heat Exchanger |

|---|---|---|

| Size / Weight | Approximately 1/3 to 1/5 | Large and heavy |

| Footprint | Small, requires minimal space | Large, needs extensive area |

This space-saving capability is crucial for offshore platforms, modular process skids, and dense urban energy systems. It frees up valuable plant real estate for other critical equipment.

Lowering Lifecycle Costs Through Reduced Maintenance

A key financial benefit of these exchangers is their significantly reduced maintenance burden. This advantage directly lowers long-term operational expenses and improves plant availability. The robust, fully welded design minimizes the need for routine service, translating into substantial savings over the unit's lifespan.

Eliminating Gasket Replacement and Downtime

The gasket-free construction of a welded unit is its greatest maintenance advantage. Traditional exchangers require periodic gasket replacement, a labor-intensive process that causes costly downtime. Eliminating gaskets removes this entire maintenance cycle. This design choice prevents unexpected leaks from gasket failure and frees up maintenance teams to focus on other critical tasks, enhancing overall plant productivity.

Streamlined Cleaning-in-Place (CIP) Procedures

The turbulent flow that enhances thermal efficiency also helps keep the plates clean. For necessary cleaning, operators use a simple Cleaning-in-Place (CIP) procedure without disassembling the unit. This process typically involves:

1.Draining and isolating the heat exchanger.

2.Flushing both sides with water until it runs clear.

3.Circulating a cleaning agent, such as an alkaline solution for organic fouling or a mild acid for mineral scale.

4.Performing a final water flush to remove all chemicals.

Calculating the Total Cost of Ownership

A true assessment of an exchanger's value requires calculating its Total Cost of Ownership (TCO). This analysis looks beyond the initial purchase price.

Note: A comprehensive TCO calculation provides a complete financial picture, factoring in both initial and long-term expenses.

Key factors in a TCO calculation include:

·Initial purchase and installation costs

·Energy consumption over the lifecycle

·Maintenance and cleaning requirements

·Potential downtime costs

A techno-economic assessment in the CO2 capture industry showed that different heat exchanger types yield vastly different TCO results, underscoring the need for application-specific analysis.

Versatility Across Demanding Industrial Applications

The robust design of a welded plate heat exchanger makes it suitable for a wide array of demanding industrial duties. Its ability to handle extreme temperatures, high pressures, and aggressive fluids allows it to excel where other technologies fall short. This versatility ensures reliable performance across the chemical, energy, and HVAC sectors.

Chemical Processing and Aggressive Media

In chemical manufacturing, equipment must safely handle highly corrosive substances. The gasket-free design of these exchangers provides a secure, leak-proof solution for managing aggressive media. Manufacturers use specialized materials to ensure long-term reliability.

·Hastelloy plates offer extreme resistance to acids like hydrochloric acid.

·Titanium is used for other highly corrosive fluids.

This makes them ideal for duties such as cooling sulfuric acid or managing various solvents and caustics. For example, Vitherm's Weldpack® unit, using Hastelloy C-276 plates, successfully serves as an H2SO4 cooler, demonstrating its suitability for harsh chemical environments.

Oil and Gas Refining

Refineries and petrochemical plants rely on efficient thermal management for processes like crude oil distillation and hydrocarbon processing. Spiral plate heat exchangers, a type of welded unit, are frequently used to heat or cool crude oil and separate its components. Their robust construction is perfect for heating, cooling, condensation, and evaporation duties involving hydrocarbons. This ensures dependable operation in critical applications, both onshore and offshore, from dehydration to desulfurization.

HVAC and District Energy Systems

These exchangers play a vital role in modern energy infrastructure. In district heating networks, they act as efficient interfaces, transferring heat from a central source to secondary building circuits. This isolates pressure zones and prevents contamination.

Application Highlight: They are also used to recover industrial waste heat or harness geothermal energy. By enabling a close temperature approach, they maximize energy recovery from low-grade heat sources, improving overall system efficiency and promoting energy conservation.

Their compact size and high thermal transfer coefficients make them perfect for prefabricated heat exchange stations, simplifying installation and reducing costs.

A welded plate heat exchanger delivers an excellent combination of durability, efficiency, and compact design. It minimizes maintenance needs and maximizes thermal performance, providing a lower total cost of ownership. For applications where performance under pressure is essential, a welded plate heat exchanger represents a strategic investment for long-term operational success.

FAQ

What is the main difference between welded and gasketed units?

Welded units use permanent welds instead of gaskets. This design prevents leaks and handles higher pressures and temperatures. It provides superior reliability for demanding industrial duties.

How are welded plate heat exchangers cleaned?

Operators clean these units without disassembly. They use a Cleaning-in-Place (CIP) process. This involves circulating cleaning chemicals to remove fouling and restore performance efficiently.

Is a welded plate heat exchanger more expensive?

The initial purchase price may be higher. However, its lower maintenance needs and higher energy efficiency result in a significantly reduced Total Cost of Ownership (TCO) over its lifespan.