Why Choose a Welded Plate Exchanger for Your Plant?

Achieve Superior Durability and Plant Safety

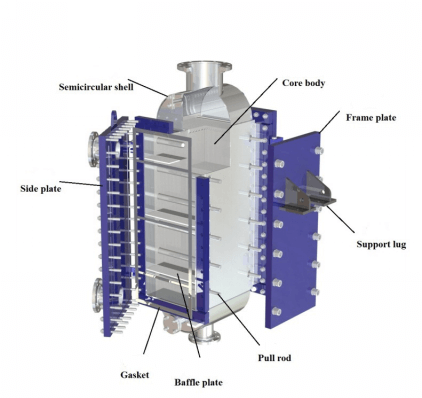

Industrial plants prioritize durability and safety above all else. A welded plate exchanger delivers exceptional performance in both areas. Its robust design directly addresses common points of failure found in other heat exchanger types, creating a more reliable and secure operating environment.

Eliminate Gasket-Related Failures

Traditional gasketed exchangers have a significant vulnerability: the gaskets themselves. These components are frequent sources of maintenance issues and process failures. Gaskets can fail due to:

·Chemical attack from aggressive fluids

·Degradation from high temperatures

·Failure under high pressure

The welded design completely removes gaskets from the plate pack. This change eliminates the primary cause of leaks and cross-contamination, ensuring uninterrupted operation and enhancing plant safety.

Withstand Extreme Thermal Cycles

Many industrial processes involve rapid and frequent temperature changes. These thermal cycles cause materials to expand and contract, creating stress that can lead to fatigue and failure. The strong, welded construction of the plates allows the unit to absorb these stresses effectively. This resilience prevents cracks and extends the equipment's service life, even in the most demanding cyclic duties.

Ensure Leak-Proof Containment

The integrity of the process fluid is critical. Any leak can result in safety hazards, environmental damage, and costly product loss. A welded plate exchanger creates a fully sealed, robust unit that provides superior containment.

Maximize Thermal Performance and Efficiency

A welded plate exchanger is engineered not just for durability but for outstanding thermal performance. Its design principles directly translate into higher efficiency, a smaller physical size, and lower operational costs for the plant. These advantages make it a smart investment for optimizing industrial processes.

Boost Heat Transfer Rates

The core of the exchanger's efficiency lies in its plate design. The corrugated patterns on each plate create a turbulent flow, even at low fluid velocities. This turbulence is key to maximizing heat transfer.

·It disrupts the stagnant "boundary layer" of fluid that typically clings to flat surfaces.

·It forces more of the process fluid to make contact with the heat transfer surface.

·This action significantly increases the overall heat transfer coefficient (U-value).

A higher U-value means the equipment transfers heat much more effectively than other exchanger types of a similar size.

| Feature | Welded Plate Exchanger | Traditional Shell-and-Tube |

|---|---|---|

| Flow Path | Turbulent, winding path | Smoother, linear path |

| Heat Transfer | Very High (High U-value) | Moderate (Lower U-value) |

| Efficiency | Superior | Standard |

Reduce Your Plant's Footprint

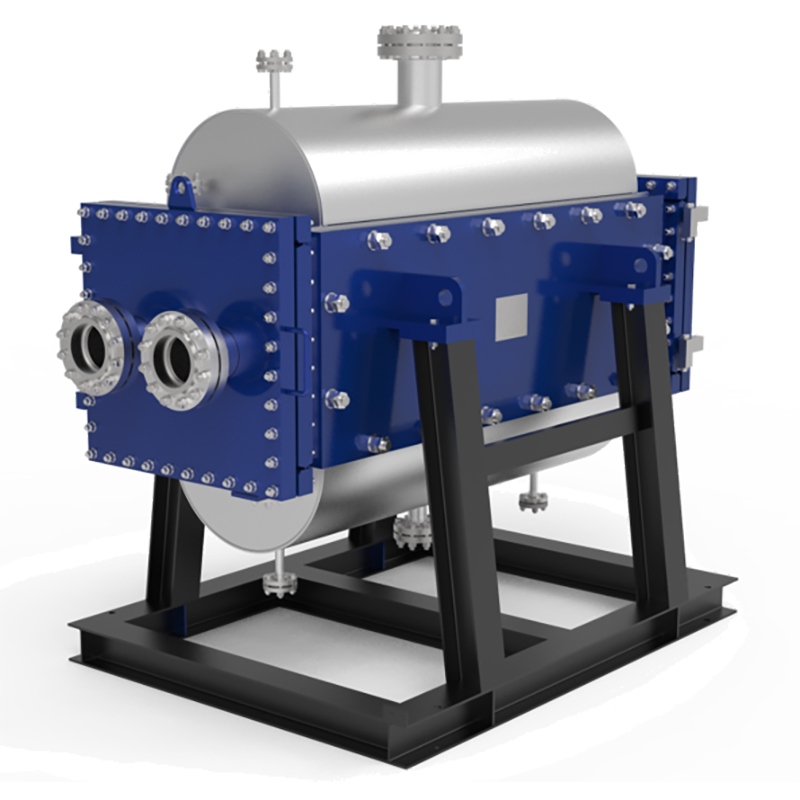

High thermal efficiency has a direct impact on equipment size. Because it transfers heat so effectively, a welded plate exchanger requires significantly less surface area to perform the same duty as a bulkier shell-and-tube unit.

This compact design delivers several practical benefits for any industrial facility:

·Saves Valuable Space: It frees up critical floor space for other essential equipment.

·Lowers Structural Costs: Its lighter weight reduces the need for expensive foundations and support structures.

·Simplifies Installation: The smaller size makes it easier to transport, rig, and install, especially in tight or existing spaces.

This reduction in size and weight can lead to substantial savings in project capital costs.

Lower Energy Consumption

An efficient heat exchanger directly reduces a plant's energy usage and operational expenses. The design achieves this in two primary ways.

First, its high efficiency enables a very close temperature approach. This means the outlet temperature of the cold fluid can get very close to the inlet temperature of the hot fluid. This capability is crucial for maximizing heat recovery from process or waste streams, turning otherwise wasted energy into a valuable resource.

Note: Maximizing heat recovery minimizes the need for additional energy from utilities like steam or electricity, directly cutting operational costs and supporting plant sustainability goals.

Second, the optimized flow channels achieve high heat transfer without demanding excessive pumping power. The unit is designed to balance thermal performance with a low pressure drop, ensuring the system runs efficiently without overburdening pumps and consuming extra electricity.

Reduce Total Cost of Ownership with a Welded Plate Exchanger

A smart investment in plant equipment considers the total cost of ownership (TCO), not just the initial purchase price. TCO includes all expenses over the equipment's entire lifecycle, from installation and operation to maintenance and eventual replacement. A welded plate exchanger excels in this area, delivering significant long-term savings that make it a financially sound choice for any industrial facility.

Minimize Fouling and Downtime

Fouling, the buildup of unwanted deposits on heat transfer surfaces, is a major cause of inefficiency and costly downtime in industrial plants. The design of a welded plate exchanger directly combats this problem.

The corrugated plates create a highly turbulent flow path for fluids. This turbulence scours the heat transfer surfaces, preventing particles from settling and building up. This self-cleaning effect keeps the exchanger operating at peak efficiency for longer periods.

Benefit: This resistance to fouling means fewer scheduled cleanings are necessary. The result is a direct increase in plant uptime and productivity, as processes can run uninterrupted for extended intervals. Less frequent cleaning also reduces labor costs and the use of cleaning chemicals.

Cut Gasket Replacement Costs

Gaskets are a significant operational expense and a common failure point in traditional plate-and-frame exchangers. A fully welded design eliminates these costs entirely. There are no gaskets within the plate pack to replace, inspect, or maintain.

This design change provides several financial advantages:

·Zero Gasket Costs: Plants save money by never needing to purchase expensive replacement gasket sets.

·Reduced Labor Expenses: Maintenance teams do not spend time and resources opening units to replace failed or aging gaskets.

·Eliminated Downtime for Gasket Service: Production does not stop for gasket-related maintenance, maximizing plant output.

The table below illustrates the clear cost advantage over the equipment's lifespan.

| Cost Factor | Gasketed Plate Exchanger | Welded Plate Exchanger |

|---|---|---|

| Gasket Purchase | Recurring Expense | None |

| Maintenance Labor | High (for replacement) | Minimal (for external inspection) |

| Associated Downtime | Significant | None |

Lower Installation and Material Costs

The superior thermal efficiency of a welded design allows it to achieve the same heat transfer duty with a much smaller footprint and lighter weight compared to traditional shell-and-tube units. This compactness translates directly into lower upfront costs.

First, installation becomes simpler and less expensive.

·The smaller size makes transportation and rigging easier, especially in tight or retrofitted spaces.

·The lighter weight reduces the need for heavy-duty cranes, extensive foundations, or complex structural supports.

Second, the efficient design reduces material requirements. Because less surface area is needed, the unit requires less raw material, such as stainless steel or other exotic alloys. This material efficiency makes the equipment more affordable, particularly when expensive, corrosion-resistant materials are necessary for the process.

A welded plate exchanger delivers superior durability, high thermal efficiency, and enhanced safety. This technology provides a lower total cost of ownership, making it the optimal choice for plants needing reliable heat transfer in challenging industrial processes.

FAQ

What are the primary applications for a welded plate exchanger?

They are ideal for high-pressure, high-temperature duties. Industries like chemical processing, oil and gas, and HVAC use them for handling aggressive or critical fluids safely and efficiently.

Can a welded plate exchanger be cleaned?

Yes, cleaning is performed using a clean-in-place (CIP) process. This method circulates cleaning solutions through the unit without disassembly, which efficiently removes internal fouling and restores performance.

How does it compare to a shell-and-tube exchanger?

It provides higher thermal efficiency in a much smaller footprint. This compact design saves valuable plant space and lowers installation costs compared to a shell-and-tube unit.