Why Plate Heat Exchangers Are Essential for Offshore Energy Systems

Plate heat exchangers are essential components in offshore energy systems, offering advanced solutions for the unique challenges of marine environments. For example, they help effectively maintain optimal temperatures to prevent hydrate formation and pipeline blockages.

Specialized designs such as the Welded Plate Heat Exchanger and Printed Circuit Heat Exchanger utilize robust materials to resist corrosion and withstand the demanding conditions found offshore. The compact and modular construction of these plate heat exchanger types makes them ideal for platforms where space is at a premium.

Challenges of Offshore Environments

Limited Space and Weight Restrictions

Offshore energy platforms operate under strict space and weight constraints. Every piece of equipment must fit within a compact footprint and contribute minimal weight to the overall structure. These limitations stem from the need to reduce platform construction costs and enable the use of smaller, more economical rigs, especially in deepwater or marginal fields. Key factors include:

· Reducing rig weight directly lowers platform weight, with each pound saved on the rig translating to three to five pounds less on the platform.

· Equipment such as masts and cranes has evolved to become lighter and more compact, fitting within limited deck space and crane capacity.

· Modular components now replace bulkier traditional systems, allowing for easier installation and transport.

· Mud system equipment, including pumps and tanks, is designed to maximize efficiency while occupying less space.

These innovations drive the demand for oil and gas heat exchangers that deliver high performance without adding unnecessary bulk or weight.

Corrosive Marine Conditions

Offshore environments expose equipment to a range of aggressive factors that accelerate corrosion. The following table summarizes how marine conditions contribute to corrosion in offshore systems:

Marine Environmental Factor | Contribution to Corrosion in Offshore Equipment |

Salinity | High salt concentration increases chloride ion penetration, intensifying electrochemical corrosion. |

Temperature | Elevated temperatures speed up corrosion reactions, especially in tropical waters. |

Oxygen and Humidity | Oxygen promotes oxidation, while humidity facilitates electrochemical currents that degrade protective coatings. |

Biofouling | Marine organisms interfere with protection systems and cause microbiological corrosion. |

Pressure and Depth | Greater depths increase pressure, reducing the effectiveness of protective coatings. |

Water Movement | Currents and waves erode protective layers, exposing metals to corrosive elements. |

Atmospheric Exposure | Above-water sections face accelerated corrosion from salty air, humidity, and UV exposure. |

These factors demand the use of advanced materials and protective strategies in all offshore heat exchanger designs.

High Efficiency Demands

Offshore energy systems require fuel oil heat exchangers that meet rigorous efficiency standards. Operators expect heat transfer effectiveness between 80% and 95%, with advanced plate designs reducing fouling and supporting prolonged service intervals. Modern heat exchangers, such as those featuring Smart Eye technologies, optimize flow distribution and thermal fit. These innovations help lower energy consumption, minimize maintenance needs, and ensure compliance with industry codes like ASME, API, and TEMA. By meeting these high efficiency benchmarks, offshore platforms achieve reliable performance and operational cost savings.

Maintenance and Accessibility Issues

Offshore energy platforms face unique maintenance and accessibility challenges. Harsh marine conditions, limited space, and safety regulations make routine servicing difficult. Equipment must operate reliably with minimal intervention, as unplanned downtime can lead to significant financial losses.

Gas Plate heat exchangers offer several advantages in this context:

· Modular Construction: Engineers design plate heat exchangers with modular components. This allows technicians to disassemble, inspect, and clean units quickly. They can replace individual plates without removing the entire system.

· Compact Footprint: The compact design enables easy access in tight spaces. Maintenance crews can reach and service the units without extensive disassembly of surrounding equipment.

· Simplified Cleaning: Plate heat exchangers support straightforward cleaning procedures. Operators can use cleaning-in-place (CIP) systems or manual cleaning methods. This reduces the time and labor required for maintenance.

· Reduced Downtime: Quick access and easy servicing minimize operational interruptions. Offshore platforms benefit from higher equipment availability and improved productivity.

Tip: Regular inspection and cleaning of plate heat exchangers help maintain optimal performance and extend equipment lifespan.

The following table highlights key maintenance features of plate heat exchangers compared to traditional heat exchangers:

Feature | Plate Heat Exchanger | Traditional Heat Exchanger |

Modular Design | ✔️ | ❌ |

Easy Plate Replacement | ✔️ | ❌ |

Cleaning-in-Place (CIP) | ✔️ | ❌ |

Compact Size | ✔️ | ❌ |

Technicians working offshore appreciate the accessibility and user-friendly design of offshore phes. These features ensure that maintenance tasks remain manageable, even in challenging marine environments. As a result, offshore operators experience fewer disruptions and maintain consistent energy production.

Key Advantages of Plate Type Heat Exchangers

Compact and Lightweight Design

Offshore energy platforms demand equipment that fits into tight spaces and adds minimal weight. Plate heat exchangers meet these requirements with their innovative stacking of thin, corrugated plates. This design reduces the overall footprint compared to traditional shell-and-tube exchangers, even when both provide the same heat transfer surface area.

For example, a compact integrated separator and heat exchanger system can weigh significantly less than a traditional shell-and-tube version. In some offshore steam bottoming cycles, engineers have achieved weight reductions of 38% to 52% by optimizing the design and using advanced materials.

Superior Heat Transfer Efficiency

Plate heat exchangers deliver outstanding thermal performance, which is essential for offshore energy systems. The corrugated plates create turbulence as fluids pass through, increasing the heat transfer rate. This design allows for a closer temperature approach between fluids, maximizing energy recovery and minimizing losses.

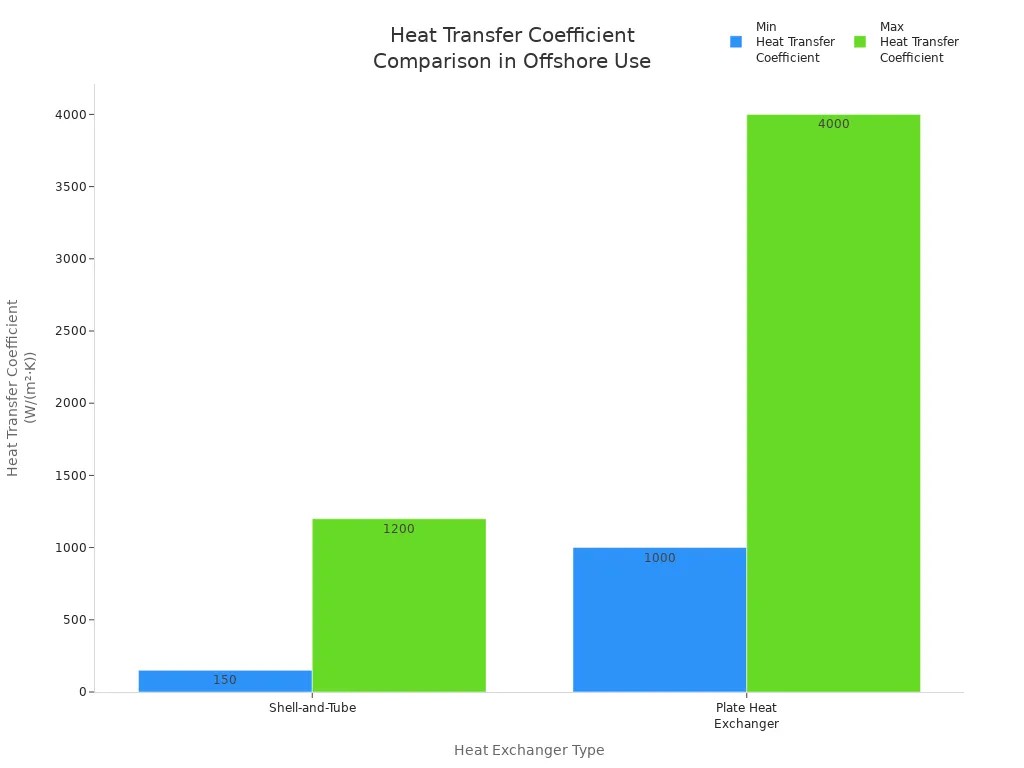

The following table compares the heat transfer coefficients of different heat exchanger types commonly used offshore:

Heat Exchanger Type | Heat Transfer Coefficient Range (W/(m²·K)) | Key Characteristics |

Shell-and-Tube | 150 - 1200 | Larger footprint, lower heat transfer efficiency |

Plate Heat Exchanger | 1000 - 4000 | Higher turbulence due to corrugated plates, compact size, closer temperature approach, up to 5x more efficient |

Plate heat exchangers can achieve heat transfer coefficients up to five times higher than shell-and-tube designs. Research also shows that using advanced working fluids, such as nanofluids, can further boost efficiency by over 36%. These features enable offshore operators to meet strict efficiency targets, reduce energy consumption, and maintain reliable performance in demanding marine environments.

Material Flexibility for Corrosion Resistance

Manufacturers design plate heat exchangers with a wide range of materials to match specific process requirements and environmental threats. The most common choices include:

· Stainless Steel: Grades such as 316L and 254SMO provide excellent resistance to chloride-induced corrosion. Stainless steel suits most seawater and process fluid applications.

· Titanium: Titanium resists aggressive seawater corrosion and biofouling. It remains stable even in high-salinity environments, making it ideal for desalination and marine cooling systems.

· Nickel Alloys: Alloys like Hastelloy and Inconel withstand both chemical attack and high temperatures. These materials serve well in offshore chemical processing and gas treatment.

· Duplex and Super Duplex Stainless Steels: These advanced alloys combine high strength with outstanding corrosion resistance. They perform reliably in deepwater and high-pressure environments.

The following table summarizes the corrosion resistance of common plate materials used offshore:

Material Type | Corrosion Resistance | Typical Offshore Application |

316L Stainless Steel | High | General seawater cooling, oil platforms |

Titanium | Very High | Desalination, marine HVAC, FSRU systems |

Hastelloy/Inconel (Nickel) | Extreme | Chemical processing, gas treatment |

Super Duplex Stainless Steel | Superior | Deepwater, high-pressure oil & gas systems |

Plate Heat Exchanger vs. Other Heat Exchanger Types

Plate Heat Exchanger vs. Shell-and-Tube Heat Exchanger

Offshore energy systems often compare small plate heat exchangers with shell-and-tube designs. The differences in performance and practicality are significant. Plate heat exchangers deliver up to five times higher heat transfer efficiency.

Aspect | Plate Heat Exchanger (PHE) | Shell-and-Tube Heat Exchanger |

Heat Transfer Efficiency | Up to 5x higher (1000-6000 W/m²K) | 150-1200 W/m²K |

Footprint and Weight | Small, lightweight | Large, heavy |

Maintenance | Easy, modular | Labor-intensive |

Capacity Flexibility | Expandable | Fixed |

Cost | Lower overall | Higher |

Plate Heat Exchanger vs. Air-Cooled Heat Exchanger

Air-cooled heat exchangers use ambient air and finned tubes for cooling. These units suit dry environments where water is scarce. However, they require a larger footprint and offer lower heat transfer efficiency compared to plate heat exchangers. SHPHE’ Plate heat exchangers use fluid-to-fluid transfer, which allows for higher efficiency and compactness. Their modular design supports easy cleaning and maintenance. Offshore platforms benefit from the ability to handle high pressures and corrosive fluids, which air-cooled units cannot match.

Summary: Why Plate Heat Exchangers Are Preferred in Offshore Projects

Plate heat exchangers stand out in offshore applications for several reasons:

· Compact design fits limited space on platforms.

· High thermal efficiency supports energy savings.

· Corrosion-resistant materials like stainless steel and titanium ensure durability.

· Modular construction allows for quick inspection and cleaning.

· Welded options prevent leaks in harsh marine conditions.

· They meet strict industry standards for safety and reliability.

Real-World Applications of Plate Heat Exchangers in Offshore Energy

Oil and Gas Production Platforms

Oil and gas production platforms rely on advanced thermal management to ensure safe and efficient operations. Plate heat exchangers provide a compact and efficient solution for these platforms, where space and weight are at a premium. Their design, featuring multiple thin plates, delivers excellent thermal efficiency. Operators use them for engine cooling, oil cooling, and HVAC systems. These exchangers also play a key role in crude oil stabilization, pre-heating crude oil for desalting, and cooling desalted crude oil before storage. They handle produced water with high salinity and support natural gas dehydration, preventing hydrate formation and corrosion. Their compactness, reliability, and ease of maintenance make them ideal for the demanding conditions of offshore environments.

· Common uses on offshore platforms:

o Crude oil stabilization and desalting

o Produced water cooling

o Natural gas dehydration

o Gas sweetening and compression trains

Offshore Natural Gas Processing and FSRU Systems

Offshore natural gas processing and Floating Storage Regasification Units (FSRUs) demand equipment that can withstand high pressures and dynamic conditions. Printed circuit heat exchangers (PCHEs), a type of plate heat exchanger, reduce volume and weight by up to 85% compared to traditional designs. This compactness leads to significant cost savings in construction and maintenance. PCHEs handle pressures up to 1,250 bar and temperatures from -196°C to 800°C, making them suitable for LNG regasification and natural gas cooling. Their robust construction and advanced flow channel design ensure reliable, high-efficiency operation even under sloshing and temperature stresses common offshore.

Note: The modularity and optimized flow channels of PCHEs maintain high efficiency and reliability, supporting safe and continuous operation in harsh marine environments.

Seawater Desalination Processes

Offshore platforms often require freshwater for operations and crew. Plate heat exchangers play a vital role in seawater desalination processes such as Multi-Stage Flash (MSF), Multi-Effect (ME), and Vapor Compression (VC). Their corrosion-resistant construction, often using titanium or stainless steel, ensures durability in harsh seawater conditions. These exchangers enable efficient heat transfer, improve energy efficiency, and reduce maintenance needs. The table below highlights their importance in offshore desalination:

Aspect | Description |

Role in Desalination | Efficient heat transfer in MSF, ME, and VC processes |

Material Requirements | Titanium and stainless steel for corrosion resistance |

Industry Trend | Growing demand for large-scale desalination on offshore platforms |

Importance | Supports sustainable freshwater production and thermal management offshore |

Marine Vessel Engine and HVAC Systems

Marine vessels operate in challenging environments where temperature control is critical. Engineers use plate heat exchangers to manage engine cooling and maintain optimal performance. These systems transfer heat efficiently from engine coolant to seawater, preventing overheating and reducing wear on vital components. The compact design fits easily into tight engine rooms, saving valuable space on board.

In addition to engine cooling, plate heat exchangers support marine HVAC systems. They regulate air conditioning and heating for crew comfort and equipment protection. The modular construction allows for quick maintenance, which is essential during long voyages. Operators benefit from reduced downtime and improved reliability.

Marine Environmental Protection and Chemical Industry

Offshore platforms and vessels must meet strict environmental standards. Plate heat exchangers play a key role in environmental protection systems. They support water treatment units, oil-water separation, and waste heat recovery. These applications help reduce emissions and minimize the environmental impact of marine operations.

In the marine chemical industry, fully welded phe handle corrosive fluids during processes like chlor-alkali production and salt refining. Their corrosion-resistant materials, such as titanium and special stainless steels, ensure safe and efficient operation. Operators experience lower maintenance costs and improved process safety.

Application Area | Benefit Provided by PHEs |

Water Treatment | Stable heat transfer, reliable operation |

Chemical Processing | Corrosion resistance, energy efficiency |

Case Study: Plate Heat Exchangers in Floating Production Storage and Offloading (FPSO) Units

Units.jpg)

FPSO units require robust thermal management to process, store, and offload hydrocarbons safely. Engineers select block heat exchangers for their high efficiency and compact footprint. These units handle crude oil cooling, produced water treatment, and gas processing. The modular design allows for easy scaling and adaptation to changing process needs.

Operators report improved uptime and reduced maintenance with plate heat exchangers on FPSOs. The ability to withstand harsh marine conditions ensures long-term reliability. This technology supports safe, continuous production in some of the world’s most demanding offshore environments.

FAQs

What makes plate heat exchangers suitable for offshore environments?

Plate heat exchangers use corrosion-resistant materials and compact designs. These features help them withstand harsh marine conditions and fit into limited spaces on offshore platforms. Operators value their reliability and efficiency in demanding environments.

How often should technicians clean plate heat exchangers offshore?

Technicians should inspect and clean plate heat exchangers regularly, based on process conditions and fouling rates. Many offshore operators schedule maintenance every three to six months to ensure optimal performance and prevent unexpected downtime.

Which materials work best for plate heat exchangers in seawater applications?

Titanium and high-grade stainless steels, such as 316L or super duplex, offer excellent corrosion resistance. These materials extend equipment life and reduce maintenance needs in seawater cooling, desalination, and marine HVAC systems.

Can plate heat exchangers handle high-pressure offshore processes?

Yes. Plate heat exchangers, especially welded and printed circuit types, withstand high pressures and temperatures. Engineers select these models for LNG regasification, gas compression, and other critical offshore applications.

What are the main benefits of using plate heat exchangers on marine vessels?

Plate heat exchangers save space, reduce weight, and provide efficient heat transfer. They support engine cooling, HVAC, and environmental systems. Their modular design allows for quick maintenance, which helps maintain vessel reliability and crew comfort.

If you need further consultation and discussion, please feel free to contact us.

Email: info@shphe.com

WhatsApp /Cell: +86 15201818405