Why Welded Plate Heat Exchangers Excel in Industrial Use

Unmatched Durability in Demanding Conditions

Industrial processes often involve extreme operating parameters that can compromise equipment integrity. Welded plate heat exchangers are specifically engineered to thrive in these environments, offering a robust and reliable solution where other technologies may fail. Their durability stems from fundamental design advantages in handling pressure, temperature, and aggressive fluids.

Superior Pressure and Temperature Resistance

Traditional gasketed heat exchangers have a significant limitation. Their elastomeric gaskets define the operational boundaries for pressure and temperature. These gaskets degrade, lose elasticity, or fail completely when exposed to conditions beyond their design limits.

A welded plate heat exchanger overcomes this vulnerability by eliminating gaskets from the plate pack. The plates are laser-welded together, creating a solid, metallic bond that can withstand far greater stress.

Key Advantage: The absence of gaskets means the operational limits are determined by the metal's strength, not a polymer's weakness. This allows these units to operate reliably at extreme temperatures up to 1000°C (1832°F) and pressures exceeding 100 bar (1450 psi).

This capability makes them indispensable for high-stakes applications like steam condensation, gas processing, and thermal oil systems, where operational stability is paramount.

Enhanced Material Integrity and Leak Prevention

The integrity of a heat exchanger is critical, especially when handling hazardous, corrosive, or high-purity fluids. Leaks can lead to safety incidents, environmental damage, and costly production downtime. The construction of welded units provides exceptional protection against these risks.

The welds create a permanent, hermetic seal between the plates. This robust design offers several key benefits for industrial operators:

·Prevents Cross-Contamination: The secure seal eliminates any pathway for fluids to mix between channels, ensuring product purity and process safety.

·Handles Aggressive Media: The all-welded construction is ideal for managing corrosive substances like acids, solvents, and ammonia that would quickly degrade conventional gaskets.

·Reduces Maintenance Needs: Operators do not need to plan for gasket replacement, which simplifies maintenance schedules and lowers long-term labor costs.

This enhanced material integrity provides peace of mind, ensuring that the heat exchanger performs reliably and safely throughout its long service life.

Key Advantages of a Welded Plate Heat Exchanger

Beyond their exceptional durability, these exchangers deliver core performance benefits that directly impact operational efficiency and plant design. Their advanced engineering maximizes thermal transfer while minimizing the physical space required, offering a powerful combination for modern industrial facilities.

Maximizing Thermal Performance

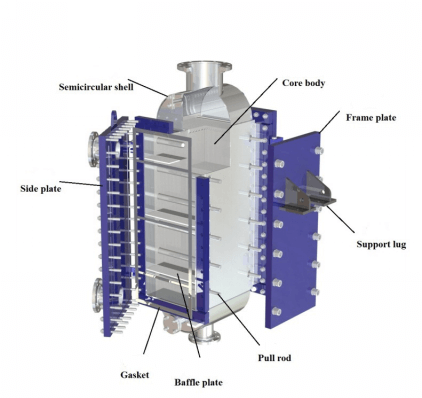

The primary goal of any heat exchanger is to transfer thermal energy effectively. A welded plate heat exchanger achieves this with remarkable efficiency due to its fundamental design. The unit consists of a series of thin, corrugated metal plates. This construction creates a significant advantage.

·High Turbulence: As fluids flow through the narrow channels between the plates, the corrugated pattern creates high turbulence. This turbulent flow prevents stagnant boundary layers from forming and ensures that more of the fluid makes contact with the plate surface, dramatically increasing the heat transfer rate.

·Large Surface Area: The design packs a massive amount of surface area into a very small volume. This high-density surface area allows for more thermal exchange to occur within the unit compared to other exchanger types of a similar size.

In contrast, traditional shell-and-tube exchangers have a much lower heat transfer coefficient. Their design results in less efficient flow patterns and a lower surface-area-to-volume ratio. This means they require a significantly larger footprint to perform the same thermal duty.

Achieving a Compact Footprint

Space is a valuable commodity in any industrial plant, whether it's a new build or a retrofit project. The superior thermal efficiency of a welded plate heat exchanger translates directly into a smaller, lighter unit.

Key Insight: For the same heat transfer duty, a welded unit can be up to 80% smaller and significantly lighter than a comparable shell-and-tube exchanger.

This compact footprint delivers major benefits for plant design and logistics. It allows engineers to fit high-capacity heat transfer solutions into tight spaces, freeing up valuable floor area for other critical equipment. The reduced weight also simplifies transportation, installation, and structural support requirements, leading to lower project costs and faster implementation. This makes them an ideal choice for offshore platforms, modular skids, and crowded mechanical rooms where every square foot matters.

Driving Sustainability and Cost-Effectiveness

Smart equipment choices directly influence a plant's financial and environmental performance. A welded plate heat exchanger delivers significant advantages in both areas. It provides a pathway to lower operational expenses and a smaller carbon footprint.

Lowering Total Cost of Ownership

The initial purchase price is only one part of an asset's financial story. Total Cost of Ownership (TCO) includes maintenance, repairs, and operational expenses over the equipment's entire life. These units excel at reducing long-term costs.

·No Gasket Expenses: Eliminating gaskets removes the recurring cost of purchasing and replacing them.

·Reduced Labor: Maintenance teams spend less time servicing the unit, freeing them for other critical tasks.

·Longer Service Life: The robust, all-welded construction resists fatigue and corrosion, leading to a longer operational lifespan compared to gasketed alternatives.

This combination of factors results in a significantly lower TCO, making it a financially sound investment.

Optimizing Operational Uptime

Unplanned downtime is one of the biggest threats to profitability in any industrial process. The reliability of these heat exchangers is a powerful defense against it. Their leak-proof design prevents failures that could halt production. Since there are no gaskets to fail or replace, operators can avoid the planned downtime required for re-gasketing. This superior reliability ensures the process runs continuously, maximizing output and revenue.

Reducing Energy Consumption

Energy efficiency is a cornerstone of modern sustainability and cost control. The high thermal performance of these units plays a crucial role here.

Key Impact: Their superior heat transfer capability means they achieve the target temperature with less energy. This efficiency directly translates to lower fuel or electricity consumption.

By requiring less energy to perform the same thermal duty, these exchangers help facilities reduce their utility bills and shrink their overall environmental impact. This makes them an essential component for any operation focused on sustainable and cost-effective performance.

Versatility Across Industrial Applications

The robust design of a welded plate heat exchanger makes it a highly adaptable solution for numerous industries. Its ability to handle extreme conditions and challenging fluids allows it to excel where other technologies cannot. This versatility ensures reliable performance across a wide spectrum of demanding heat transfer duties.

Ideal for Aggressive and Challenging Media

Many industrial processes use fluids that can destroy conventional equipment. The all-welded construction of these units provides a superior solution for managing such media. The design eliminates gaskets, which are often the weakest point when exposed to corrosive or hazardous substances. This makes the unit inherently safer and more reliable.

These exchangers confidently handle a range of difficult fluids, including:

·Acids and caustics

·Organic solvents

·Ammonia and other refrigerants

·High-purity process fluids

By removing the risk of gasket degradation, operators can ensure process integrity and prevent dangerous leaks. This is critical for protecting personnel, the environment, and product quality.

Key Application Examples

The combination of durability, efficiency, and a compact design makes these heat exchangers a preferred choice in many sectors. Their performance benefits translate directly to improved operations in various critical systems. The table below highlights some key examples.

| Industry | Typical Application |

|---|---|

| Oil & Gas | Crude Oil Cooling, Gas Dehydration, Glycol Reboilers |

| Chemical Processing | Acid Interchangers, Solvent Condensing, Polymer Coolers |

| Power Generation | Turbine Lube Oil Cooling, Closed-Loop Cooling Water |

| HVAC & Refrigeration | Ammonia Condensers, District Energy Substations |

This wide applicability demonstrates their status as a go-to technology for solving complex thermal challenges.

A welded plate heat exchanger delivers superior durability, efficiency, and a lower total cost of ownership. Its robust, compact design establishes it as the optimal solution for challenging industrial tasks. For demanding applications that require unmatched reliability and performance, the welded plate heat exchanger is the clear and superior choice.

FAQ

How are welded plate heat exchangers cleaned?

They are cleaned using Cleaning-In-Place (CIP). Chemical solutions circulate through the unit to dissolve fouling. This method avoids disassembly and restores performance efficiently and safely.

Can a welded plate heat exchanger be repaired if it leaks?

Yes, repairs are possible. Technicians can often seal a leaking channel, isolating the problem area. The unit can then return to service with a slightly reduced capacity.

What is the typical service life of these units?

Their robust, all-welded construction provides a long operational lifespan. With proper maintenance, these units can reliably perform for 20 years or more in demanding industrial service.