Understanding Printed Circuit Heat Exchangers (PCHEs)

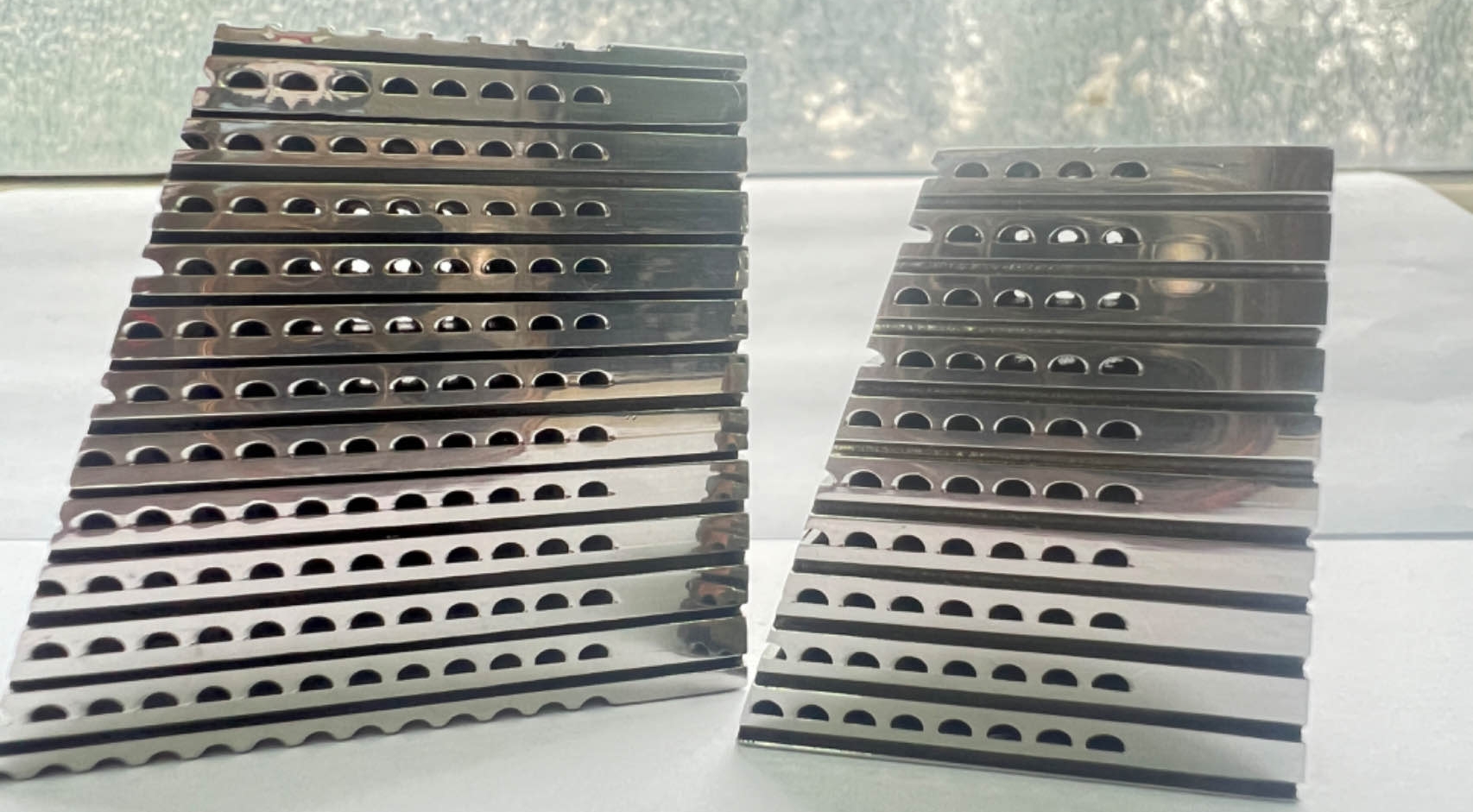

Printed Circuit Heat Exchangers (PCHEs) are ultra-compact, diffusion-welded plate heat exchangers designed for extreme operating conditions. Unlike conventional shell-and-tube or brazed-plate exchangers, a PCHE consists of thin metal plates with microchannels etched into their surfaces.

These plates are chemically etched (similar to printed circuit boards), then stacked and diffusion-bonded to form a monolithic block. This construction yields an exceptionally large surface-area-to-volume ratio: the etched microchannels maximize heat transfer area while minimizing size.

PCHEs routinely operate at temperatures up to 850 °C and pressures up to 1,000 bar – far beyond the limits of traditional designs. The result is a rugged, leak-proof exchanger ideal for aggressive fluids and vibration-prone environments. In short, a PCHE is a groundbreaking compact heat exchanger for high-pressure, high-temperature duties.

Advantages of Printed Circuit Heat Exchangers

Printed Circuit Heat Exchanger's design offers several key advantages over conventional exchangers, making them attractive for modern industry:

Exceptional Thermal Efficiency:

Thanks to their dense microchannel geometry, PCHEs can achieve thermal effectiveness as high as 95–98%. The intricate flow paths promote nearly complete heat exchange between fluids, far surpassing the performance of shell-and-tube units. High effectiveness translates to lower approach temperatures and reduced energy losses.

Compact Size and High Heat Flux:

By etching many small channels into each plate, PCHEs pack a huge heat transfer surface into a small volume. This yields an ultra-compact design with minimal footprint. For example, photo-etched microchannels create a “solid core packed with heat transfer area,” giving maximum efficiency in a minimal space. Engineers routinely cite space savings on the order of 80–90% compared to equivalent shell-and-tube exchangers.

High Pressure and Temperature Capability:

PCHEs are built to handle extreme conditions. Industry leaders report operating ranges up to 1,000 bar and –196°C to 850°C (and even higher). The diffusion-bonded core has no mechanical joints or gaskets in the flow channels, so it can withstand pressures beyond 1,000 bar. This robustness makes PCHEs suitable for supercritical fluids, compressed gases, and cryogenic applications alike.

Mechanical Durability and Reliability:

The all-welded core eliminates common failure points. There are no gaskets or braze joints in the active flow areas, so PCHEs are immune to leakage and fatigue caused by flow pulsations or vibrations. Additionally, diffusion bonding preserves the full strength and corrosion resistance of the base metal (often stainless steel or nickel alloys), yielding outstanding durability. In corrosive or high-vibration settings – from petrochemical reactors to rocket engines – PCHEs provide leak-proof service where other exchangers might fail.

Customizable Flow Geometry:

One of PCHEs’ unique strengths is design flexibility. Because the channels are etched using photolithography, manufacturers can implement complex, counter-flow or cross-flow patterns tuned to each application. This design freedom enables optimization of heat transfer versus pressure drop for any pair of fluids. In practice, engineers often design PCHE plates with tailored corrugation profiles and channel layouts to balance heat transfer, pressure drop, and flow distribution.

These benefits translate into real-world savings. For example, field studies show that PCHEs can cut pump work and energy use by up to 30% compared to shell-and-tube units, thanks to the high heat recovery. Their compactness also reduces material costs and installation footprint. In short, PCHEs deliver industry-leading thermal performance, minimal pressure drop, and life-cycle cost savings.

Applications of PCHEs Across Industries

Because of their robustness and efficiency, PCHEs find wide adoption in demanding sectors:

Oil & Gas and LNG:

PCHEs are extensively used in upstream and LNG processes. In LNG liquefaction/regasification, they handle cryogenic temperatures and high pressures for gas precooling and subcooling. On Floating Storage Regasification Units (FSRUs) and LNG carriers, PCHEs serve as fuel-gas vaporizer units and BOG (boil-off gas) recovery exchangers. They also heat and cool hydrocarbon streams in offshore gas-compression plants, enhancing gas-oil separation and dew-pointing.

Power Generation and Renewable Energy:

In power and renewable systems, PCHEs excel in heat-recovery and high-temperature cycles. They are used in supercritical CO₂ (sCO₂) power cycles for concentrated solar power, boosting efficiency in closed-loop cycles. In turbine power plants, PCHEs preheat fuel gas before combustion and manage waste-heat recovery. Nuclear plants (including advanced reactor designs) also adopt PCHEs for reactor-coolant and auxiliary heat-exchange duties.

Chemical and Petrochemical Processing:

Chemical plants use PCHEs wherever space is tight or harsh conditions prevail. Examples include high-pressure reactors (e.g. hydrogenation), specialty gas pipelines, and reflux condensers in petrochemical crackers. The corrosion-resistant alloys often used (Inconel, Hastelloy) allow PCHEs to contact aggressive fluids (acids, ammonia, chlorine) that would quickly degrade conventional exchangers.

Marine and Offshore:

Beyond LNG carriers, PCHEs appear in marine propulsion and utility systems. On gas-fueled ships, they compactly recover waste heat and preheat fuel. In offshore platforms and FPSOs, PCHEs are used for heat recovery from compressors and pumps, or for conditioning feedwater in limited spaces.

Aerospace and Defense:

High pressure and temperature management is critical in aerospace. PCHEs are used in rocket engine cooling (fuel-side recuperators) and on spacecraft for life-support heat rejection loops. Their ability to handle very high pressures and cryogenic fluids (like liquid oxygen or hydrogen) in a compact structure is unmatched.

Chemical Etching in PCHE Manufacturing vs Traditional Fabrication

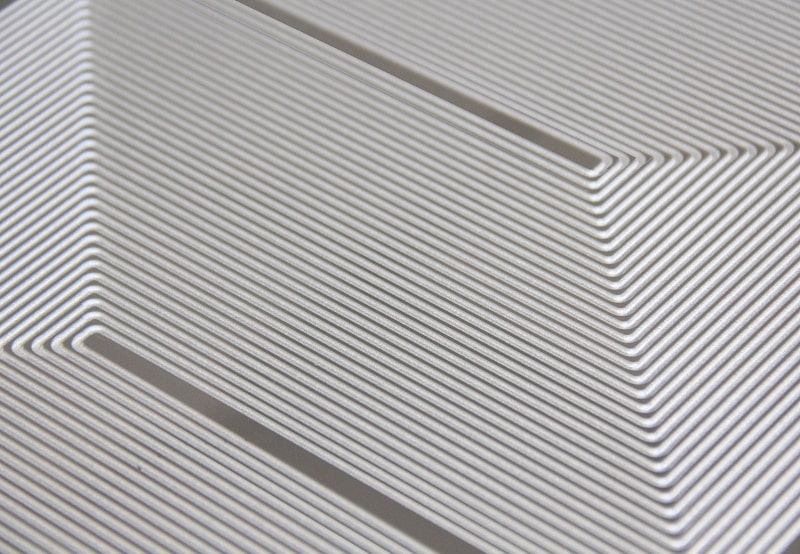

A key to PCHE performance is the chemical etching process used to make its plates. Similar to printed-circuit boards, the microchannels are created by a photochemical etch: a photoresist mask is applied to a metal plate (stainless steel, titanium, etc.), then the uncovered areas are dissolved by acid etchants. This etching step imparts the precise channel geometry required for high-efficiency heat transfer.

Chemical etching offers several manufacturing advantages over traditional methods:

Complex Channel Geometries:

Unlike mechanical punching or stamping, photochemical etching is non-contact and uses no moving tools, so it can produce very fine, intricate channel patterns without burring or tool wear. This provides full design freedom in channel layout, maximizing surface area. In contrast, conventional plate exchangers are usually limited to simple wavy or pressed patterns because stamping deeper or more complex shapes would distort the plate.

Stress-Free Plates:

Mechanical methods (stamping, punching, or even laser cutting) introduce residual stresses and deformation in the metal. By contrast, chemical etching leaves the plate flat and stress-free. Photo etching leaves no mechanical or thermal stress, unlike CNC machining, stamping and laser machining, which can compromise flatness. Maintaining planarity is crucial for the subsequent diffusion-bonding step, ensuring uniform contact across the plate stack.

High Precision and Reproducibility:

The etching process is governed by well-controlled chemical kinetics and photomasks, so it can reproducibly hit very tight tolerances on channel dimensions (widths often just a few millimeters or less). It also allows very thin web sections between channels for higher heat flux. Traditional milling or drilling would struggle to achieve the same resolution at scale.

After etching, the plates are stacked and diffusion bonded (also called diffusion welding). In diffusion bonding, the stack of etched plates is pressed at high temperature and pressure so that the metal surfaces fuse atomically. This creates a solid, monolithic core with no discrete weld seams in the channels. The bonded block is then machined or cut to size and fitted with headers (end-caps) and nozzles. This manufacturing sequence contrasts with conventional exchangers, where plates might be gasketed or brazed. Because PCHEs use diffusion bonding, the bonded joints retain the full parent metal properties (strength, corrosion resistance), avoiding the weakness of filler metals or gaskets.

SHPHE’s High-Performance PCHE Solutions

Printed circuit heat exchangers are a mature yet still-evolving technology, pushing the limits of compact heat transfer. They have become essential wherever high pressures, high temperatures, or tight space constraints exist. SHPHE highlights on its product page, the PCHE is a groundbreaking innovation in heat exchange technology, tailored for demanding industrial applications. Its high-efficiency, compact design – capable of operating up to 1,000 bar and 900°C – makes it ideal for LNG, nuclear, supercritical CO₂, and aerospace systems.

SHPHE’s published specifications underscore the company’s competitive edge: our PCHE units carry ASME and international certifications, and are rated for pressures up to 1000 bar and temperatures from –196°C to 850°C. This reflects SHPHE’s mastery of advanced etching and diffusion-bonding processes, enabling us to fabricate plates 0.4–4 mm thick with channels as small as 0.4 mm. In practice, such capabilities allow SHPHE to supply exchangers that meet the strictest standards of the petrochemical, power, and process industries.

PCHE technology represents the state of the art in compact heat exchangers. By combining photochemical etching, diffusion bonding, and smart hydraulic design, SHPHE delivers solutions with unmatched efficiency, robustness, and flexibility.

If you need further consultation and discussion, please feel free to contact us.

Email: info@shphe.com

WhatsApp / Cell: +86 15201818405