How To Choose/Select a Plate Heat Exchanger

Understanding Plate Heat Exchangers

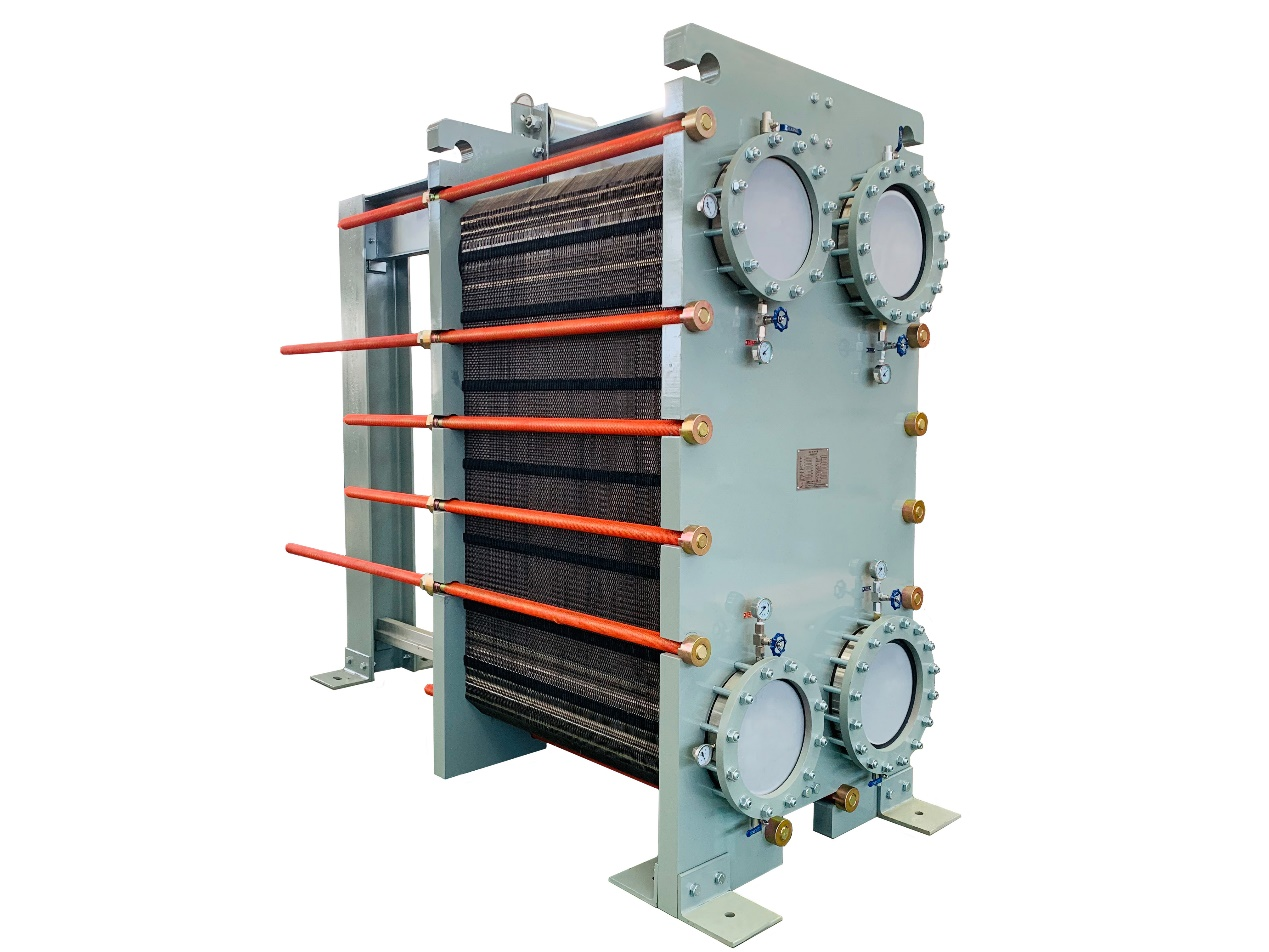

Plate Heat Exchangers (PHEs) are pivotal components in thermal management systems, facilitating efficient heat transfer between two fluids without direct contact. Comprising a series of thin, corrugated metal plates, these exchangers create alternating channels for hot and cold fluids, maximizing the surface area for heat exchange. This design not only enhances thermal efficiency but also allows for a compact footprint, making PHEs ideal for applications where space is at a premium.

Types of Plate Heat Exchangers and Their Applications

Industrial Plate Heat Exchangers are categorized based on their construction and assembly methods, each tailored to specific operational needs:

Gasketed Plate Heat Exchangers:These feature plates sealed with elastomeric gaskets, allowing for easy disassembly for cleaning and maintenance. Commonly employed in industries like food processing and HVAC systems, they offer flexibility in capacity adjustments.

Welded Plate Heat Exchangers: In these units, plates are welded together, providing a hermetically sealed system suitable for handling aggressive fluids and high-temperature applications, such as chemical processing and power plants.

Printed Circuit Heat Exchanger: A printed circuit heat exchanger (PCHE) is a compact, high-efficiency device designed for transferring heat between fluids under extreme conditions. Constructed by chemically etching intricate microchannels onto metal plates—typically stainless steel or other corrosion-resistant alloys—and subsequently diffusion bonding them into a solid block, PCHEs achieve exceptional thermal performance within a minimal footprint.

Each type serves distinct applications, with selection contingent upon factors like fluid type, operating conditions, and maintenance considerations.

How Plate Heat Exchanger Works

The operational principle of PHEs hinges on the creation of multiple thin channels through which hot and cold fluids flow alternately. As these fluids traverse the exchanger, heat is transferred through the metal plates from the hotter to the cooler fluid. The corrugated pattern of the plates induces turbulence, enhancing heat transfer efficiency and reducing the likelihood of fouling. This design ensures a high heat transfer coefficient while maintaining a compact and lightweight structure.

Assessing Your Operational Requirements

Selecting an appropriate Plate Heat Exchanger necessitates a thorough evaluation of your system's operational parameters:

- Temperature, Pressure, and Flow

Understanding the maximum and minimum temperatures, pressure ratings, and flow rates of your system is crucial. These parameters dictate the design specifications and material selection for the PHE to ensure safe and efficient operation.

- Matching Application Needs and Process Specifics

Consider the nature of the fluids involved, including their viscosity, corrosiveness, and particulate content. Additionally, assess the desired thermal performance and any industry-specific standards or regulations that must be adhered to.

Selecting Materials and Designs

The choice of materials and design configurations significantly impacts the performance and longevity of a plate heat exchanger:

Plate Configurations and Construction Options

The geometry of the plates, including the angle and depth of the corrugations, affects the heat transfer rate and pressure drop. Selecting an appropriate configuration balances thermal efficiency with acceptable pressure losses.

Material Selection

Stainless Steel PHE , Titanium plate heat exchanger, and Other Alloys

Material compatibility with the fluids is paramount to prevent corrosion and ensure durability. Stainless steel is widely used for its strength and corrosion resistance, while titanium is preferred for highly corrosive environments due to its superior resistance.

Gasketed vs. Welded vs. Printed circuit heat exchanger

The decision between gasketed and welded constructions depends on factors such as maintenance accessibility, operating pressure and temperature, and fluid compatibility.

Gasketed Plate heat exchangers:

They are widely used across industries due to their efficiency, compact design, and versatility. They play a critical role in applications such as HVAC systems, chemical processing, food and beverage production, and power generation. By reducing energy consumption and operational costs, plate heat exchangers significantly enhance industrial efficiency and sustainability, making them indispensable in modern industrial operations.

Gasketed PHE is commonly used in lower operating pressure and temperature such as:

Welded Plate Heat Exchanger:

As a transformative innovation in industrial thermal solutions, HT-Bloc Welded Plate Heat Exchanger redefine system optimization through their patented modular architecture and multi-process adaptability. This in-depth technical analysis examines the engineering principles behind their compact plate-and-shell configuration. Current industrial implementations span various industries due to their efficiency and versatility.

Welded PHE is widely used in higher operating pressure and temperature such as:

Printed circuit heat exchanger:

Printed Circuit Heat Exchangers (PCHEs) are widely used in the natural gas processing industry, particularly in processes requiring efficient heat transfer, compact design, and resistance to high pressure and temperature. Their high thermal efficiency, space-saving structure, and ability to withstand extreme conditions make them a critical component in this sector.

Printed circuit heat exchanger is used in industries with high demand for space such as:

- Offshore oil ang gas industry

- LNG industry

Pressure Drop and Flow Distribution

Efficient operation of a Plate Type Heat Exchanger is influenced by pressure drop and flow distribution:

Pressure drop refers to the reduction in pressure as fluid flows through the exchanger. While a certain pressure drop is necessary to achieve effective heat transfer, excessive pressure losses can lead to increased energy consumption and reduced system performance.

Uniform flow distribution across all channels ensures consistent thermal performance and minimizes the risk of fouling. Maldistribution can cause some channels to carry more flow than others, leading to inefficiencies and potential damage.

Installation, Maintenance, and Expert Tips for Long-Term Success

Proper installation is the cornerstone of any system’s longevity. Whether setting up industrial machinery, HVAC systems, or smart home technology, adhering to manufacturer guidelines and using certified professionals ensures optimal performance and safety. Incorrect installation can lead to inefficiencies, frequent breakdowns, or even hazards.

Regular maintenance is equally critical. Scheduled inspections, cleaning, lubrication, and software updates prevent wear and tear, reduce energy consumption, and extend equipment lifespan. Proactive maintenance minimizes unexpected downtime and costly repairs, safeguarding productivity.

For long-term success, experts recommend:

Documentation: Keep detailed records of installations, repairs, and maintenance activities.

Training: Ensure staff understand operational protocols and troubleshooting basics.

Preventive measures: Use quality parts, monitor performance metrics, and address minor issues before they escalate.

Technology integration: Leverage IoT sensors or predictive analytics for real-time monitoring.

By prioritizing precision in installation, consistency in maintenance, and adopting expert strategies, businesses and homeowners can achieve reliability, cost-efficiency, and sustained performance for years to come.

How to Select a Reputable Manufacturer or Supplier?

Partnering with a manufacturer or supplier known for quality and reliability ensures access to well-engineered products and comprehensive support services.

With advanced engineering and manufacturing technology, comprehensive heat exchanger expertise and rich service experiences, SHPHE dedicates to supply quality plate heat exchangers to various clients worldwide in oil and gas, chemical, power plant, bio-energy, metallurgy, marine, HVAC, mechanical manufacturing, paper & pulp, steel, etc.

SHPHE remains committed to driving industry progress through continuous technological innovation. By partnering with leading companies at home and abroad, SHPHE aims to become a top-tier provider of high-quality solutions in the heat exchange industry, both in China and internationally.

When to Replace or Upgrade Your Heat Exchanger System

Regular performance assessments can identify signs of degradation or inefficiency. Upgrading or replacing the heat exchanger may be warranted when maintenance costs escalate or when technological advancements offer significant improvements in performance.

Shanghai Heat Transfer Equipment Co., Ltd. specializes in the design, manufacturing, installation, and service of plate heat exchangers and complete heat transfer systems.

If you need further consultation and discussion, please feel free to contact us.