Why Choose HT-BLOC Fully Welded Plate Heat Exchanger?

Modern industrial operations constantly demand enhanced efficiency, reliability, and safety, especially when managing thermal processes under extreme conditions. Processes across sectors from chemical manufacturing to power generation operate under increasingly demanding conditions, pushing the boundaries of temperature, pressure, and fluid compatibility. The HT-Bloc Fully Welded Plate Heat Exchanger is one such solution that stands out, delivering outstanding operational integrity even in the harshest environments.

What Makes HT-Bloc Fully Welded PHE Different?

Traditional plate heat exchangers (PHEs) use gaskets to seal between plates. While these designs are effective in standard conditions, they inherently limit performance at elevated pressures or temperatures and can degrade in chemically harsh environments. By contrast, the HT-Bloc unit uses fully welded plate construction, employing laser or plasma welding to bond metal plates without any gaskets within the heat transfer pack.

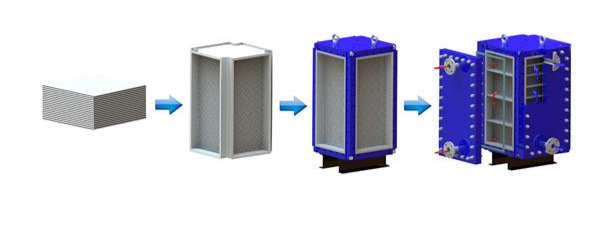

How to assemble Fully Welded Plate Heat Exchanger?

The plate pack is formed by welding a certain number of plates, then it is installed into a frame, which is configured by four corner girders, top and bottom plates and four side covers. HT-Bloc Welded Plate Heat Exchanger utilizes interchangeable components and standardized modules, allowing for easy customization and scalability. This modularity ensures that HT-Bloc heat exchangers can be tailored to meet specific industrial requirements, enhancing both performance and reliability.

Welded block heat exchanger (HT-Bloc) VS Gasketed PHE

Feature | Gasketed PHE | HT-Bloc Fully Welded PHE |

Max Design Pressure | 2.5 Mpa | 4.0Mpa |

Max Temperature | 180 ℃ | Up to 400°C (752°F) |

Compatibility w/ Aggressive Fluids | Limited | Excellent (including acids, solvents) |

Leakage Risk | Moderate (gasket fatigue) | Minimal (welded seals) |

Maintenance Needs | Frequent re-gasketing | Periodic CIP |

Thermal Transfer Efficiency

Beyond its structural advantages, the fully welded phe excels in thermal performance. Its plate design maximizes surface contact between fluids and metal, and the alternating channels encourage turbulent flow—even at relatively low velocities.

Most fully welded designs employ a counter-current flow arrangement, where the hot and cold fluids flow in opposite directions through their respective adjacent channels. This configuration is thermodynamically optimal, maximizing the mean temperature difference (LMTD) along the entire length of the heat exchanger and enabling very close temperature approaches – meaning the outlet temperature of the heated fluid can get very close to the inlet temperature of the heating fluid, signifying high thermal efficacy.

This allows the fully welded plate heat exchanger to achieve remarkably high heat transfer coefficients, often significantly surpassing those of traditional shell-and-tube exchangers for a given duty and footprint. This capacity for process intensification allows for smaller, lighter equipment, saving valuable plant space and potentially reducing structural support requirements.

Common Applications of fully welded plate heat exchanger

The HT-Bloc is engineered to handle highly challenging fluids and environments. Its reliability and leak-free performance make it suitable across diverse industries:

Offshore processing where space is constrained

High-pressure gas and condensate cooling

Corrosive and sour gas containment

Handling acids (e.g., H₂SO₄, HCl), solvents, and caustics

Minimizing cross-contamination and gasket compatibility concerns

Auxiliary steam and condensate recovery systems

Industrial Refrigeration:

Ammonia or CO₂ systems operating under high pressure

Safety-critical applications with hazardous refrigerants

Compact seawater-cooled systems

High corrosion resistance with titanium plate options

Frequently Asked Questions.

Q1: Can HT-Bloc fully welded Plate Heat Exchanger be used with flammable or toxic fluids?

A: Absolutely. The fully welded design provides exceptional containment for hazardous fluids.

Q2: Is fully welded Plate Heat Exchanger suitable for retrofitting existing systems?

A: Yes, thanks to its compact design and customizable connection options.

Q3: What are the cleaning intervals?

A: This depends on your process. Installations with clean fluids may go months or even years without cleaning.

Maintenance of fully plate heat exchanger

Though HT-Bloc units eliminate gasket-related maintenance, they still require routine care to preserve heat transfer performance. The most effective method is Cleaning-In-Place (CIP), which offers:

Non-invasive cleaning without disassembly,

Customized chemical formulations based on fouling type,

Shorter downtime compared to mechanical cleaning.

For particularly heavy fouling, some block-type heat transfer designs feature openable panels for limited mechanical access, enabling high-pressure jet cleaning where needed.

Tips: Monitor pressure drop and temperature differential regularly to detect fouling early and plan proactive cleaning cycles.

Lifecycle Cost Analysis between Gasketed PHE and Fully Welded PHE

While fully welded exchangers command a higher initial capital investment, their lifecycle advantages often result in a lower Total Cost of Ownership.

Gasketed PHEs: Lower initial capital but higher O&M due to gasket procurement and shutdown points for maintenance. Periodic reconditioning can mitigate costs, but frequent gasket changeouts in harsh services can elevate life cycle expenses

Fully Welded PHEs: Higher upfront cost and capital intensity at replacement, but minimal maintenance reduces operational expenses. In applications where leakage or gasket failures are critical risks, the total cost of ownership can be lower despite replacement needs

| Aspect | Gasketed PHE | Fully Welded PHE |

Maintenance | Periodic gasket replacement, CIP, frame reconditioning | Visual/pressure inspections only |

Serviceability | High (plates removable) | None (sealed pack) |

Typical Lifespan | 20 years with reconditioning | 10 years design; 20–40 years achievable with proper care |

Capital vs O&M | Lower capex, higher O&M | Higher capex, lower O&M |

Pressure/Temp Rating | Moderate (gasket limits) | High (up to ~40 barg, 400 ℃) |

The HT-Bloc's exceptional reliability works especially well in continuous operations.

Conclusion:

The HT-Bloc Fully Welded Plate Heat Exchanger is not just a component—it is a strategic asset for industrial processes that demand reliability, safety, and efficiency under the harshest thermal conditions.

lf your process demands exceptional thermal control under challenging conditions, leveraging the advantages of welded plate heat exchanger technology is key to enhancing efficiency and reliability. We invite you to explore the detailed specifications of our HT-Bloc Welded Plate Heat Exchanger and TP Welded Plate Heat Exchanger and Wide Gap Welded Plate Heat Exchanger, or contact our thermal engineering experts today for a consultation on how these solutions can optimize your specific operations.

Email: info@shphe.com

WhatsApp / Cell: +86 15201818405