Working Principle of Printed Circuit Heat Exchangers (PCHE)

Printed Circuit Heat Exchangers (PCHEs) are ultra‐compact, diffusion-bonded plate heat exchangers designed for extreme conditions. Unlike conventional shell-and-tube units, a PCHE is built by chemically etching intricate microchannel patterns onto thin metal plates and then stacking and diffusion-bonding them into a solid, monolithic block.

Working Principle of Printed Circuit Heat Exchangers(PCHE):

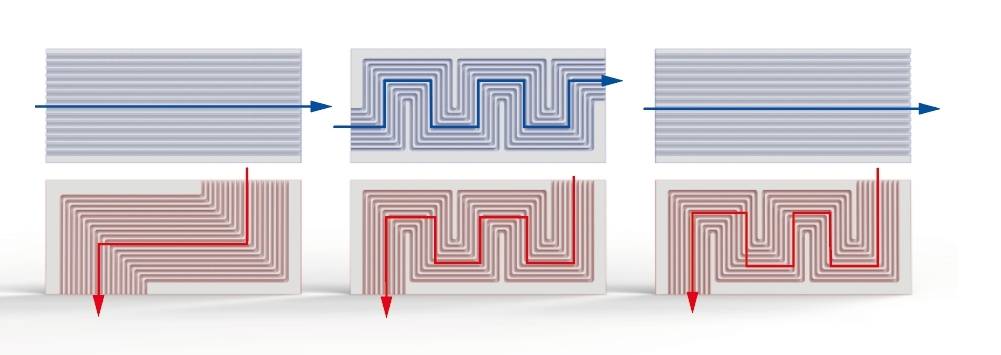

PCHE transfers thermal energy from a hot stream to a cold stream through diffusion-welded metal plates. Each plate has etched channels on both faces, and fluids pass through these channels on opposite sides of the plate. As the hot fluid flows through its channels, heat conducts through the plate wall to the adjacent cold fluid channels, raising (or lowering) the fluid temperatures. Engineers typically arrange the flow paths so that one fluid flows counter-current to the other, maximizing the temperature gradient along the flow and boosting efficiency. Crucially, the etched channels often include small corrugations or bends that induce turbulence even at moderate flow rates, which dramatically increases the convective heat transfer coefficients (often 3,000–7,000 W/m²·K).

For example, a typical PCHE channel pattern forces hot (red) and cold (blue) fluids through winding microchannel paths on each plate. This complex, chemically-etched geometry mixes the flow and maintains a high temperature difference throughout the exchanger.

Because the plate channels can be custom-designed (2D or 3D patterns) for each application, engineers can optimize the thermal length and pressure drop to the process needs. In effect, the working principle of a PCHE is to maximize surface contact between the fluids via tiny etched channels and then to let solid conduction through the thin plate finish the job.

Construction and Design of PCHE

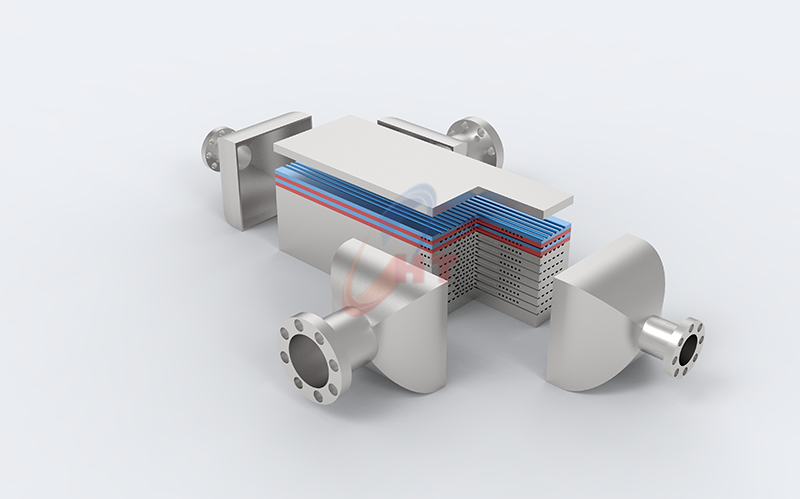

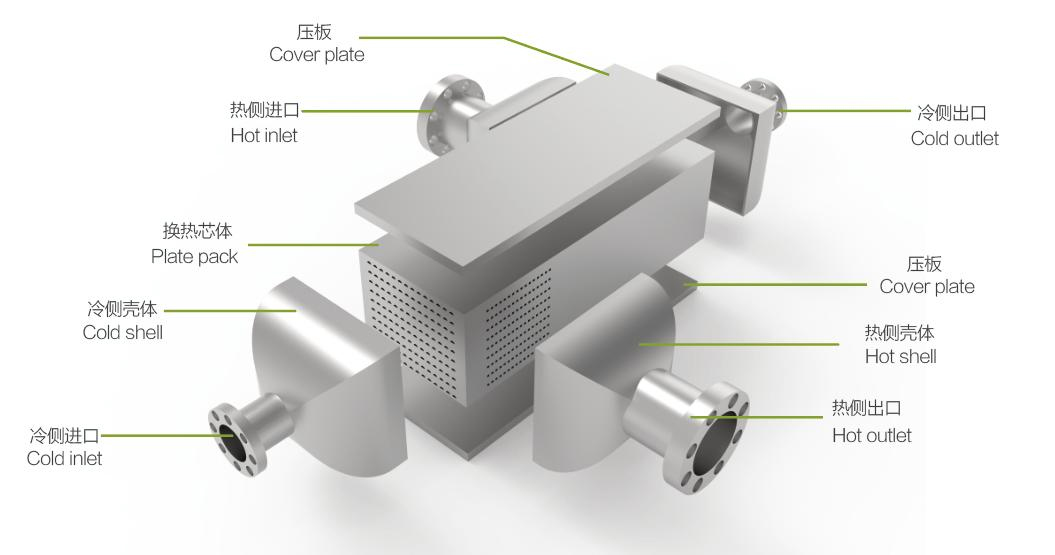

PCHE heat exchangers are constructed from thin metal plates (commonly stainless steel or high-nickel alloys) to withstand harsh conditions. Each plate undergoes precise photochemical etching to create its microchannels. Once etched, the plates are stacked in alternating hot/cold configuration and placed in a high-pressure, high-temperature diffusion-bonding furnace. Under these conditions (typically 70–95% of the metal’s melting point), the metal surfaces weld together at an atomic level, creating a solid, weld-free block. The figure below shows a schematic of the internal PCHE structure after assembly:

The plate pack (dotted block inside) forms the core of the PCHE, sandwiched between a hot-side shell and a cold-side shell. Inlet and outlet manifolds are welded to this block to feed the fluids into their respective channel circuits. Because the entire core is diffusion bonded, there are no gaskets or braze joints in the active passages. This all-welded construction explains the PCHE’s extraordinary pressure tolerance. Diffusion-bonded PCHE cores routinely survive pressures exceeding 1,000 bar and wide temperature swings.

By tailoring the etch pattern on each plate, manufacturers can create asymmetric flow arrangements, multi-pass cycles, or even two-phase flow sections. For instance, one plate might route the hot gas through a zigzag path while the mating plate lets a liquid flow straight through, depending on the process needs. This flexibility lets designers fine-tune heat exchange versus pressure drop.

Performance Highlights

PCHEs offer several key advantages due to their design.

· Exceptional thermal efficiency:

The dense microchannel network allows PCHEs to reach effectiveness of 95–98%. Nearly all the heat is transferred between fluids, far surpassing typical shell-and-tube units. This high efficiency means a very small temperature approach, cutting energy losses.

· Ultra-compact size:

By etching many tiny channels into each plate, PCHEs pack huge heat-transfer surface area into a tiny volume. In fact, PCHEs can occupy 80–90% less space than a comparable shell-and-tube exchanger. This “solid core packed with heat transfer area” makes them ideal where space and weight are at a premium.

· Extreme pressure/temperature capability:

The diffusion-bonded core has no flow gaskets or joints, so it can endure brutal conditions. PCHEs routinely handle cryogenic fluids (down to –196 °C) and supercritical flows (up to 850 °C). Pressures beyond 1,000 bar are achievable, enabling PCHEs to serve in hydrogen fuel systems, advanced reactors, and high-pressure compressors.

· Mechanical durability:

Eliminating gaskets and braze joints means essentially no leak paths in the core. This all-welded design resists fatigue from vibration and thermal cycling. Diffusion bonding preserves full metal strength and corrosion resistance, so PCHEs reliably handle aggressive fluids (acids, ammonia, etc.) where other exchangers fail.

· Design flexibility:

Advanced etching means channels can follow complex patterns. PCHEs can be built with counter-flow, cross-flow or multiple passes to balance heat transfer and pressure drop. Tailored corrugation profiles further boost mixing. Every printed circuit heat exchanger is custom-engineered for its duty, yielding superior performance for each fluid pair.

To illustrate the scale of a PCHE, consider our product specifications from Shanghai Heat Transfer. We offer PCHE cores with:

Parameter | Typical Value |

Maximum Heat Transfer Area | 8000 m² |

Channel Gap (depth) | 0.4–4 mm |

Design Temperature Range | –196 °C to +850 °C |

Maximum Design Pressure | 1000 bar |

Plate Materials | SS304, SS316L, Duplex 2205, Ti, C-276 |

These values reflect the extraordinary thermal capacity and ruggedness of a PCHE.

Applications of Our Printed Circuit Heat Exchanger

The PCHE working principle makes it suitable for the most demanding heat transfer tasks. Typical applications include:

· Liquefied Natural Gas (LNG) processing: PCHEs handle cryogenic temperatures and high pressures during LNG liquefaction and regasification. They are used for fuel-gas vaporization on FSRUs and boil-off gas recovery on carriers.

· Nuclear & power generation: In advanced reactors and supercritical CO₂ cycles, PCHEs serve as compact steam generators or waste-heat recuperators. Their ability to sustain 850 °C and 1000 bar makes them ideal for reactor coolant or high-temperature heat recovery.

· Chemical and petrochemical: Space is tight in refining and chemical plants. PCHEs efficiently exchange heat in high-pressure reactors (e.g. hydrogenation) and dew-point control, while corrosion-resistant alloys let them contact harsh chemicals.

· Hydrogen fueling & carbon capture: PCHEs pre-cool hydrogen before fueling (critical for fast-fill stations) and recover heat in CCS systems. Their precision and efficiency help improve system performance while saving energy.

Overall, the working principle – etched microchannels, diffusion bonding, and counter-current flow – gives PCHEs a unique combination of efficiency, compactness, and strength. These qualities enable them to improve heat recovery and lower energy use. SHPHE's newest studies show that PCHEs can reduce pumping power by ~30% compared to traditional designs, thanks to their high effectiveness.

Shanghai Heat Transfer Equipment Co., Ltd. specializes in the design, manufacturing, installation, and service of plate heat exchangers and complete heat transfer systems.

If you need further consultation and discussion, please feel free to contact us.

Email: info@shphe.com

WhatsApp /Cell: +86 15201818405