Products

HT-Bloc Welded Plate Heat Exchanger

Certificates: ASME, NB, CE, BV, SGS etc.

Our welded plate heat exchangers offer compact, efficient, and trustworthy heat transfer solutions that are custom-tailored to meet an extensive variety of process demands. It comes as no surprise that they have solidified their position as the top-tier option for the most challenging heat exchange scenarios.

In search of expert advice? Our experienced engineers stand ready to assist you. Discover more about our heat exchangers and compl-ementary services, all designed to precisely align with your needs.

contact us

Product details

-

What is HT Bloc welded heat exchanger?

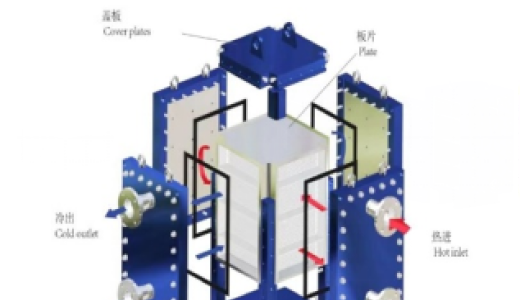

HT-Bloc Welded Plate Heat Exchanger is a type of plate heat exchanger designed for efficient thermal transfer between two fluids. Unlike traditional heat exchangers, HT-Bloc welded heat exchanger is made up of plate pack and frame. HT-Bloc Welded Plate Heat Exchanger combines the high heat transfer efficiency of plate heat exchangers and the high pressure and temperature resistance of shell and tube heat exchangers. -

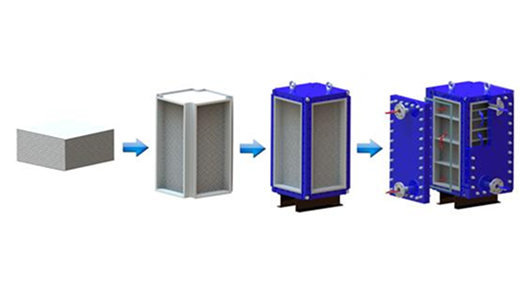

How to assemble HT-Bloc Welded Plate Heat Exchanger?

The plate pack is formed by welding a certain number of plates, then it is installed into a frame, which is configured by four corner girders, top and bottom plates and four side covers. HT-Bloc Welded Plate Heat Exchanger utilizes interchangeable components and standardized modules, allowing for easy customization and scalability. This modularity ensures that Compabloc heat exchangers can be tailored to meet specific industrial requirements, enhancing both performance and reliability.

Product advantage

-

Fully welded

The gasket-free construction enables robust operation in higher pressure and high temperature environments, ensuring leak-resistant performance for critical applications.Easy for Cleaning

It is feature with accessible heat transfer channels, allowing for effective removal of deposits and scale through various methods like mechanical flushing, chemical cleaning, or ultrasonic cleaning. -

Openable

Bolted connection is designed to facilitate easy access and versatility by enabling all four sides to be openable. This feature allows for greater flexibility and convenience during installation, maintenance, and inspection processes.Small Footprint

Designed to occupy minimal space without compromising on capacity, significantly footprint reduction compared to traditional shell and tube heat exchanger. -

High Efficiency

Innovations in plate geometry and flow dynamics aim to further increase thermal efficiency while reducing energy consumption, aligning with global energy conservation goals.Durability

Constructed from high-quality materials and utilizing precision welding techniques, built to withstand harsh operating conditions and ensure long-term reliability.

Product Parameters

| Parameter Item | Parameter |

|---|---|

| Area | 6.6 ~ 870㎡ |

| Plate Thickness | 0.8 – 2mm |

| Design Temperature | -40 ~ 400℃ |

| Design Pressure | -0.1 ~ 4.0Mpa |

| Plate material | 304, 304L, 316L, 254SMO, C-276, Titanium |

How to design and manufacture

HT-Bloc Welded Plate Heat Exchanger

Modular Design

- Standardized Modules: HT-Bloc Welded Plate Heat Exchangers consist of interchangeable modules that can be easily added or removed based on the thermal requirements.

- Scalability: The modular nature allows for scalable solutions, accommodating varying capacities without significant redesign.

Material Selection

- Stainless Steel: Offers excellent corrosion resistance and durability, suitable for a wide range of applications.

- Titanium: Ideal for highly corrosive environments due to chloride, providing superior strength and longevity.

- Hastelloy: Utilized in extremely corrosive conditions, including acidic environments, chloride-rich media, and high temperatures.

Thermal Design

- Heat Transfer Efficiency: Optimized plate design and spacing to maximize surface area and enhance heat transfer rates.

- Flow Arrangement: Configured for multi-passes cross flow to improve thermal efficiency.

- Pressure Drop Management: Designed to minimize pressure drops, ensuring efficient fluid flow and reducing energy consumption.

Welding and Assembly Techniques

- Precision Welding: Ensures seamless connections between modules, preventing leaks and maintaining structural integrity.

- Automated Assembly: Utilizes advanced manufacturing techniques for consistent quality and rapid production.

Applications of HT-Bloc Welded Plate Heat Exchangers

As a transformative innovation in industrial thermal solutions, HT-Bloc Welded Plate Heat Exchanger redefine system optimization through their patented modular architecture and multi-process adaptability. This in-depth technical analysis examines the engineering principles behind their compact plate-and-shell configuration. Current industrial implementations span various industries due to their efficiency and versatility:

-

"Smart Eye" - Intelligent Guardian Expert for Heat ExchangersIn industrial production, the stable operation of heat exchangers is directly related to production efficiency and energy security. As a globally leading heat exchanger manufacturer, Shanghai Plate Heat Exchanger has pioneered the "Smart Eye" digital monitoring system. This system, centered on artificial intelligence, edge computing, and digital twin technologies, provides global customers with full lifecycle intelligent operation and maintenance solutions, ensuring that every heat exchanger maintains enduring vitality.

"Smart Eye" - Intelligent Guardian Expert for Heat ExchangersIn industrial production, the stable operation of heat exchangers is directly related to production efficiency and energy security. As a globally leading heat exchanger manufacturer, Shanghai Plate Heat Exchanger has pioneered the "Smart Eye" digital monitoring system. This system, centered on artificial intelligence, edge computing, and digital twin technologies, provides global customers with full lifecycle intelligent operation and maintenance solutions, ensuring that every heat exchanger maintains enduring vitality. -

Heat Exchange Solutions for Power IndustryPower industry is essential for modern life, driving economic growth and sustainability through advancements in renewable energy, smart grids, and energy storage. It plays a critical role in reducing carbon emissions and ensuring reliable energy access. Plate heat exchangers are vital in this sector, enhancing energy efficiency by optimizing heat transfer in power plants. Their compact design and high efficiency reduce energy consumption and operational costs, supporting sustainable thermal management. Together, the power industry and plate heat exchangers are key to advancing global energy solutions and achieving a greener future.

Heat Exchange Solutions for Power IndustryPower industry is essential for modern life, driving economic growth and sustainability through advancements in renewable energy, smart grids, and energy storage. It plays a critical role in reducing carbon emissions and ensuring reliable energy access. Plate heat exchangers are vital in this sector, enhancing energy efficiency by optimizing heat transfer in power plants. Their compact design and high efficiency reduce energy consumption and operational costs, supporting sustainable thermal management. Together, the power industry and plate heat exchangers are key to advancing global energy solutions and achieving a greener future. -

Heat Exchange Solutions for Offshore IndustryOffshore modular engineering is a highly technical and comprehensive project, combining specialized design, precision manufacturing, stringent quality control, and full-service after-sales support. These solutions are tailored to meet the unique demands of the marine and ship environments.

Heat Exchange Solutions for Offshore IndustryOffshore modular engineering is a highly technical and comprehensive project, combining specialized design, precision manufacturing, stringent quality control, and full-service after-sales support. These solutions are tailored to meet the unique demands of the marine and ship environments. -

HT-Bloc Welded Plate Heat Exchanger for Metallurgy IndustryThis heat exchanger is widely utilized in metallurgy such as alumina production and mining for handling challenging fluids like slurries and ore suspensions. Its robust design ensures efficient heat transfer, prevents clogging, and facilitates easy cleaning, making it an indispensable solution for demanding industrial applications..

HT-Bloc Welded Plate Heat Exchanger for Metallurgy IndustryThis heat exchanger is widely utilized in metallurgy such as alumina production and mining for handling challenging fluids like slurries and ore suspensions. Its robust design ensures efficient heat transfer, prevents clogging, and facilitates easy cleaning, making it an indispensable solution for demanding industrial applications..

Related articles

Read More

Leave Your Message

* Full Name

* Country/Region

* Email

* Company name

* Telephone Number

* Enter your needs

SHPHE has complete quality assurance system from design, manufacturing, inspection and delivery. It is certified with ISO9001, ISO14001, OHSAS18001 and hold ASME U Certificate.