How to Design a Plate Heat Exchanger

Plate heat exchangers (PHEs) are compact units con...

More

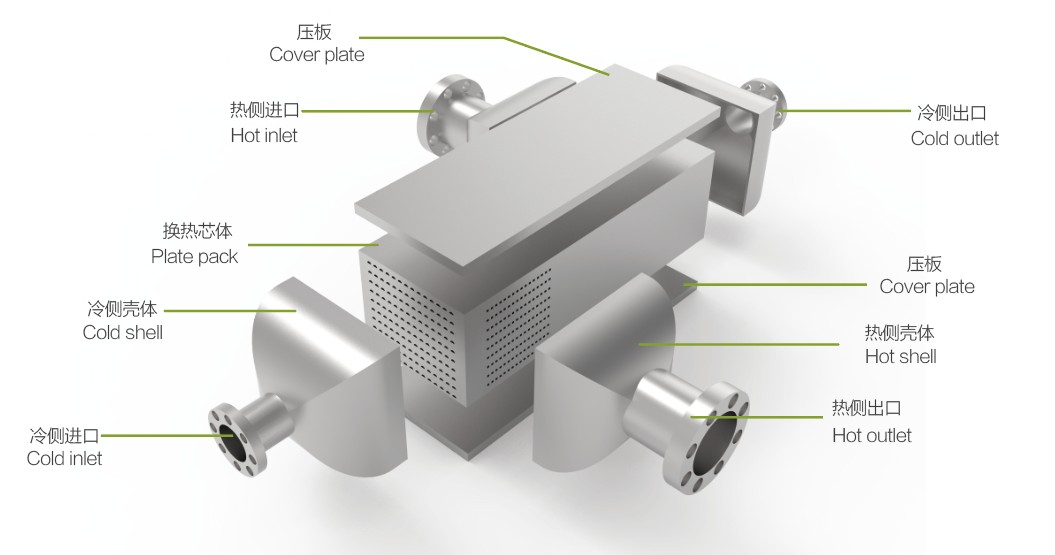

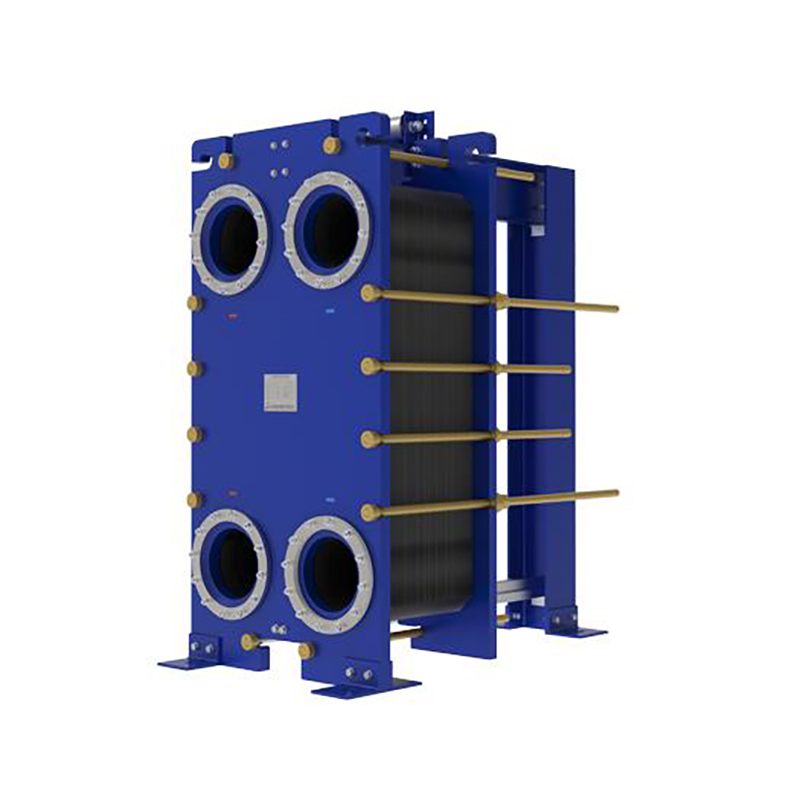

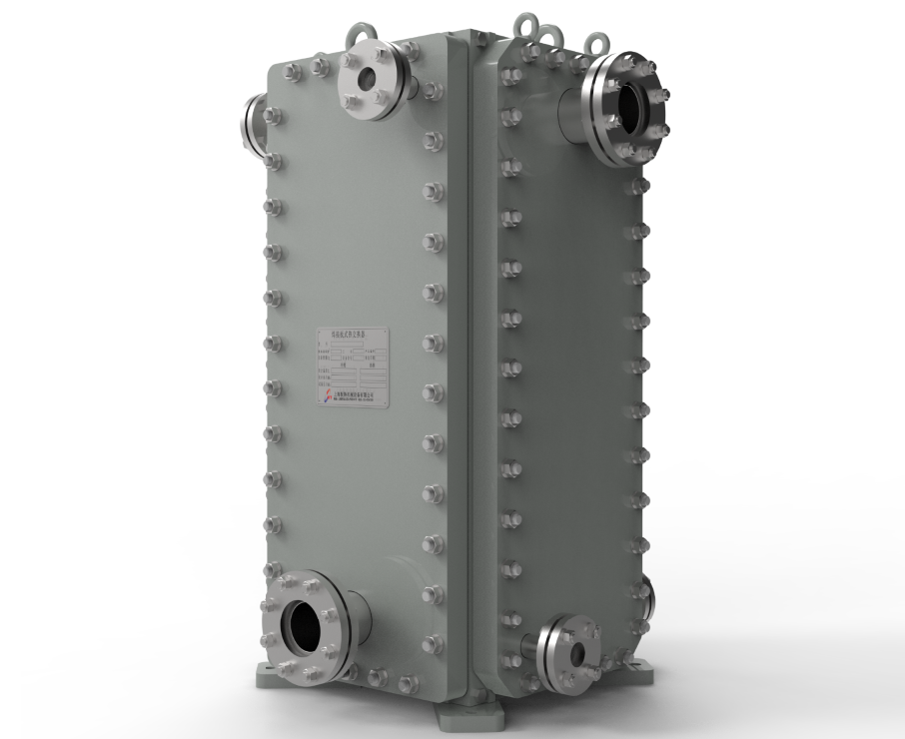

Gasketed Plate Heat Exchanger (GPHE) operates on the principle of efficient heat transfer between two fluids through a series of corrugated metal plates clamped together in a frame. These plates create alternating channels for hot and cold fluids, allowing thermal energy to move from the hotter medium to the cooler one without direct mixing. The design maximizes surface area contact while maintaining turbulent flow, which significantly enhances heat transfer coefficients compared to traditional shell-and-tube exchangers. Gaskets seal the plate edges, preventing fluid leakage and enabling customization of flow patterns for specific thermal duties. This modular arrangement supports easy expansion or maintenance by adding or removing plates, making it adaptable to varying process requirements across industries like chemical processing, HVAC, and power generation. The compact footprint and high thermal efficiency (often achieving NTU values above 3.5) make GPHEs ideal for applications where space and energy savings are critical.

The operational principle leverages the corrugated plate design to induce turbulence even at low flow rates, reducing fouling and improving heat transfer rates by up to 50% over conventional exchangers. Data from industry applications show that GPHEs can achieve overall heat transfer coefficients ranging from 3,000 to 7,000 W/m²°C for water-to-water systems, far exceeding the 800-1,500 W/m²°C typical of shell-and-tube units. The gasketed configuration allows for precise control of fluid paths, enabling parallel, counter-current, or multi-pass flows to optimize logarithmic mean temperature difference (LMTD). This flexibility supports duties in heating, cooling, and heat recovery, with approach temperatures as low as 1°C. Materials like stainless steel, titanium, or nickel alloys cater to corrosive or high-purity processes, while gaskets (e.g., NBR, EPDM, or Viton) ensure compatibility with temperatures up to 160°C and pressures to 25 bar. Real-world data from HVAC systems indicate energy savings of 15-30% due to reduced pumping needs and higher Delta T performance.

GPHEs are preferred for their unmatched combination of efficiency, scalability, and cost-effectiveness in diverse industrial sectors. Their compact design reduces installation space by up to 80% compared to shell-and-tube exchangers, lowering capital and operational costs. For instance, in the food and beverage industry, GPHEs maintain product integrity with minimal thermal degradation, handling high viscosity fluids like syrups or dairy with heat transfer rates ensuring pasteurization or cooling within seconds. Energy efficiency is a key driver; studies show that GPHEs can achieve thermal effectiveness exceeding 90% in applications like waste heat recovery, reducing fuel consumption by 20-25% in manufacturing plants. Additionally, their modularity allows easy capacity adjustments by modifying plate counts, avoiding full system replacements. In chemical processing, the ability to handle aggressive media with specialized materials minimizes downtime and maintenance, while gasket innovations reduce leakage risks. Data from power plants highlight a 15% reduction in cooling water usage and 10% lower carbon emissions due to optimized heat recovery. With lifecycle costs up to 30% lower than alternatives and compliance with ASME and PED standards, GPHEs offer reliability and sustainability, making them ideal for modern, eco-conscious industries seeking to enhance process efficiency and reduce environmental impact.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchangers (PHEs) are compact units con...

More

Industrial users gain significant value from a gas...

More

This guide offers a comprehensive examination of t...

More

Industries in 2025 achieve higher efficiency by ad...

More

Understanding welded heat exchanger's unique const...

More

Plate Heat Exchangers (PHEs) are pivotal component...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Reynolds

Maintenance SupervisorThis gasketed plate heat exchanger is incredibly efficient and robust. The compact design saved us a significant amount of space, and the plates are easy to access for maintenance. It has handled our high-temperature duties without any issues. A fantastic piece of equipment.

Sarah Chen

Plant EngineerWe installed this unit for a pasteurization application, and the performance has been outstanding. The heat transfer is excellent, leading to greater energy efficiency. The gasketed design makes cleaning and inspection a straightforward process. Highly recommended for food and beverage applications.

David Miller

HVAC TechnicianA very reliable and effective plate heat exchanger for our district heating system. It integrates well and performs as advertised. The only minor drawback was a longer-than-expected delivery time, but the product quality itself is top-notch.

Jessica Williams

Process EngineerThis exchanger has drastically improved the thermal efficiency of our waste heat recovery loop. The ability to add or remove plates to adjust capacity is a huge advantage for our evolving process needs. A durable and well-engineered solution.