Media

Find by news

Exploring the Top Uses of Stainless Steel Plate Heat Exchangers

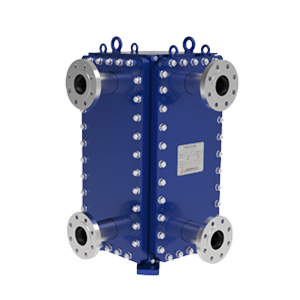

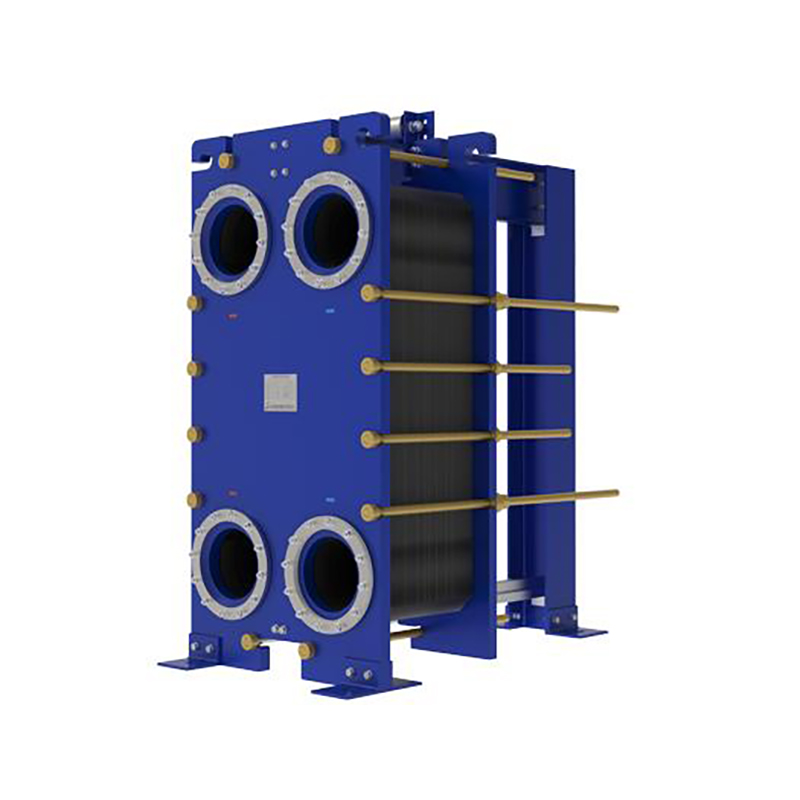

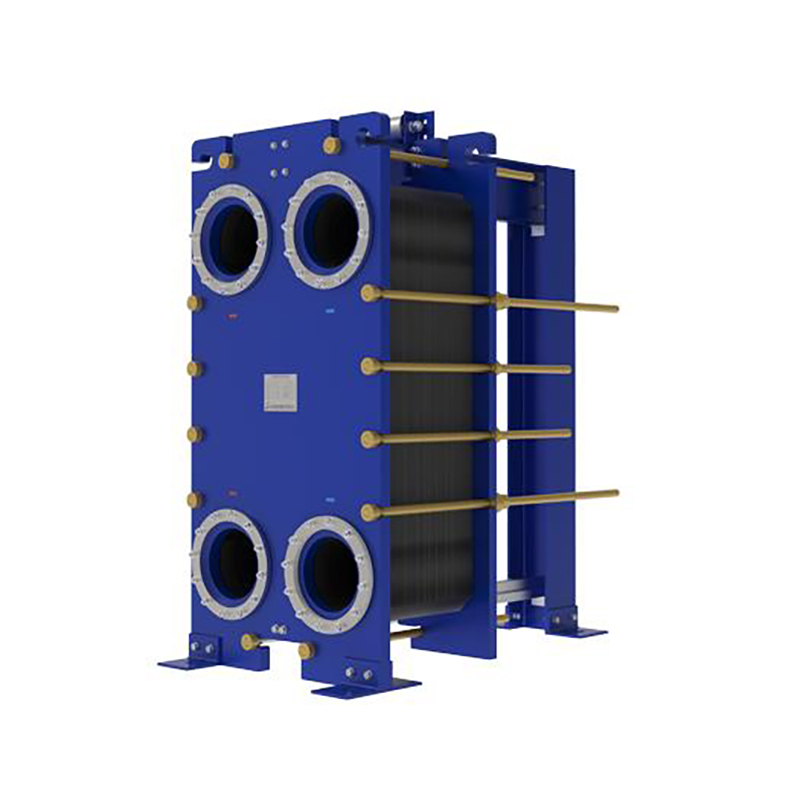

Shanghai Plate Heat Exchanger introduces the HT-Bloc Welded Plate Heat Exchanger, an innovative solution that combines robust stainless steel construction with advanced engineering. Stainless steel plate heat exchangers continue to lead the market due to their adaptability and reliability.

Dec-30-2025

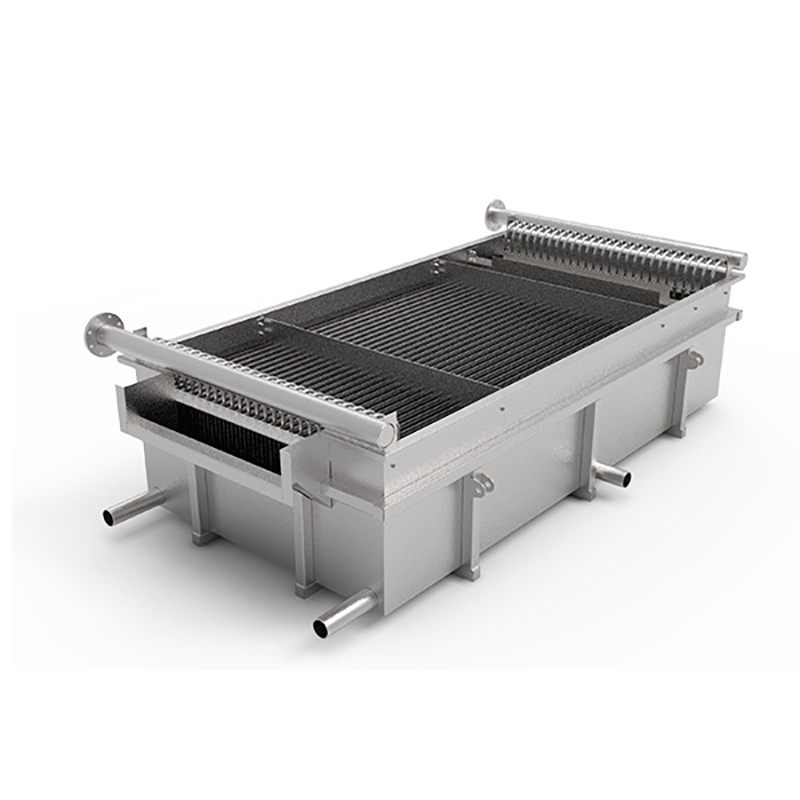

Dimple plate heat exchanger delights and dilemmas for every user

The dimple plate heat exchanger, also known as the Pillow Plate, stands out for its innovative structure and energy-saving performance. SHPHE’s Pillow Plate offers users high versatility across industries, with smooth surfaces that simplify cleaning and maintenance. Users often favor this technology in food, chemical, and environmental sectors. However, some may encounter challenges related to installation complexity and system size.

Dec-29-2025

Are Titanium Heat Exchangers Worth the Investment

Shanghai Heat Transfer’s TP Welded Plate Heat Exchanger showcases advanced titanium solutions. Many professionals see high upfront costs, but long-term savings, safety, and low maintenance make titanium a smart investment.

Dec-26-2025

Industries Benefiting from Printed Circuit Heat Exchangers

Shanghai Plate Heat Exchanger leads the market with innovative printed circuit heat exchanger designs, supporting a wide range of industries.

Dec-25-2025

How to Choose the Right OEM Pillow Plate Supplier for Your Project

Choosing a supplier without these qualities can lead to costly delays or quality issues. Careful evaluation brings long-term value and peace of mind. Many trust brands like shphe for their consistent performance and commitment to excellence.

Dec-24-2025

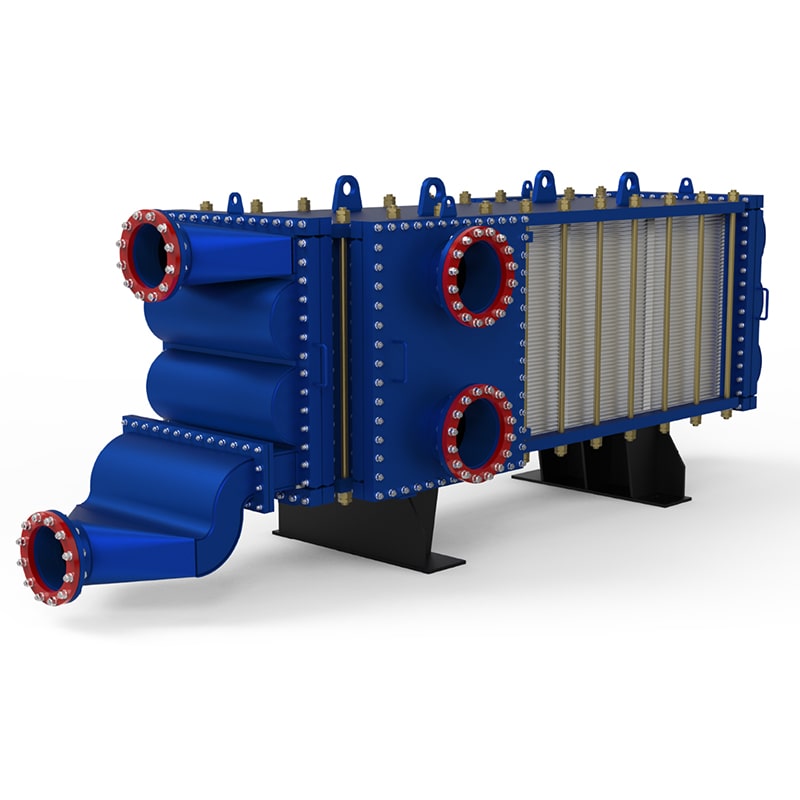

How different heat exchanger types are applied across major industries

Plate heat exchangers are becoming more popular because they are small and work well. Shanghai Heat Transfer is a top company for plate heat exchangers. They have many products and smart solutions.

Dec-23-2025

Thermal Exchanger Types You Should Know and Their Unique Benefits

Choosing the right thermal exchanger can lower operational costs, improve energy efficiency, and help companies meet strict standards. Shanghai Plate Heat Exchanger leads with innovative solutions like the Wide Gap Welded Plate Heat Exchanger, designed for demanding environments.

Dec-22-2025

Top Industries Revolutionizing Heat Exchange System Applications

Shanghai Plate Heat Exchanger stands at the forefront, leveraging Printed Circuit Heat Exchanger technology to deliver robust performance and compact designs. The latest advancements enhance applications across sectors, with PCHEs offering high efficiency and reliability under extreme conditions.

Dec-19-2025

How to Select the Right Compact Heat Exchanger for Your Needs in 2025

To select the right compact heat exchanger, users match process, fluid, space, and maintenance needs to available options. A compact heat exchanger provides efficient and reliable thermal management across industries like oil and gas, chemical, and food processing. Shanghai Heat Transfer’s TP Welded Plate Heat Exchanger offers innovative solutions.

Dec-18-2025

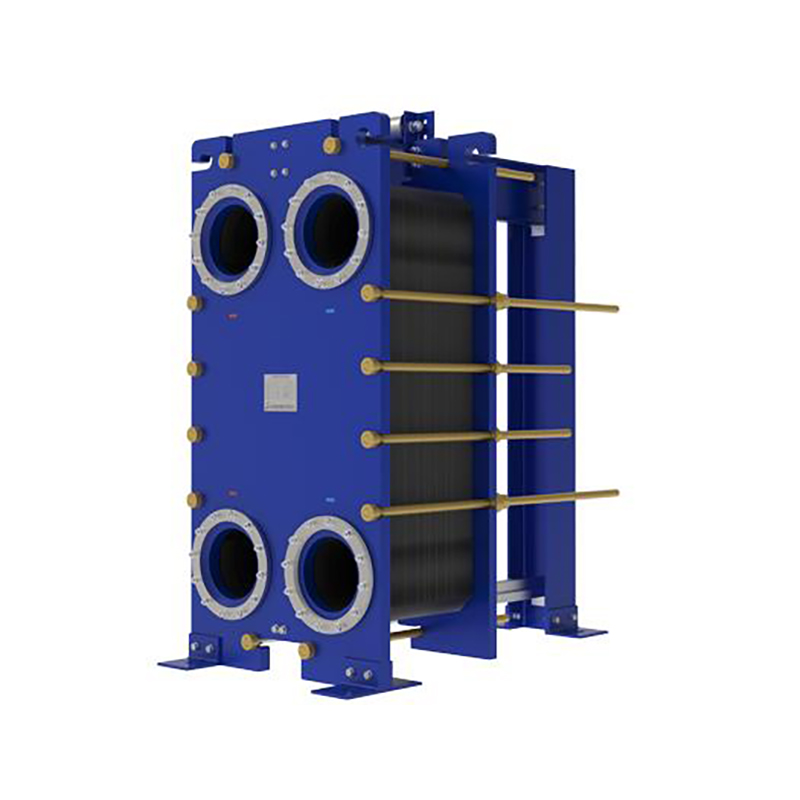

What Most People Miss About Gasketed Heat Exchanger

a gasketed heat exchanger offers impressive heat transfer rates but requires careful attention over time. Users often focus on immediate performance and miss the impact of maintenance in their daily operations. Shanghai Heat Transfer provides expert guidance to help industries choose the right gasketed plate heat exchanger

Dec-17-2025

SHPHE has complete quality assurance system from design, manufacturing, inspection and delivery. It is certified with ISO9001, ISO14001, OHSAS18001 and hold ASME U Certificate.