Media

Find by news

Top Stainless Steel Heat Exchanger Producers of the Year

The best manufacturers of stainless heat exchanger products in 2025 lead with innovation, energy efficiency, and a focus on sustainability. Stainless steel heat exchangers power critical sectors, including power generation, chemical processing, oil and gas, and HVAC systems, where demand keeps rising.

Dec-16-2025

How Laser Welded Plate Technology Is Shaping the Future

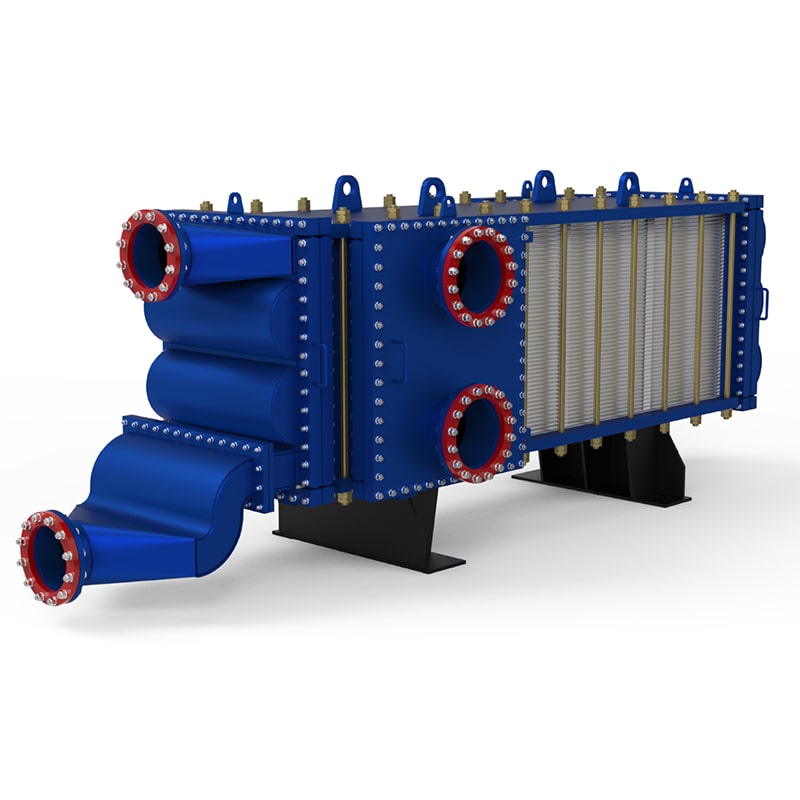

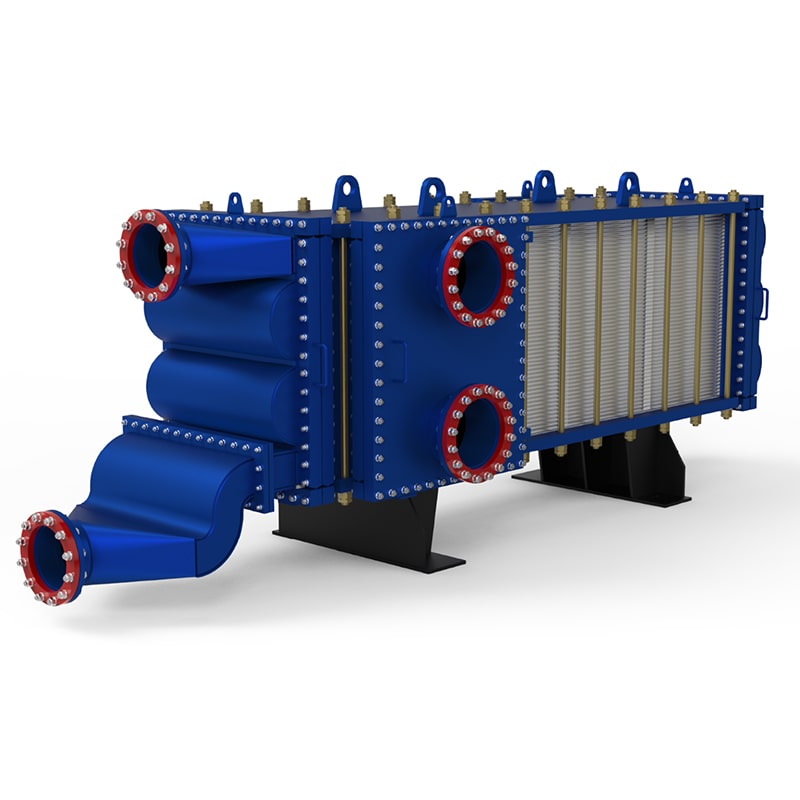

Shanghai Plate Heat Exchanger leads innovation with the Wide Gap Welded Plate Heat Exchanger, setting new standards for reliability and performance.

Dec-15-2025

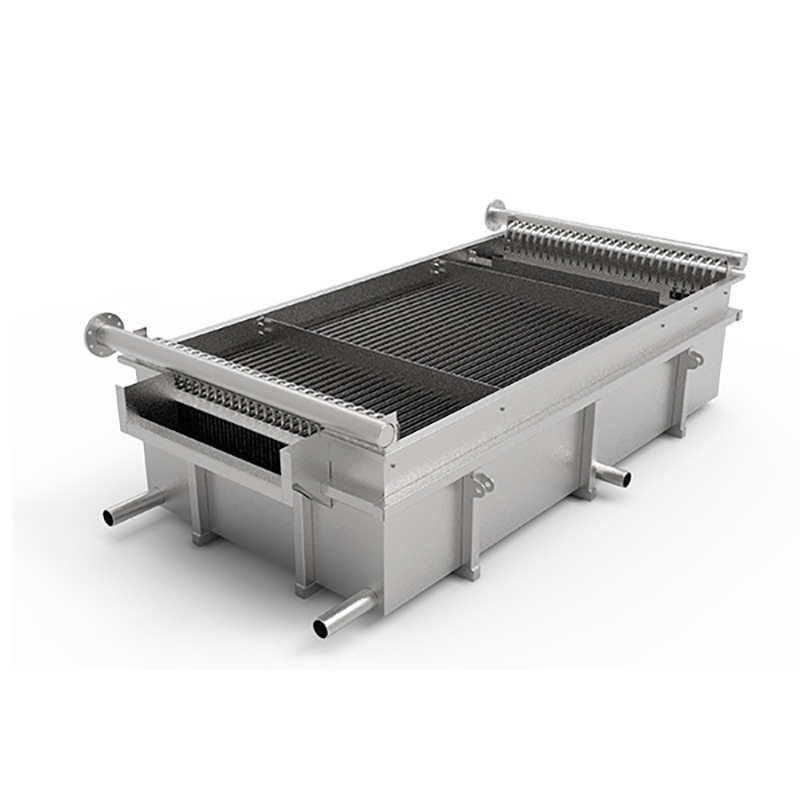

How Pillow Plates Improve Efficiency in Heat Exchangers

Pillow plate technology from Shanghai Heat Transfer sets a new standard in heat exchanger efficiency. The innovative design features an internal cavity structure that maximizes heat transfer and mechanical strength.

Dec-12-2025

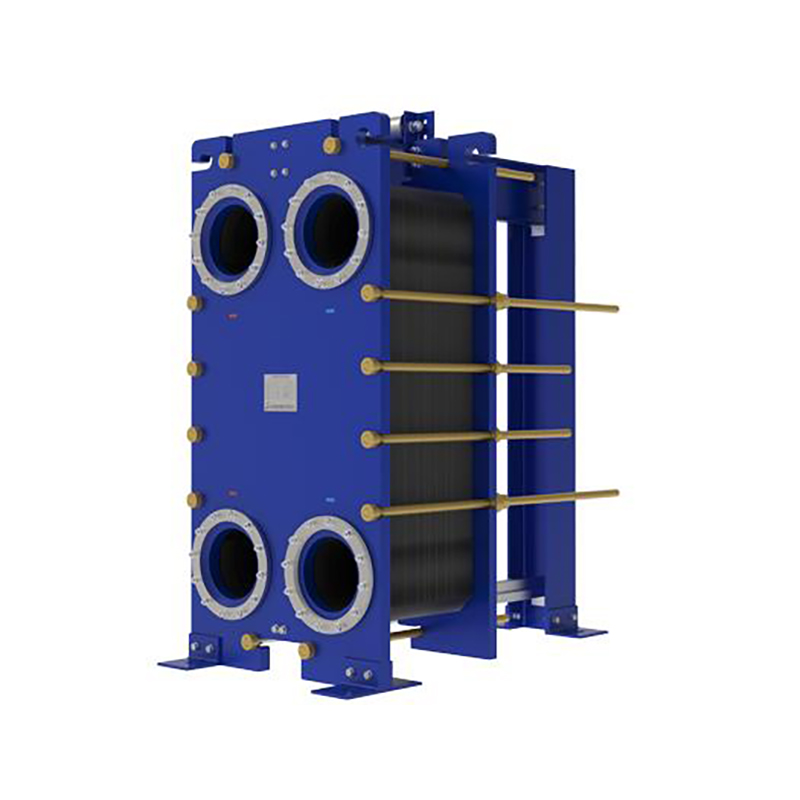

How to Assess Plate Heat Exchanger Manufacturers for Quality and Service

Choosing the correct plate heat exchanger manufacturer protects systems from costly failuresShanghai Heat Transfer demonstrates a strong commitment to service and support.

Dec-11-2025

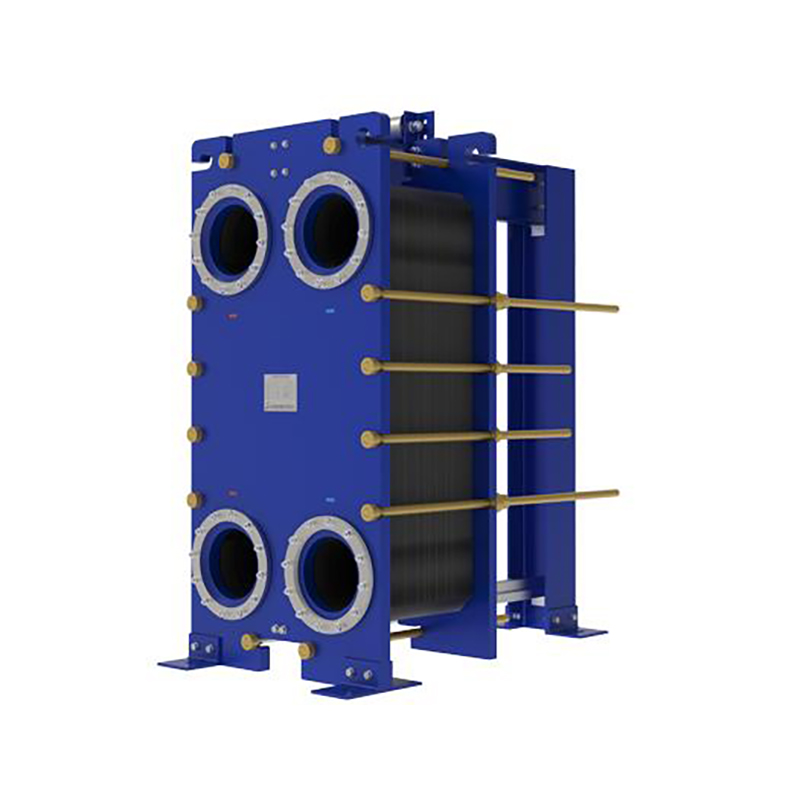

Best Gasketed Heat Exchanger Designs for Modern Factories

Factories in 2025 rely on advanced gasketed heat exchanger designs that deliver high efficiency, flexibility, and reliability. Modular plate heat exchangers, especially those with innovative features, now dominate industrial settings.

Dec-10-2025

How to Identify the Perfect Titanium Plate Heat Exchanger for Corrosive Environments

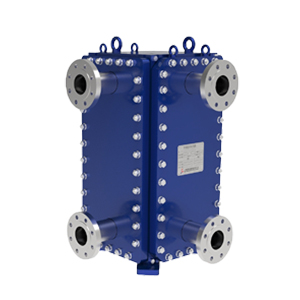

The HT-Bloc Welded Plate Heat Exchanger from Shanghai Plate Heat Exchanger features advanced plate design and titanium construction, offering reliable performance in demanding applications.

Dec-09-2025

What Makes Modern Pillow Plate Heat Exchangers More Efficient

Modern pillow plate heat exchangers achieve higher efficiency through innovative internal cavity design, advanced materials, and digital integration. Shanghai Heat Transfer's Pillow Plate features laser-welded geometries and IoT monitoring, which support exceptional energy savings and durability.

Dec-08-2025

Essential Manual for Gasket Heat Exchanger Installation

Proper gasket installation in a gasket heat exchanger protects equipment and people. Incorrect placement or damaged gaskets may cause leaks or even equipment failure. Careful attention during each step ensures the heat exchanger operates safely and efficiently. Regular inspection of every gasket keeps the system reliable for years.

Dec-05-2025

The Complete Guide to Welded PHE Selection for Industrial Use

Advanced heat exchanger solutions like the TP Welded Plate Heat Exchanger from Shanghai Heat Transfer offer reliable and durable options for demanding applications. Their innovative solutions help industries achieve high efficiency and long-term reliability.

Dec-04-2025

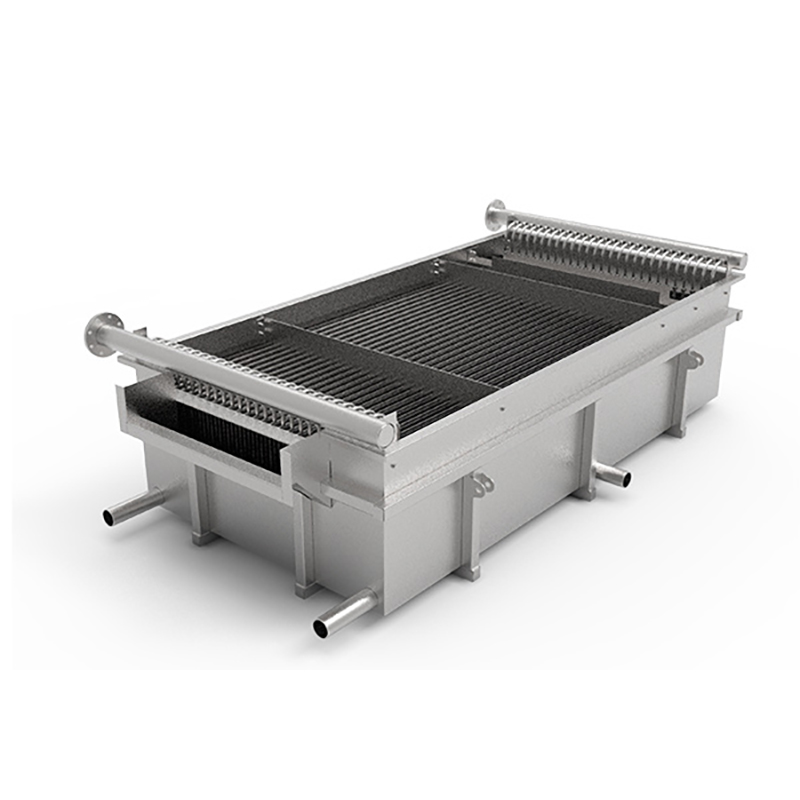

Expert Advice on Cleaning and Maintaining Plate Air Preheaters

Shanghai Heat Transfer designs its Plate Air Preheater with a modular structure and high corrosion resistance. These features simplify maintenance and extend service life. Many industry professionals rely on Shanghai Heat Transfer for dependable technology and expert support.

Dec-03-2025

SHPHE has complete quality assurance system from design, manufacturing, inspection and delivery. It is certified with ISO9001, ISO14001, OHSAS18001 and hold ASME U Certificate.