Gaskets for Plate Heat Exchangers: What are They Made of?

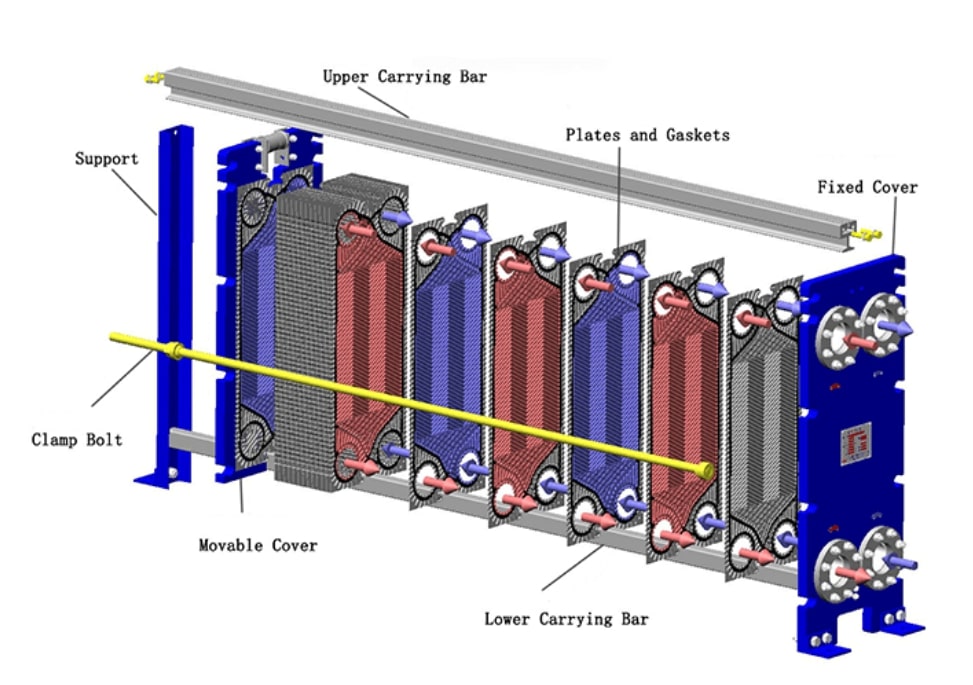

Plate heat exchangers (PHEs) are compact devices that transfer heat between two fluids via a stack of thin metal plates. In a gasketed plate heat exchanger, each plate has grooves that hold an elastomeric gasket, and the plates are clamped together in a frame. This design forces the two fluids to flow in alternating channels (often counter-currently), maximizing the temperature difference and heat transfer efficiency. The gaskets prevent leaks and keep the hot and cold fluids separate.

PHEs are used in many industries – from HVAC and refrigeration to chemical processing and food/beverage production. In hygienic applications (dairy, food, beverage, pharma), gaskets must meet strict cleanliness and FDA (food-grade) standards. The choice of gasket material affects not just sealing performance but also long-term reliability. Common gasket materials include EPDM (ethylene-propylene-diene monomer), NBR (nitrile-butadiene rubber), and Viton® (fluoroelastomer, FKM). Each has different temperature limits and chemical compatibilities.

Role of Gaskets in Plate Heat Exchangers

Gaskets serve as the seal between each pair of plates. As the fluids enter the plate pack through the inlet ports, gaskets ensure they stay in their proper channels and exit through the correct outlets. By creating a tight seal, gaskets keep the two fluids completely separate and prevent any mixing. This separation is crucial: any leak or cross-contamination would drastically reduce thermal efficiency and could ruin product quality.

Nitrile/EPDM/Viton gaskets for easy maintenance.

A cutaway schematic of a gasketed plate heat exchanger. Alternating red and blue channels show the hot and cold fluid streams, separated by elastomeric gaskets (dark gray) between each plate. The plate stack is clamped by bolts and supported by carrying bars.

In addition to sealing, gaskets protect the plate edges from debris and cleaning chemicals. A well-chosen gasket material resists fouling and the caustic or acidic solutions used in cleaning procedures. In effect, the gaskets help maintain clean flow passages and extend equipment life by minimizing maintenance and downtime. Without reliable gaskets, a plate exchanger quickly loses efficiency or needs frequent unscheduled servicing.

Gasket Material Of Plate Heat Exchanger

Plate heat exchanger gaskets are typically made from one of three elastomer families. Each is chosen based on the fluids and conditions it must withstand:

EPDM (Ethylene-Propylene-Diene Monomer) – EPDM is a synthetic rubber valued for its resistance to heat, water, and steam. It can generally handle service temperatures from about –25 °C up to roughly 150–180 °C. EPDM resists hot water, steam, many acids and alkalis (except strong oxidizers), and even ozone or sunlight. This makes it common in hot-water heating, low-pressure steam, refrigeration (glycol loops), and sanitary (food/dairy) processes. However, EPDM is attacked by petroleum oils and organic solvents – it will swell and deteriorate if exposed to fuels.

NBR (Nitrile-Butadiene Rubber) – Nitrile (Buna-N) is prized for its oil and fuel resistance. It remains stable and elastic from roughly –15 °C up to about 110–140 °C. NBR gaskets are typically used when fluids include oils, fuels, lubricants, or water-miscible coolants. They seal well in engine oil coolers, hydraulic oil heat exchangers, and fuel-handling systems. NBR can handle hot water and saltwater, but it degrades in strong acids and cannot withstand high-temperature steam.

Viton® (Fluoroelastomer, FKM) – Viton is a premium rubber with outstanding thermal and chemical resistance. It tolerates a wide range (typically –15 °C up to about 180 °C). Viton gaskets resist strong acids (e.g. sulfuric acid), caustic solutions (sodium hydroxide), hydrocarbons, fuels, and high-temperature heat transfer oils. They are commonly used in chemical plants, refineries, and anywhere process fluids are highly aggressive. Viton’s downsides are higher cost and stiffness: it is harder to compress and requires higher clamping force.

In practice, the gasket choice often follows the media:

Hot water or steam? Use EPDM.

Oil or gasoline? Use NBR.

Harsh chemicals or very high heat? Use Viton.

Matching the gasket material to the fluids prevents premature degradation and ensures a reliable seal.

Technical Considerations in Gasket Selection

Design Temperature and Pressure:

Every exchanger has maximum operating conditions. For example, many gasketed PHEs are rated up to ~180 °C and 36 bar. The gasket material must tolerate the maximum process temperature (with a safety margin). EPDM’s upper limit is ~150–180 °C, NBR’s ~110–140 °C, and Viton’s ~180 °C. Likewise, the gasket must seal under the system pressure; very high pressures (tens of bar) demand a durable elastomer that won’t extrude or leak.

Chemical Resistance and Cleaning Compatibility: Industrial Heat exchangers often undergo automated cleaning with strong alkalis, acids, and detergents. Gaskets must resist both the process fluids and cleaning agents. EPDM tolerates many alkali cleaners and mild acids commonly used in CIP cleaning solution, as well as steam washdowns. NBR is less resistant to alkaline/acidic cleaners and is attacked by solvents. Viton can withstand virtually all CIP chemicals without damage.

Food-Grade and Regulatory Requirements: In food, dairy, beverage, and pharma applications, gaskets must meet FDA or EU food-contact standards. Food-grade EPDM and NBR compounds (often white or certified black rubbers) are widely available and compliant with FDA 21 CFR or EU regulations. Specialty Viton grades (for example, white FDA-approved FKM) are also offered for sanitary services. Always verify the gasket material has the necessary food-safety certification for the intended application.

Thermal and Mechanical Stability: Gaskets are elastomers and will age over time, especially under heat and mechanical stress. Key properties include compression set (permanent deformation after being clamped) and resistance to thermal aging. Elastomers like EPDM and Viton are formulated for good aging performance; NBR at high temperatures can lose elasticity more quickly. Hardness (durometer) is also important: typical PHE gaskets are around 60–75 Shore A. The gasket shape (clip-on, full-face, etc.) must match the plate’s design and allow proper compression to seal without extruding.

By carefully matching the gasket material to the operating profile (temperature, pressure, chemicals, and cleaning regimen), one ensures that the seal remains tight and the exchanger performs efficiently.

Material Comparison: EPDM vs NBR vs Viton

The table below compares key characteristics and applications of the three common gasket materials:

Property/Characteristic | EPDM | NBR (Nitrile) | Viton® (FKM) |

Typical Temp Range | –40 °C to +150–180 °C | –20 °C to +110–140 °C | –15 °C to +180 °C |

Water/Steam Service | Excellent (steam, hot water) | Good (cold to warm water) | Good (handles hot water; some steam) |

Oil/Fuel Resistance | Poor (swells in petroleum oils) | Excellent (fuels, lubricants) | Excellent (fuels, aromatics) |

Acid/Alkali Resistance | Good (many acids/alkalis; see note) | Poor (sensitive to strong acids/alkalis) | Excellent (resists strong acids/alkalies) |

CIP Compatibility | High (resists caustics, many cleaners) | Limited (avoid strong caustics/acid) | Very high (resists aggressive detergents) |

Food-Grade Available | Yes (FDA/EU-approved grades exist) | Yes (available in food-grade compounds) | Yes (available in specialty food-grade) |

Mechanical Properties | Flexible/resilient; good low-temp flexibility | Good abrasion resistance; higher tensile strength | Stiffer (higher hardness); high tensile strength |

Typical Applications | Hot water/steam systems, sanitation | Oil/fuel coolers, hydraulic systems | Chemical processing, petrochemical |

Advantages | Low cost; excellent weather/ozone resistance | Outstanding oil/fuel compatibility; economical | Outstanding heat/chemical resistance; durable in harsh environments |

Limitations | Attacked by hydrocarbons; limited high-temp use | Not for high-temp steam or strong chemicals | Higher cost; stiffer (needs more clamp force) |

Comparison of typical properties and media compatibilities for EPDM, NBR, and Viton gasket materials.

EPDM excels with hot water and steam (making it ideal for HVAC or food pasteurization),

NBR excels with oils and fuels (common in automotive or hydraulic coolers),

and Viton handles aggressive chemicals and high heat (used in refineries and chemical plants). Selecting the material that matches the process fluids and conditions prevents premature gasket failure and leakage.

Ensuring Efficiency and Longevity

Choosing the right gasket material is critical for efficient, long-lasting operation. A properly matched gasket maintains its seal under pressure and heat without rapid degradation. For example, using EPDM in an oil heater would cause it to swell and leak; using NBR with 150 °C steam would cause it to dry out and crack. Both mistakes lead to unscheduled shutdowns and costly repairs.

When a gasket is compatible with the fluids and cleaning chemicals, the exchanger runs at its designed capacity with minimal leakage and maintenance. Such gaskets endure many thermal cycles and clean-in-place routines while retaining elasticity. This minimizes energy losses (from bypassing leaks) and prevents cross-contamination of fluids. Over time, the right gasket selection boosts uptime and extends maintenance intervals.

Choose the Right Gasket Material

Gaskets may seem like minor parts of a plate heat exchanger, but they are essential to its function. By sealing the plates, gaskets enable the compact, high-efficiency heat transfer that PHEs provide. The right gasket material depends on the application: one must consider temperature, pressure, chemical environment, cleaning procedures, and regulatory needs.

When properly chosen and maintained, a gasketed plate heat exchanger will run reliably and efficiently for years.

If you need further consultation and discussion, please feel free to contact us.

Email: info@shphe.com

WhatsApp / Cell: +86 15201818405