News

Find by news

How to Design a Plate Heat Exchanger

Plate heat exchangers (PHEs) are compact units consisting of thin, corrugated metal plates stacked together. These plates create alternating channels for hot and cold fluids to flow. The fluids stay separate (thanks to gaskets or welded seals) and typically flow in counter-current mode, maximizing the temperature difference along the length.

Apr-30-2025

Critical Roles of Plate Heat Exchangers in Modern Industries

Their adaptability and efficiency make PHEs a go-to solution for modern industrial thermal challenges, highlighting their importance in manufacturing, energy, and environmental industires.

Apr-28-2025

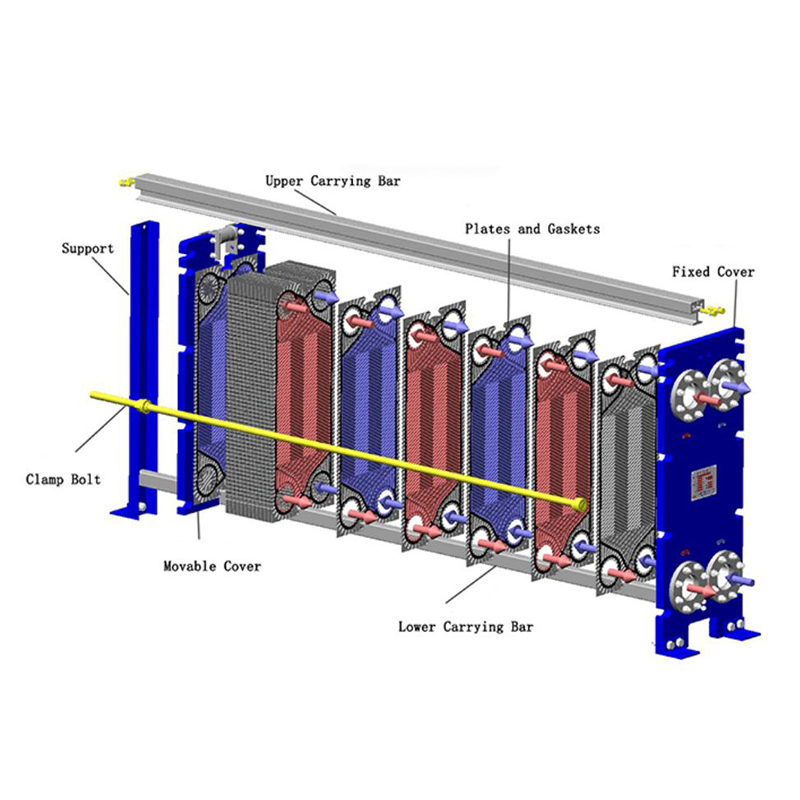

How To Assemble Plate Type Heat Exchanger

This guide offers a comprehensive examination of the best practices for the assembly and installation of gasketed plate heat exchanger, ensuring that your system functions at maximum effectiveness from the outset.

Apr-28-2025

How to Check if Your Plate Heat Exchanger is Blocked?

Blocked PHEs can significantly reduce performance, increase energy consumption, and lead to costly downtime or even equipment failure. Early detection is crucial for maintaining system integrity and optimizing operational costs. But how can you definitively tell if your welded or gasketed plate heat exchanger is blocked?

Apr-21-2025

Advantages of Welded Plate Heat Exchangers

Understanding welded heat exchanger's unique construction and advantages is crucial for industries seeking optimal thermal performance and long-term reliability.

Apr-21-2025

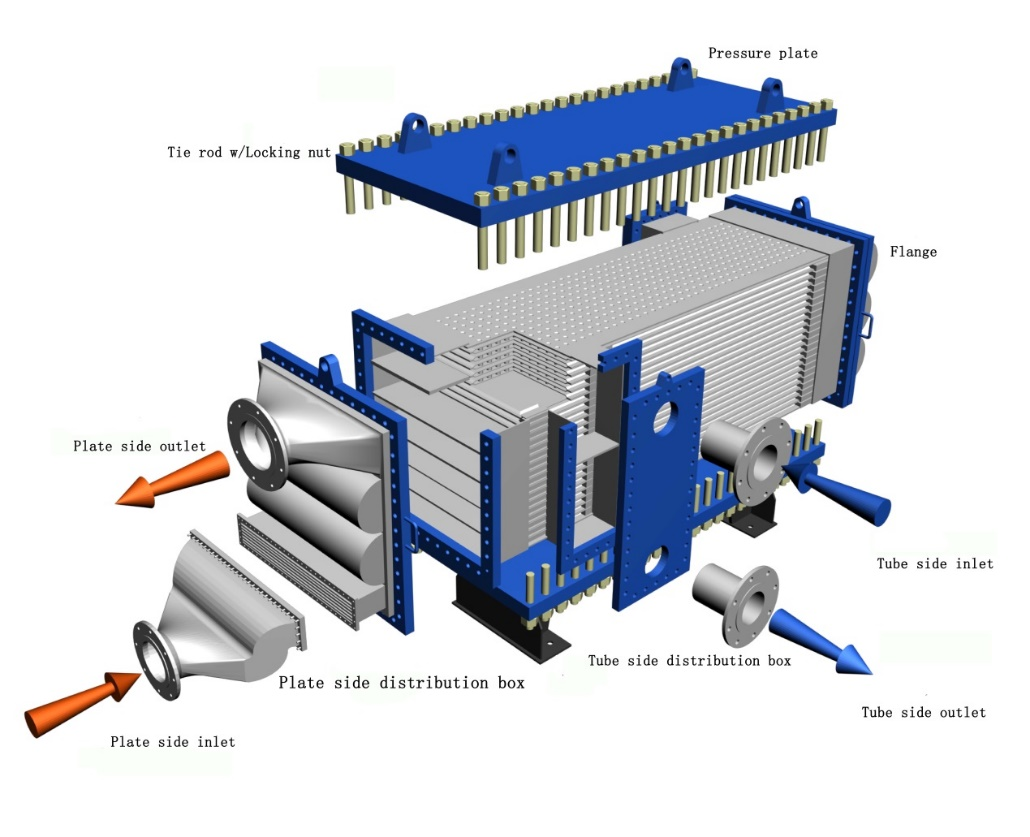

Why Choose HT-BLOC Fully Welded Plate Heat Exchanger?

Traditional plate heat exchangers (PHEs) use gaskets to seal between plates. While these designs are effective in standard conditions, they inherently limit performance at elevated pressures or temperatures and can degrade in chemically harsh environments. By contrast, the HT-Bloc unit uses fully welded plate construction, employing laser or plasma welding to bond metal plates without any gaskets within the heat transfer pack.

Apr-21-2025

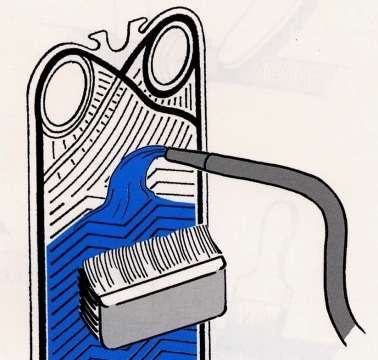

Step-by-Step Cleaning Process for Plate Heat Exchangers

Plate heat exchangers (PHEs) are vital components in various industrial processes, facilitating efficient heat transfer between fluids. Over time, these systems can accumulate fouling—such as mineral scaling, biological growth, and particulate matter—that impairs performance. Regular cleaning is essential to maintain optimal functionality and extend the lifespan of the equipment.

Apr-14-2025

How To Choose/Select a Plate Heat Exchanger

Plate Heat Exchangers (PHEs) are pivotal components in thermal management systems, facilitating efficient heat transfer between two fluids without direct contact. Comprising a series of thin, corrugated metal plates, these exchangers create alternating channels for hot and cold fluids, maximizing the surface area for heat exchange. This design not only enhances thermal efficiency but also allows for a compact footprint, making PHEs ideal for applications where space is at a premium.

Apr-14-2025

The Superiority of Plate Heat Exchangers in Modern Applications

A plate heat exchanger (PHE) is a device engineered to transfer thermal energy between two fluids without allowing them to mix. It comprises a series of thin, corrugated metal plates that create separate channels for each fluid. These plates are assembled in a frame, forming parallel flow paths that facilitate efficient heat exchange. The design ensures a large surface area within a compact footprint, making PHEs highly effective in various industrial applications.

Apr-10-2025

What Are The Different Types of Heat Exchanger?

In the intricate tapestry of industrial operations and everyday conveniences, heat exchangers emerge as pivotal components, orchestrating the seamless transfer of thermal energy between mediums. These devices are indispensable, ensuring processes operate within desired thermal parameters, thereby optimizing efficiency and safety.

Apr-10-2025

SHPHE has complete quality assurance system from design, manufacturing, inspection and delivery. It is certified with ISO9001, ISO14001, OHSAS18001 and hold ASME U Certificate.