SHPHE received repeat order from customer in Australia

Recently, SHPHE received repeat order from custome...

More

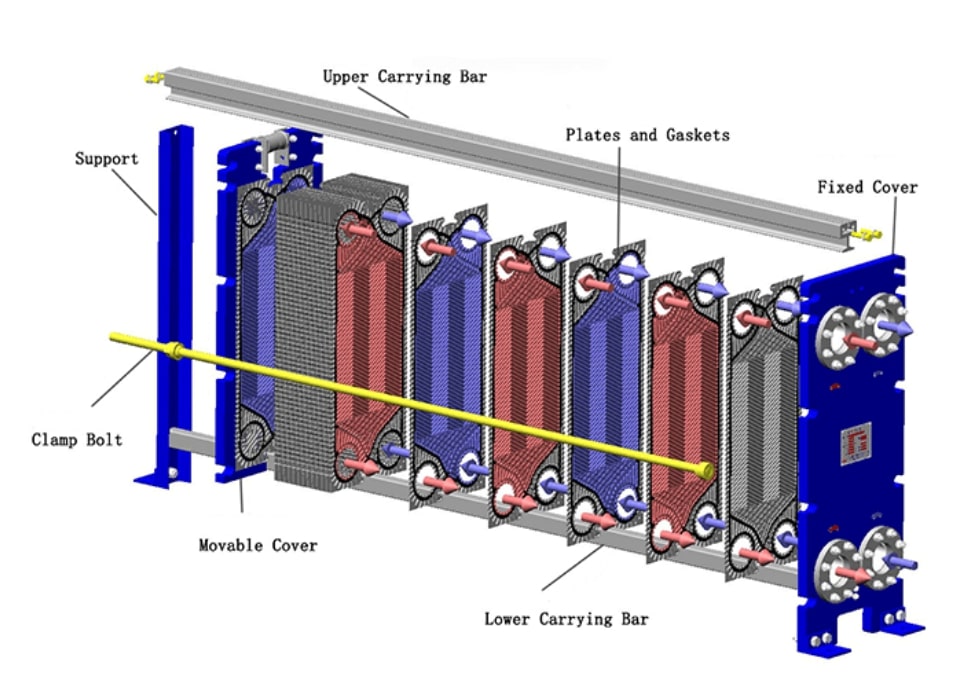

A chilled water plate heat exchanger is a highly efficient thermal transfer device designed to cool or heat fluids in industrial, commercial, and HVAC systems. It consists of multiple thin, corrugated metal plates stacked together, creating alternating channels for hot and cold fluids to flow without mixing. These exchangers are widely used in data centers, manufacturing plants, and district cooling systems due to their compact design, superior heat transfer efficiency, and low energy consumption. Compared to traditional shell-and-tube heat exchangers, plate models offer up to 50% better thermal performance while occupying 80-90% less space. Common materials include stainless steel (AISI 304/316) for corrosion resistance and titanium for seawater applications.

Chilled water plate heat exchangers operate on the principle of conductive and convective heat transfer between two fluids separated by metal plates. As chilled water (typically at 6-12°C) flows through alternate channels, it absorbs heat from the warmer process fluid (e.g., 25-35°C glycol solution) in adjacent channels. The corrugated plate pattern creates turbulent flow, enhancing heat transfer coefficients to 3,000-7,000 W/m²K – 3-5 times higher than shell-and-tube designs. Gasketed models allow easy disassembly for cleaning, while brazed versions (with copper or nickel solder) handle higher pressures up to 30 bar. Modern units achieve approach temperatures as low as 1-2°C, with typical heat recovery rates exceeding 90%. Variable plate geometries optimize performance for specific applications, such as high ΔT scenarios in beverage cooling or precise temperature control in pharmaceutical processes.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Recently, SHPHE received repeat order from custome...

More

Traditional plate heat exchangers (PHEs) use gaske...

More

This guide offers a comprehensive examination of t...

More

Understanding welded heat exchanger's unique const...

More

Plate heat exchangers (PHEs) are often the most ef...

More

A plate heat exchanger (PHE) is a device engineere...

MoreExplore more content related to foreign trade services