Advantages of Welded Plate Heat Exchangers

Understanding welded heat exchanger's unique const...

More

An engine oil heat exchanger is a critical component designed to regulate the temperature of engine oil by transferring excess heat to a cooling medium, such as coolant or air. This ensures optimal oil viscosity, reduces thermal degradation, and enhances engine efficiency. Commonly used in automotive, marine, and industrial applications, heat exchangers help maintain engine reliability and prolong the lifespan of lubricants. By preventing overheating, they minimize wear on engine components, improve fuel economy, and reduce emissions. Modern designs include shell-and-tube, plate-and-frame, and finned-tube configurations, each tailored for specific performance requirements.

Engine oil heat exchangers play a vital role in maintaining engine health by stabilizing oil temperatures under extreme operating conditions. In high-performance vehicles or heavy machinery, oil temperatures can soar, leading to thinning and loss of lubricating properties. The heat exchanger counteracts this by cooling the oil, ensuring it remains within the ideal 180–220°F (82–104°C) range. Studies show that properly cooled oil can reduce engine wear by up to 50% and extend oil change intervals by 30%. Additionally, heat exchangers recover waste heat in some systems, improving overall energy efficiency. Brands like Hayden, Derale, and Modine offer advanced models with corrosion-resistant materials like aluminum or stainless steel for durability.

Engine oil heat exchangers operate on the principle of thermal exchange between hot oil and a cooler fluid. In liquid-cooled systems, engine coolant circulates through the exchanger, absorbing heat from the oil. Air-cooled variants use fins to dissipate heat into the surrounding air. The process involves directing oil through a series of channels or plates while the cooling medium flows in a separate, adjacent path, facilitating efficient heat transfer without fluid mixing. Thermostatic valves often regulate flow to maintain consistent temperatures.

The efficiency of an engine oil heat exchanger depends on factors like surface area, flow rate, and temperature differential. For example, plate-type exchangers achieve 90%+ thermal efficiency due to their large contact surfaces. In turbocharged engines, oil temperatures can exceed 250°F (121°C), but heat exchangers reduce this by 20–40°F (11–22°C), as documented in SAE International studies. Some systems integrate bypass valves to prevent overcooling in cold starts. Advanced computational fluid dynamics (CFD) optimize designs for minimal pressure drop (typically <10 psi) while maximizing heat dissipation. Regular maintenance, such as cleaning fins or checking for coolant leaks, ensures peak performance and prevents clogging from oil sludge.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Understanding welded heat exchanger's unique const...

More

Recently, SHPHE received repeat order from custome...

More

PCHEs routinely operate at temperatures up to 850 ...

More

This guide offers a comprehensive examination of t...

More

Plate heat exchangers (PHEs) are often the most ef...

More

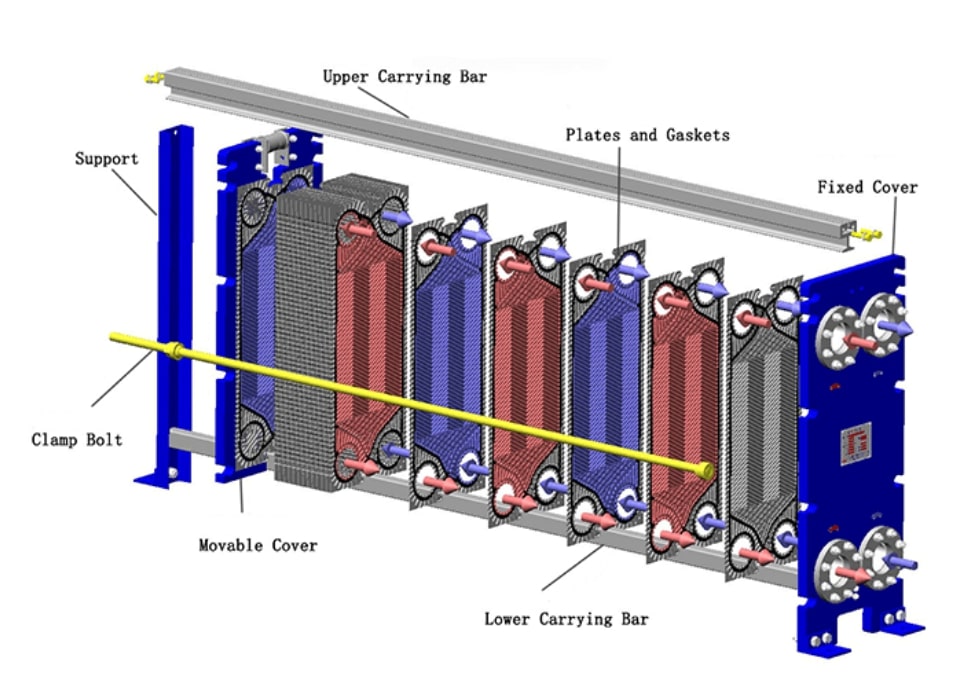

A plate heat exchanger (PHE) is a device engineere...

MoreExplore more content related to foreign trade services